£17 .50

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4 The Timber Mill<br />

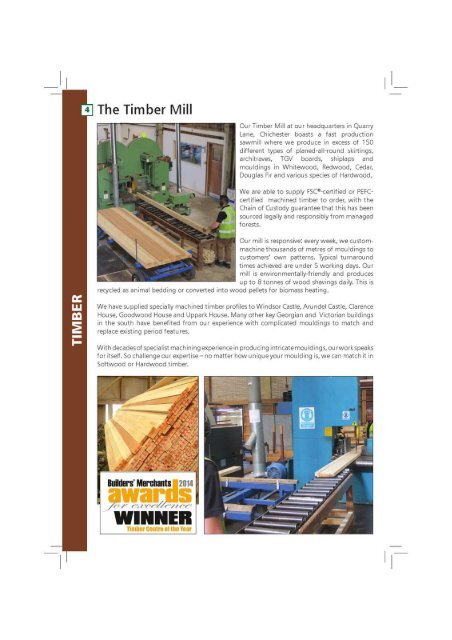

Our Timber Mill at our headquarters in Quarry<br />

Lane, Chichester boasts a fast production<br />

sawmill where we produce in excess of 150<br />

different types of planed-all-round skirtings,<br />

architraves, TGV boards, shiplaps and<br />

mouldings in Whitewood, Redwood, Cedar,<br />

Douglas Fir and various species of Hardwood.<br />

We are able to supply FSC ® -certified or PEFCcertified<br />

machined timber to order, with the<br />

Chain of Custody guarantee that this has been<br />

sourced legally and responsibly from managed<br />

forests.<br />

TIMBER<br />

Our mill is responsive: every week, we custommachine<br />

thousands of metres of mouldings to<br />

customers’ own patterns. Typical turnaround<br />

times achieved are under 5 working days. Our<br />

mill is environmentally-friendly and produces<br />

up to 8 tonnes of wood shavings daily. This is<br />

recycled as animal bedding or converted into wood pellets for biomass heating.<br />

We have supplied specially machined timber profiles to Windsor Castle, Arundel Castle, Clarence<br />

House, Goodwood House and Uppark House. Many other key Georgian and Victorian buildings<br />

in the south have benefited from our experience with complicated mouldings to match and<br />

replace existing period features.<br />

With decades of specialist machining experience in producing intricate mouldings, our work speaks<br />

for itself. So challenge our expertise – no matter how unique your moulding is, we can match it in<br />

Softwood or Hardwood timber.