Bowhunting 2007

Bowhunting 2007

Bowhunting 2007

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

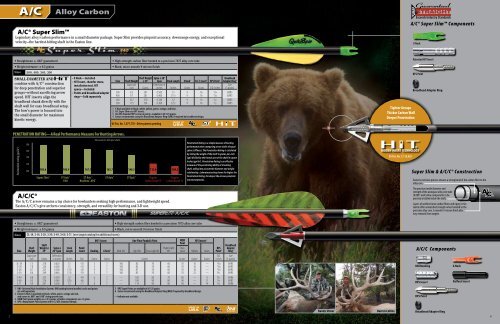

A/C<br />

Alloy Carbon<br />

A/C® Super Slim<br />

Legendary alloy/carbon performance in a small diameter package. Super Slim provides pinpoint accuracy, downrange energy, and exceptional<br />

velocity—the hardest-hitting shaft in the Easton line.<br />

Exceeds Industry Standards<br />

A/C® Super Slim Components<br />

X Nock<br />

• Straightness: ± .002" guaranteed<br />

• Weight tolerance: ± 0.5 grains<br />

Sizes 500, 400, 340, 300<br />

Small-diameter and<br />

combine with A/C ® construction<br />

for deep penetration and superior<br />

groups—without sacrificing arrow<br />

speed. HIT inserts align the<br />

broadhead shank directly with the<br />

shaft wall for easy broadhead setup.<br />

The bow’s power is focused into<br />

the small diameter for maximum<br />

kinetic energy.<br />

• X Nock—Installed<br />

• HIT Insert, chamfer stone,<br />

installation tool, HIT<br />

epoxy—Included<br />

• Points and broadhead adapter<br />

rings—Sold separately<br />

• High-strength carbon fiber bonded to a precision 7075 alloy core tube<br />

• Black, micro-smooth 9-micron finish<br />

Size<br />

500<br />

400<br />

340<br />

300<br />

Shaft Weight<br />

Grains per<br />

inch<br />

8.5<br />

9.7<br />

10.7<br />

11.5<br />

Shaft Weight<br />

@ 29"<br />

Grains<br />

247<br />

281<br />

310<br />

334<br />

Spine @ 28"<br />

Span Stock Length X Nock 1 H.I.T. Insert 2 RPS Point 3 Broadhead<br />

Adapter Ring 4<br />

Deflection in<br />

inches Inches Grains Grains O.D. Inches<br />

Size<br />

(3 grains)<br />

0.500 31<br />

9<br />

16<br />

17<br />

⁄64<br />

BAR3<br />

0.400 31 1 ⁄2<br />

9<br />

16<br />

17<br />

⁄64<br />

BAR3<br />

0.340 32<br />

9<br />

16<br />

9<br />

⁄32<br />

BAR5<br />

0.300 32 1 ⁄2<br />

9<br />

16<br />

9<br />

⁄32<br />

BAR5<br />

1 X Nock available in black, white, yellow, green, orange, and blue.<br />

2 A/C Super Slim uses HIT inserts.<br />

3 Use ATA Standard RPS screw-in points, available in 50-125 grains.<br />

4 Easton recommends using the Broadhead Adapter Ring (BAR) if required by broadhead design.<br />

US Pat. No. 7,077,770 - Other patents pending<br />

Tighter Groups<br />

Thicker Carbon Wall<br />

Deeper Penetration<br />

Patented HIT Insert<br />

RPS Point<br />

Broadhead Adapter Ring<br />

PENETRATION Rating—A Real Performance Measure For Hunting Arrows.<br />

Penetration rating (gpi/in 2 )<br />

180<br />

160<br />

140<br />

120<br />

100<br />

183.6 183.4<br />

Super Slim <br />

ST Axis <br />

FMJ<br />

Measured for 400 spine shafts<br />

167.1 163.7<br />

A/C/C®<br />

The A/C/C arrow remains a top choice for bowhunters seeking high-performance, and lightweight speed.<br />

Easton A/C/C’s give archers consistency, strength, and versatility for hunting and 3-D use.<br />

