feed technology upda feed technology updatete - AquaFeed.com

feed technology upda feed technology updatete - AquaFeed.com

feed technology upda feed technology updatete - AquaFeed.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

AQUAFEED PROCESSING<br />

twin screw extruder is 1.5 to 2 times the<br />

cost of a state-of-the-art single screw extruder<br />

with <strong>com</strong>parable hourly production<br />

capacity.<br />

Because of the increased costs, only those<br />

<strong>feed</strong> products with strong value added potential<br />

are processed via the twin screw extruder.<br />

Specific product characteristics or processing<br />

requirements where twin screw extrusion<br />

systems have found applications are as<br />

follows:<br />

1. Ultra-high fat <strong>feed</strong>s (above 17 percent<br />

internal fat)<br />

2. Products which have high levels of fresh<br />

meat or other high moisture slurries (above<br />

35 percent).<br />

3. Uniform shape/size product (portioned<br />

foods)<br />

4. Ultra-small products (0.6 to 2.0 mm diameter<br />

products)<br />

5. Co-extruded products (<strong>com</strong>plex pet food<br />

treats)<br />

In those cases where twin screw extrusion<br />

for aquatic <strong>feed</strong>s is justified however, the<br />

previously mentioned processing requirements<br />

have led extruder manufacturers to<br />

design twin screw extruders (Figure 1) and<br />

ancillary <strong>com</strong>ponents capable of covering an<br />

extreme range of processing applications.<br />

One example of this new breed of parallelshaft,<br />

twin screw extruders is the Magnum<br />

ST series, developed by Wenger Manufacturing,<br />

Inc.<br />

With maximum speeds up to 1,200 rpm<br />

and power levels up to 165 kWh/t SME at<br />

volumetric capacity (Table 1), the Magnum<br />

ST Series provides optimum extrusion versatility.<br />

These economical, high capacity extruders<br />

allow processors to utilize a smaller extruder<br />

model without sacrificing capacity.<br />

Alternatively, the higher SME capabilities<br />

can be utilized to meet unique product requirements.<br />

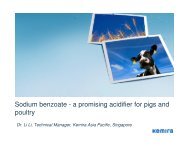

C 2 TX EXTRUDER<br />

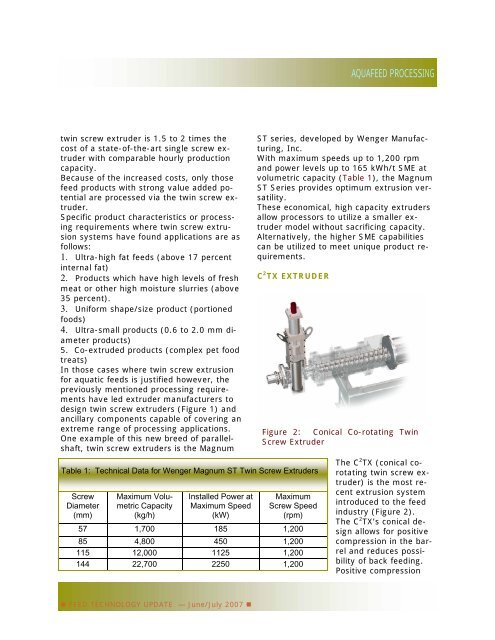

Table 1: Technical Data for Wenger Magnum ST Twin Screw Extruders<br />

Screw<br />

Diameter<br />

(mm)<br />

Maximum Volumetric<br />

Capacity<br />

(kg/h)<br />

Installed Power at<br />

Maximum Speed<br />

(kW)<br />

• FEED TECHNOLOGY UPDATE — November 2006 •<br />

• FEED TECHNOLOGY UPDATE — June/July 2007 •<br />

Maximum<br />

Screw Speed<br />

(rpm)<br />

57 1,700 185 1,200<br />

85 4,800 450 1,200<br />

115 12,000 1125 1,200<br />

144 22,700 2250 1,200<br />

Figure 2: Conical Co-rotating Twin<br />

Screw Extruder<br />

The C 2 TX (conical corotating<br />

twin screw extruder)<br />

is the most recent<br />

extrusion system<br />

introduced to the <strong>feed</strong><br />

industry (Figure 2).<br />

The C 2 TX’s conical design<br />

allows for positive<br />

<strong>com</strong>pression in the barrel<br />

and reduces possibility<br />

of back <strong>feed</strong>ing.<br />

Positive <strong>com</strong>pression