Gopromotional - The Complete Guide To Umbrellas

GoPromotional are a leading UK supplier of promotional umbrellas - see our latest range of products and specifications.

GoPromotional are a leading UK supplier of promotional umbrellas - see our latest range of products and specifications.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

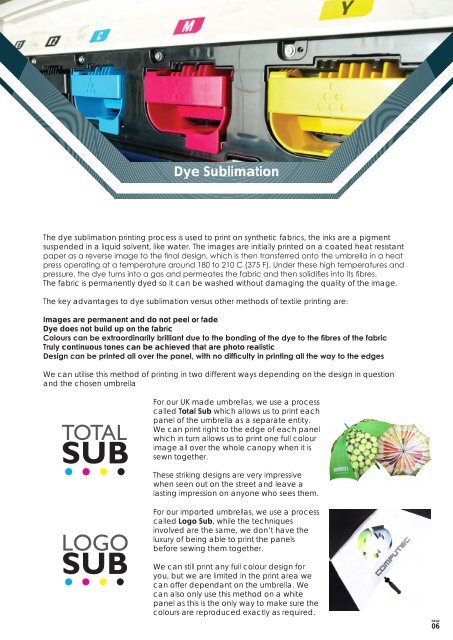

Dye Sublimation<br />

<strong>The</strong> dye sublimation printing process is used to print on synthetic fabrics, the inks are a pigment<br />

suspended in a liquid solvent, like water. <strong>The</strong> images are initially printed on a coated heat resistant<br />

paper as a reverse image to the final design, which is then transferred onto the umbrella in a heat<br />

press operating at a temperature around 180 to 210 C (375 F). Under these high temperatures and<br />

pressure, the dye turns into a gas and permeates the fabric and then solidifies into its fibres.<br />

<strong>The</strong> fabric is permanently dyed so it can be washed without damaging the quality of the image.<br />

<strong>The</strong> key advantages to dye sublimation versus other methods of textile printing are:<br />

Images are permanent and do not peel or fade<br />

Dye does not build up on the fabric<br />

Colours can be extraordinarily brilliant due to the bonding of the dye to the fibres of the fabric<br />

Truly continuous tones can be achieved that are photo realistic<br />

Design can be printed all over the panel, with no difficulty in printing all the way to the edges<br />

We can utilise this method of printing in two different ways depending on the design in question<br />

and the chosen umbrella<br />

For our UK made umbrellas, we use a process<br />

called <strong>To</strong>tal Sub which allows us to print each<br />

panel of the umbrella as a separate entity.<br />

We can print right to the edge of each panel<br />

which in turn allows us to print one full colour<br />

image all over the whole canopy when it is<br />

sewn together.<br />

<strong>The</strong>se striking designs are very impressive<br />

when seen out on the street and leave a<br />

lasting impression on anyone who sees them.<br />

For our imported umbrellas, we use a process<br />

called Logo Sub, while the techniques<br />

involved are the same, we don’t have the<br />

luxury of being able to print the panels<br />

before sewing them together.<br />

We can still print any full colour design for<br />

you, but we are limited in the print area we<br />

can offer dependant on the umbrella. We<br />

can also only use this method on a white<br />

panel as this is the only way to make sure the<br />

colours are reproduced exactly as required.<br />

PAGE<br />

06