140.3<br />

ST Axis <br />

ST Axis ST Epic Regular<br />

Realtree ® APG Carbon Brand “A”<br />

112.6 108.2<br />

Regular<br />

Carbon Brand “B”<br />

Penetration Rating is a simple measure of hunting<br />

performance when comparing arrow shafts of equal<br />

spine (stiffness). The Penetration Rating is calculated<br />

by taking the weight of the shaft in grains-per-inch<br />

(gpi) divided by the frontal area of the shaft in square<br />

inches (gpi/in 2 ). Penetration Rating is an effective<br />

measure of the penetrating ability of a hunting<br />

shaft, taking into account the diameter and weight<br />

relationship. Laboratory testing shows the higher the<br />

Penetration Rating, the deeper the arrows penetrate<br />

into test materials.<br />

US Pat. No. 7,115,055<br />

Super Slim & A/C/C® Construc tion<br />

Easton’s exclusive process ensures a strong bond of the carbon fiber to the<br />

alloy core.<br />

The precision inside diameter and<br />

strength of the aerospace alloy core tube<br />

(0.008" wall) allow components to be<br />

precisely installed inside the shaft.<br />

Layers of unidirectional carbon fibers and epoxy-resin<br />

matrix offer unmatched strength when bonded to the<br />

precision alloy core. A smooth 9-micron finish allows<br />

easy removal from targets.<br />

• Straightness: ± .002" guaranteed<br />

• Weight tolerance: ± 0.5 grains<br />

Sizes<br />

Size<br />

3L-18<br />

3-18<br />

3-28<br />

3-39<br />

3-49<br />

3-60<br />

3-71<br />

3L-18, 3-18, 3-28, 3-39, 3-49, 3-60, 3-71 (see target catalog for additional sizes)<br />

Shaft<br />

Weight<br />

Grains per<br />

Inch<br />

7.5<br />

7.8<br />

8.1<br />

8.6<br />

8.8<br />

9.5<br />

9.9<br />

Shaft<br />

Weight @<br />

29"<br />

Grains<br />

218<br />

226<br />

235<br />

249<br />

255<br />

276<br />

287<br />

Spine @<br />

28" Span<br />

Stock<br />

Length<br />

Point/<br />

Insert<br />

• High-strength carbon fiber bonded to a precision 7075 alloy core tube<br />

• Black, micro-smooth 9-micron finish<br />

UNI 1 System One-Piece Parabolic Point NIBB<br />

Point<br />

Bushing G Nock 2 Med. Wt. Light Wt. Extra Light Wt.<br />

RPS Inserts 4<br />

Hyper Light Twopiece<br />

Halfout Wt. Alum.<br />

Deflection<br />

O.D.<br />

in Inches Inches Size Grains Grains Grains 3 Grains 3 Grains 3 Grains 3 Inches<br />

0.620<br />

0.560<br />

0.500<br />

0.440<br />

0.390<br />

0.340<br />

0.300<br />

31<br />

31<br />

31 1 ⁄2<br />

31 1 ⁄2<br />

-18<br />

-18<br />

-28<br />

-39<br />

32 -49<br />

32½ -60<br />

33 -71<br />

1 UNI–Universal Nock Installation System. UNI bushing factory installed, nocks and points<br />

are sold separately.<br />

2 Easton G Nock is available in black, white, green, orange and red,<br />

and comes in .088" and .098" string groove sizes.<br />

3 NIBB Point grain weights are ±0.5 grains; all other components are ±1 grain.<br />

4 RPS=Replaceable Point System with 8-32 ATA Standard thread.<br />

3<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

7<br />

7<br />

7<br />

7<br />

7<br />

7<br />

7<br />

100<br />

100<br />

100<br />

100<br />

—<br />

—<br />

—<br />

82<br />

82<br />

87<br />

85<br />

100<br />

108<br />

114<br />

70<br />

70<br />

70<br />

70<br />

80<br />

90<br />

90<br />

60<br />

60<br />

60<br />

60<br />

70<br />

80<br />

80<br />

70<br />

70<br />

70<br />

70<br />

80<br />

90<br />

90<br />

16<br />

16<br />

18<br />

22<br />

—<br />

—<br />

—<br />

5 RPS Target Points are available in 50-125 grains.<br />

6 Easton recommends using the Broadhead Adapter Ring (BAR) if required by broadhead design.<br />

—Indicates not available.<br />

—<br />

—<br />

—<br />

—<br />

9<br />

11<br />

14<br />

RPS<br />

Point 5<br />

17 ⁄64<br />

17 ⁄64<br />

17 ⁄64<br />

9 ⁄32<br />

9 ⁄32<br />

5 ⁄16<br />

5 ⁄16<br />

Broadhead<br />

Adapter<br />

Ring 6<br />

Size<br />

(3 grains)<br />

BAR3<br />

BAR3<br />

BAR3<br />

BAR5<br />

BAR6<br />

BAR7<br />

BAR8<br />

A/C/C Components<br />

UNI Bushing<br />

G Nock<br />

RPS Insert<br />

Halfout Insert<br />

RPS Point<br />

<br />

Randy Ulmer<br />

Darren Collins<br />

Broadhead Adapter Ring