ESW - Surplus Used Equipment

ESW - Surplus Used Equipment

ESW - Surplus Used Equipment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

E NERGY E FFICIENT L OW S OUND<br />

The <strong>ESW</strong> line of closed circuit coolers represents<br />

Evapco’s continuous commitment to developing<br />

innovative products which surpass industry standards<br />

and expectations. This time, Evapco has added super<br />

efficiency and low sound to the serviceability benefits<br />

of Evapco’s Advanced Technology product line.<br />

Low Energy As Standard<br />

The <strong>ESW</strong> stands apart as being the most energy<br />

efficient closed circuit cooler ever. This efficiency, in<br />

terms of lower fan horsepower, translates directly to<br />

lower operating costs…significantly lower operating<br />

costs. With the <strong>ESW</strong> installed, customers can realize<br />

immediate energy savings which continue each and<br />

every year for the life of the equipment.<br />

• Replace inefficient units:<br />

The potential for energy savings alone is often<br />

enough to justify replacing inefficient fluid coolers<br />

with high efficiency models. As an example, a 250<br />

ton centrifugal fan fluid cooler with 80 HP worth of<br />

fan motors can be replaced by an <strong>ESW</strong> model with a<br />

fan motor size of only 15HP. This tremendous<br />

reduction in fan motor size offers annual savings of<br />

$16,530 per year based on 3,500 hours of operation<br />

and an electric rate of $0.09/kwhr.<br />

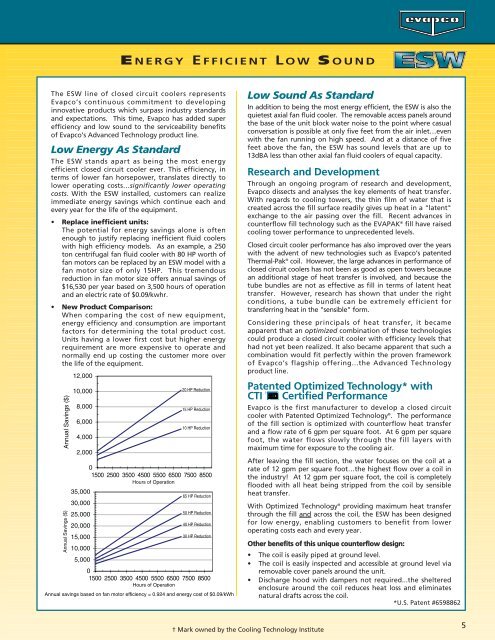

• New Product Comparison:<br />

When comparing the cost of new equipment,<br />

energy efficiency and consumption are important<br />

factors for determining the total product cost.<br />

Units having a lower first cost but higher energy<br />

requirement are more expensive to operate and<br />

normally end up costing the customer more over<br />

the life of the equipment.<br />

Annual Savings ($)<br />

Annual Savings ($)<br />

12,000<br />

10,000<br />

8,000<br />

6,000<br />

4,000<br />

2,000<br />

35,000<br />

30,000<br />

25,000<br />

20,000<br />

15,000<br />

10,000<br />

5,000<br />

20 HP Reduction<br />

15 HP Reduction<br />

10 HP Reduction<br />

0<br />

1500 2500 3500 4500 5500 6500 7500 8500<br />

Hours of Operation<br />

65 HP Reduction<br />

50 HP Reduction<br />

40 HP Reduction<br />

30 HP Reduction<br />

0<br />

1500 2500 3500 4500 5500 6500 7500 8500<br />

Hours of Operation<br />

Annual savings based on fan motor efficiency = 0.924 and energy cost cost of of $0.09/kWh<br />

Low Sound As Standard<br />

In addition to being the most energy efficient, the <strong>ESW</strong> is also the<br />

quietest axial fan fluid cooler. The removable access panels around<br />

the base of the unit block water noise to the point where casual<br />

conversation is possible at only five feet from the air inlet…even<br />

with the fan running on high speed. And at a distance of five<br />

feet above the fan, the <strong>ESW</strong> has sound levels that are up to<br />

13dBA less than other axial fan fluid coolers of equal capacity.<br />

Research and Development<br />

Through an ongoing program of research and development,<br />

Evapco dissects and analyses the key elements of heat transfer.<br />

With regards to cooling towers, the thin film of water that is<br />

created across the fill surface readily gives up heat in a "latent"<br />

exchange to the air passing over the fill. Recent advances in<br />

counterflow fill technology such as the EVAPAK ® fill have raised<br />

cooling tower performance to unprecedented levels.<br />

Closed circuit cooler performance has also improved over the years<br />

with the advent of new technologies such as Evapco’s patented<br />

Thermal-Pak ® coil. However, the large advances in performance of<br />

closed circuit coolers has not been as good as open towers because<br />

an additional stage of heat transfer is involved, and because the<br />

tube bundles are not as effective as fill in terms of latent heat<br />

transfer. However, research has shown that under the right<br />

conditions, a tube bundle can be extremely efficient for<br />

transferring heat in the "sensible" form.<br />

Considering these principals of heat transfer, it became<br />

apparent that an optimized combination of these technologies<br />

could produce a closed circuit cooler with efficiency levels that<br />

had not yet been realized. It also became apparent that such a<br />

combination would fit perfectly within the proven framework<br />

of Evapco’s flagship offering...the Advanced Technology<br />

product line.<br />

Patented Optimized Technology* with<br />

†<br />

CTI Certified Performance<br />

Evapco is the first manufacturer to develop a closed circuit<br />

cooler with Patented Optimized Technology ® . The performance<br />

of the fill section is optimized with counterflow heat transfer<br />

and a flow rate of 6 gpm per square foot. At 6 gpm per square<br />

foot, the water flows slowly through the fill layers with<br />

maximum time for exposure to the cooling air.<br />

After leaving the fill section, the water focuses on the coil at a<br />

rate of 12 gpm per square foot…the highest flow over a coil in<br />

the industry! At 12 gpm per square foot, the coil is completely<br />

flooded with all heat being stripped from the coil by sensible<br />

heat transfer.<br />

With Optimized Technology ® providing maximum heat transfer<br />

through the fill and across the coil, the <strong>ESW</strong> has been designed<br />

for low energy, enabling customers to benefit from lower<br />

operating costs each and every year.<br />

Other benefits of this unique counterflow design:<br />

• The coil is easily piped at ground level.<br />

• The coil is easily inspected and accessible at ground level via<br />

removable cover panels around the unit.<br />

• Discharge hood with dampers not required...the sheltered<br />

enclosure around the coil reduces heat loss and eliminates<br />

natural drafts across the coil.<br />

*U.S. Patent #6598862<br />

† Mark owned by the Cooling Technology Institute<br />

5