Synthetic Slings - Hanes Supply, Inc

Synthetic Slings - Hanes Supply, Inc

Synthetic Slings - Hanes Supply, Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

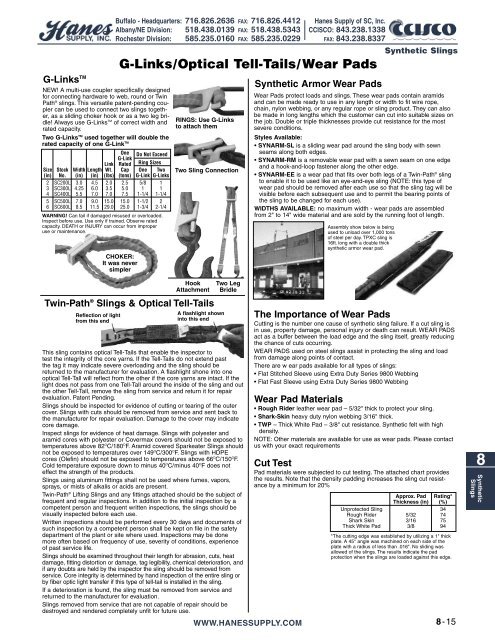

G-Links TM<br />

NEW! A multi-use coupler specifically designed<br />

for connecting hardware to web, round or Twin<br />

Path ® slings. This versatile patent-pending coupler<br />

can be used to connect two slings together,<br />

as a sliding choker hook or as a two leg bridle!<br />

Always use G-Links TM of correct width and<br />

rated capacity.<br />

Two G-Links TM used together will double the<br />

rated capacity of one G-Link TM<br />

One Do Not Exceed<br />

G-Link<br />

Link Rated Ring Sizes<br />

Size Stock Width Length Wt. Cap One Two<br />

(in) No. (in) (in) (lbs) (tons) G-Link G-Links<br />

2 SC200L 3.0 4.5 2.0 2.5 5/8 1<br />

3 SC300L 4.25 6.0 3.5 5.0 1 1<br />

4 SC400L 5.5 7.0 7.0 7.5 1-1/4 1-1/4<br />

5 SC500L 7.0 9.0 15.0 15.0 1-1/2 2<br />

6 SC600L 8.5 11.5 29.0 25.0 1-3/4 2-1/4<br />

WARNING! Can fail if damaged misused or overloaded.<br />

Inspect before use. Use only if trained. Observe rated<br />

capacity. DEATH or INJURY can occur from improper<br />

use or maintenance.<br />

Buffalo - Headquarters: 716.826.2636 FAX: 716.826.4412<br />

Albany/NE Division: 518.438.0139 FAX: 518.438.5343<br />

Rochester Division: 585.235.0160 FAX: 585.235.0229<br />

G-Links/Optical Tell-Tails/ Wear Pads<br />

CHOKER:<br />

It was never<br />

simpler<br />

RINGS: Use G-Links<br />

to attach them<br />

Two Sling Connection<br />

<strong>Hanes</strong> <strong>Supply</strong> of SC, <strong>Inc</strong>.<br />

CCISCO: 843.238.1338<br />

FAX: 843.238.8337<br />

<strong>Synthetic</strong> <strong>Slings</strong><br />

<strong>Synthetic</strong> Armor Wear Pads<br />

Wear Pads protect loads and slings. These wear pads contain aramids<br />

and can be made ready to use in any length or width to fit wire rope,<br />

chain, nylon webbing, or any regular rope or sling product. They can also<br />

be made in long lengths which the customer can cut into suitable sizes on<br />

the job. Double or triple thicknesses provide cut resistance for the most<br />

severe conditions.<br />

Styles Available:<br />

• SYNARM-SL is a sliding wear pad around the sling body with sewn<br />

seams along both edges.<br />

• SYNARM-RM is a removable wear pad with a sewn seam on one edge<br />

and a hook-and-loop fastener along the other edge.<br />

• SYNARM-EE is a wear pad that fits over both legs of a Twin-Path ® sling<br />

to enable it to be used like an eye-and-eye sling (NOTE: this type of<br />

wear pad should be removed after each use so that the sling tag will be<br />

visible before each subsequent use and to permit the bearing points of<br />

the sling to be changed for each use).<br />

WIDTHS AVAILABLE: no maximum width - wear pads are assembled<br />

from 2" to 14" wide material and are sold by the running foot of length.<br />

Assembly show below is being<br />

used to unload over 1,000 tons<br />

of steel per day. TPXC sling is<br />

16ft. long with a double thick<br />

synthetic armor wear pad.<br />

Hook<br />

Attachment<br />

Twin-Path ® <strong>Slings</strong> & Optical Tell-Tails<br />

Reflection of light<br />

from this end<br />

A flashlight shown<br />

into this end<br />

Two Leg<br />

Bridle<br />

This sling contains optical Tell-Tails that enable the inspector to<br />

test the integrity of the core yarns. If the Tell-Tails do not extend past<br />

the tag it may indicate severe overloading and the sling should be<br />

returned to the manufacturer for evaluation. A flashlight shone into one<br />

optical Tell-Tall will reflect from the other if the core yarns are intact. If the<br />

