Seal-Lok⢠O-Ring Face Seal Tube Fittings zfc21 ... - LSR Distribuidor

Seal-Lok⢠O-Ring Face Seal Tube Fittings zfc21 ... - LSR Distribuidor

Seal-Lok⢠O-Ring Face Seal Tube Fittings zfc21 ... - LSR Distribuidor

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4300 Catalog <strong>Seal</strong>-Lok O-<strong>Ring</strong> <strong>Face</strong> <strong>Seal</strong> <strong>Tube</strong> <strong>Fittings</strong><br />

Versatility<br />

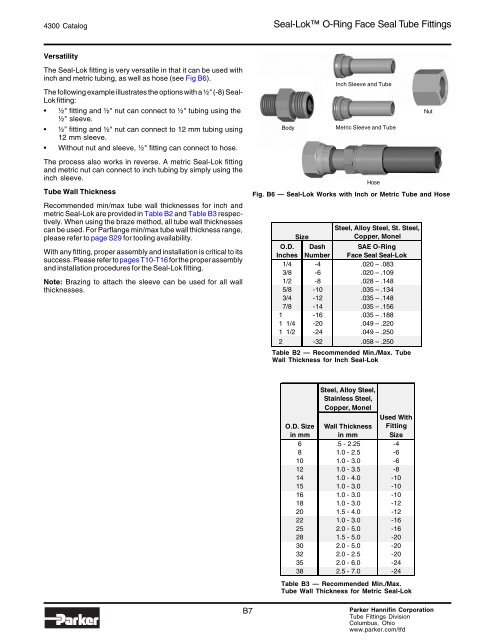

The <strong>Seal</strong>-Lok fitting is very versatile in that it can be used with<br />

inch and metric tubing, as well as hose (see Fig B6).<br />

The following example illustrates the options with a ½" (-8) <strong>Seal</strong>-<br />

Lok fitting:<br />

• ½" fitting and ½" nut can connect to ½" tubing using the<br />

½" sleeve.<br />

• ½” fitting and ½" nut can connect to 12 mm tubing using<br />

12 mm sleeve.<br />

• Without nut and sleeve, ½" fitting can connect to hose.<br />

The process also works in reverse. A metric <strong>Seal</strong>-Lok fitting<br />

and metric nut can connect to inch tubing by simply using the<br />

inch sleeve.<br />

<strong>Tube</strong> Wall Thickness<br />

Recommended min/max tube wall thicknesses for inch and<br />

metric <strong>Seal</strong>-Lok are provided in Table B2 and Table B3 respectively.<br />

When using the braze method, all tube wall thicknesses<br />

can be used. For Parflange min/max tube wall thickness range,<br />

please refer to page S29 for tooling availability.<br />

With any fitting, proper assembly and installation is critical to its<br />

success. Please refer to pages T10-T16 for the proper assembly<br />

and installation procedures for the <strong>Seal</strong>-Lok fitting.<br />

Note: Brazing to attach the sleeve can be used for all wall<br />

thicknesses.<br />

Body<br />

Inch Sleeve and <strong>Tube</strong><br />

Metric Sleeve and <strong>Tube</strong><br />

Hose<br />

Fig. B6 — <strong>Seal</strong>-Lok Works with Inch or Metric <strong>Tube</strong> and Hose<br />

Steel, Alloy Steel, St. Steel,<br />

Size<br />

Copper, Monel<br />

O.D. Dash SAE O-<strong>Ring</strong><br />

Inches Number <strong>Face</strong> <strong>Seal</strong> <strong>Seal</strong>-Lok<br />

1/4 -4 .020 – .083<br />

3/8 -6 .020 – .109<br />

1/2 -8 .028 – .148<br />

5/8 -10 .035 – .134<br />

3/4 -12 .035 – .148<br />

7/8 -14 .035 – .156<br />

1 -16 .035 – .188<br />

1 1/4 -20 .049 – .220<br />

1 1/2 -24 .049 – .250<br />

2 -32 .058 – .250<br />

Table B2 — Recommended Min./Max. <strong>Tube</strong><br />

Wall Thickness for Inch <strong>Seal</strong>-Lok<br />

Nut<br />

O.D. Size<br />

in mm<br />

Steel, Alloy Steel,<br />

Stainless Steel,<br />

Copper, Monel<br />

Used With<br />

Fitting<br />

Size<br />

Wall Thickness<br />

in mm<br />

6 .5 - 2.25 -4<br />

8 1.0 - 2.5 -6<br />

10 1.0 - 3.0 -6<br />

12 1.0 - 3.5 -8<br />

14 1.0 - 4.0 -10<br />

15 1.0 - 3.0 -10<br />

16 1.0 - 3.0 -10<br />

18 1.0 - 3.0 -12<br />

20 1.5 - 4.0 -12<br />

22 1.0 - 3.0 -16<br />

25 2.0 - 5.0 -16<br />

28 1.5 - 5.0 -20<br />

30 2.0 - 5.0 -20<br />

32 2.0 - 2.5 -20<br />

35 2.0 - 6.0 -24<br />

38 2.5 - 7.0 -24<br />

Table B3 — Recommended Min./Max.<br />

<strong>Tube</strong> Wall Thickness for Metric <strong>Seal</strong>-Lok<br />

B7<br />

Parker Hannifin Corporation<br />

<strong>Tube</strong> <strong>Fittings</strong> Division<br />

Columbus, Ohio<br />

www.parker.com/tfd