Cut electricity consumption with automation - Watt Now Magazine

Cut electricity consumption with automation - Watt Now Magazine

Cut electricity consumption with automation - Watt Now Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Now</strong> you can build an<br />

entire machine on a<br />

microchip - and it works<br />

By Peter Middleton<br />

Micro-electro-mechanical systems or MEMS — also<br />

known as micromachines in Japan or micro systems<br />

technology (MST) in Europe – uses minute components,<br />

typically between one and one hundred microns for<br />

devices that range from twenty microns to one millimetre.<br />

MEMS is the integration of mechanical elements, sensors, actuators,<br />

and electronics onto a common silicon substrate through modern<br />

micro-manufacturing. The technology — based on the technology<br />

developed for integrated circuits (ICs) — places moving mechanical<br />

mechanisms on the same chips and on the same scale as their electronic<br />

controllers. It is a way of making complex electromechanical systems<br />

using batch fabrication methods similar to those used for ICs, but<br />

merging the electromechanical elements <strong>with</strong> the electronics.<br />

MEMS accelerometers are quickly replacing the conventional<br />

bulky devices used for air-bag systems in motorcars — because they<br />

are much smaller, more functional, lighter, more reliable, and are<br />

produced at a fraction of the cost. They are used for communications<br />

devices, electrical components<br />

such as inductors and tunable<br />

capacitors and mechanical<br />

micro-switches, which have<br />

huge potential in various<br />

microwave circuits. MEMS<br />

biochips are also being used<br />

for the detection of hazardous<br />

chemical and biological agents<br />

and in micro-systems for highthroughput<br />

drug screening and<br />

selection.<br />

In a paper presented at<br />

the recent 9th international<br />

tribology conference held<br />

in Pretoria, Professor John<br />

Williams of the Cambridge<br />

University Engineering<br />

Department, described one<br />

of the more spectacular<br />

MEMS applications, The Texas<br />

Instrument Digital Micro-mirror Device. It consists of an array of<br />

microscopically small, square aluminium mirrors — totalling more<br />

than half a million — in an area of about 1,5 square centimetres.<br />

Each mirror is approximately 20 μm by 20 μm and corresponds<br />

to a single pixel on a projected display: Each can be individually<br />

addressed and rotated about one or other of its diagonals through an<br />

angle of about 20° at a frequency of more than 100 kHz. These are<br />

now routinely used in data-projectors.<br />

Williams went on to describe the range of micro-actuators for<br />

the conversion of electrical energy into mechanical movement.<br />

Electrostatic comb motors, the standard prime-movers in MEMS<br />

machines, have a set of fixed combs or ‘fingers’ interwoven <strong>with</strong><br />

second set, which is able to move. By applying an AC-voltage across<br />

the two capacitive elements, reciprocating motion is achieved at very<br />

high conversion efficiencies.<br />

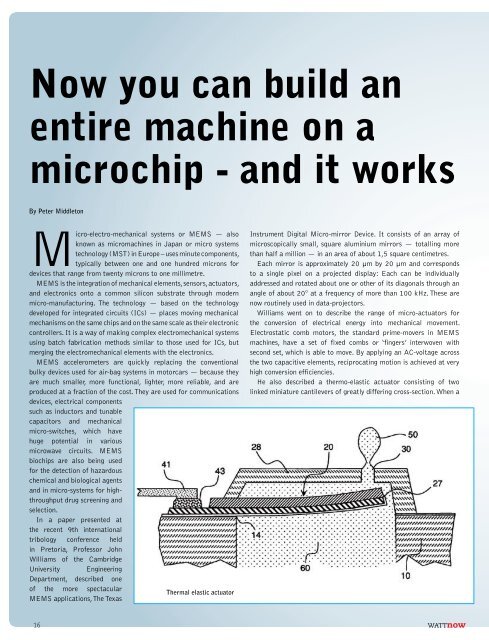

He also described a thermo-elastic actuator consisting of two<br />

linked miniature cantilevers of greatly differing cross-section. When a<br />

16