Roller Cone Bits - Oil & Gas Products 2006-2007 - Varel International

Roller Cone Bits - Oil & Gas Products 2006-2007 - Varel International

Roller Cone Bits - Oil & Gas Products 2006-2007 - Varel International

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

J o u r n a l B e a r i n g F e a t u r e s<br />

For sizes up to 13 ¾" (349.2 mm)<br />

Ball Retention<br />

The Challenger bearing features ball retention, designed<br />

to retain the cone without carrying bit weight. This design<br />

technique prevents ball race spalling failures and extends<br />

bearing life.<br />

Thermally Stable Extreme Pressure (EP) Lubricant<br />

Challenger bearings utilize a thermally stable EP lubricant<br />

formulated to work synergistically with the bearing materials.<br />

The lubricant maintains high relative viscosity even when the<br />

bearings are subject to extreme energy levels in demanding<br />

applications.<br />

Hardmetal Inlays<br />

Hard metal inlays on critical bearing surfaces are precisionmachined<br />

to provide superior bearing performance by reducing<br />

friction and wear.<br />

Precision, Silver-Plated Floating Elements<br />

All bearing surfaces feature precision, silver-plated floating<br />

elements between the cone and head-bearing surfaces. These<br />

floating elements reduce bearing heat generation and prolong<br />

bearing life at higher rotary speeds.<br />

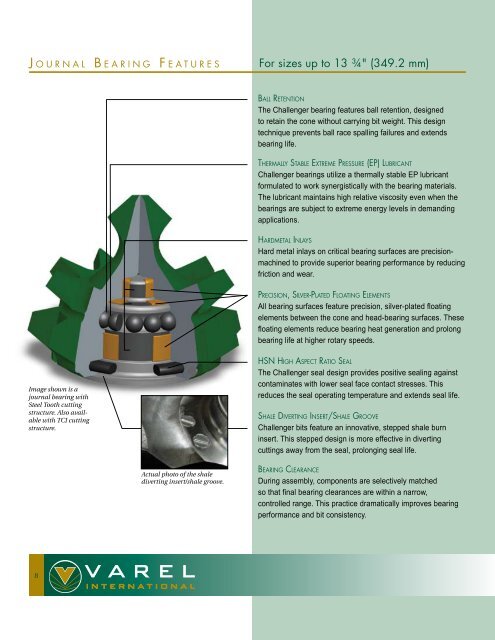

Image shown is a<br />

journal bearing with<br />

Steel Tooth cutting<br />

structure. Also available<br />

with TCI cutting<br />

structure.<br />

HSN High Aspect Ratio Seal<br />

The Challenger seal design provides positive sealing against<br />

contaminates with lower seal face contact stresses. This<br />

reduces the seal operating temperature and extends seal life.<br />

Shale Diverting Insert/Shale Groove<br />

Challenger bits feature an innovative, stepped shale burn<br />

insert. This stepped design is more effective in diverting<br />

cuttings away from the seal, prolonging seal life.<br />

Actual photo of the shale<br />

diverting insert/shale groove.<br />

Bearing Clearance<br />

During assembly, components are selectively matched<br />

so that final bearing clearances are within a narrow,<br />

controlled range. This practice dramatically improves bearing<br />

performance and bit consistency.<br />

8