light does not pass from one Tell-Tall around the inside of the sling and out<br />

the other Tell-Tall, remove the sling from service and return it for repair<br />

evaluation. Patent Pending.<br />

<strong>Slings</strong> should be inspected for evidence of cutting or tearing of the outer<br />

cover. <strong>Slings</strong> with cuts should be removed from service and sent back to<br />

the manufacturer for repair evaluation. Damage to the cover may indicate<br />

core damage.<br />

Inspect slings for evidence of heat damage. <strong>Slings</strong> with polyester and<br />

aramid cores with polyester or Covermax covers should not be exposed to<br />

temperatures above 82 O C/180 O F. Aramid covered Sparkeater <strong>Slings</strong> should<br />

not be exposed to temperatures over 149 O C/300 O F. <strong>Slings</strong> with HDPE<br />

cores (Olefin) should not be exposed to temperatures above 66 O C/150 O F.<br />

Cold temperature exposure down to minus 40 O C/minus 40 O F does not<br />

effect the strength of the products.<br />

<strong>Slings</strong> using aluminum fittings shall not be used where fumes, vapors,<br />

sprays, or mists of alkalis or acids are present.<br />

Twin-Path ® Lifting <strong>Slings</strong> and any fittings attached should be the subject of<br />

frequent and regular inspections. In addition to the initial inspection by a<br />

competent person and frequent written inspections, the slings should be<br />

visually inspected before each use.<br />

Written inspections should be performed every 30 days and documents of<br />

such inspection by a competent person shall be kept on file in the safety<br />

department of the plant or site where used. Inspections may be done<br />

more often based on frequency of use, severity of conditions, experience<br />

of past service life.<br />

<strong>Slings</strong> should be examined throughout their length for abrasion, cuts, heat<br />

damage, fitting distortion or damage, tag legibility, chemical deterioration, and<br />

if any doubts are held by the inspector the sling should be removed from<br />

service. Core integrity is determined by hand inspection of the entire sling or<br />

by fiber optic light transfer if this type of tell-tail is installed in the sling.<br />

If a deterioration is found, the sling must be removed from service and<br />

returned to the manufacturer for evaluation.<br />

<strong>Slings</strong> removed from service that are not capable of repair should be<br />

destroyed and rendered completely unfit for future use.<br />

WWW.HANESSUPPLY.COM<br />

The Importance of Wear Pads<br />

Cutting is the number one cause of synthetic sling failure. If a cut sling is<br />

in use, property damage, personal injury or death can result. WEAR PADS<br />

act as a buffer between the load edge and the sling itself, greatly reducing<br />

the chance of cuts occurring.<br />

WEAR PADS used on steel slings assist in protecting the sling and load<br />

from damage along points of contact.<br />

There are w ear pads available for all types of slings:<br />

• Flat Stitched Sleeve using Extra Duty Series 9800 Webbing<br />

• Flat Fast Sleeve using Extra Duty Series 9800 Webbing<br />

Wear Pad Materials<br />

• Rough Rider leather wear pad – 5/32" thick to protect your sling.<br />

• Shark-Skin heavy duty nylon webbing 3/16" thick.<br />

• TWP – Thick White Pad – 3/8" cut resistance. <strong>Synthetic</strong> felt with high<br />

density.<br />

NOTE: Other materials are available for use as wear pads. Please contact<br />

us with your exact requirements<br />

Cut Test<br />

Pad materials were subjected to cut testing. The attached chart provides<br />

the results. Note that the density padding increases the sling cut resistance<br />

by a minimum for 20%<br />

Approx. Pad Rating*<br />

Thickness (in) (%)<br />

Unprotected Sling 34<br />

Rough Rider 5/32 74<br />

Shark Skin 3/16 75<br />

Thick White Pad 3/8 94<br />

*The cutting edge was established by utilizing a 1" thick<br />

plate. A 45° angle was machined on each side of the<br />

plate with a radius of less than .016". No sliding was<br />

allowed of the slings. The results indicate the pad<br />

protection when the slings are loaded against this edge.<br />

8-15<br />

8<br />

<strong>Synthetic</strong><br />

<strong>Slings</strong>