LEAN FABRIKA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

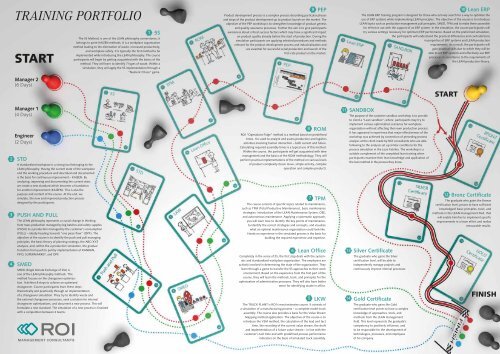

TRAINING PORTFOLIO<br />

START<br />

Manager 2<br />

(6 Days)<br />

5S<br />

The 5S Method, is one of the <strong>LEAN</strong> philosophy cornerstones, it<br />

belongs to point KAIZEN methods. It is a workplace organization<br />

method leading to the elimination of waste, increased productivity,<br />

and workplace safety. It is typically the first method to be<br />

implemented while introducing the <strong>LEAN</strong> philosophy. The course<br />

participants will begin by getting acquainted with the basics of the<br />

method. They will learn to identify 7 types of waste. Within a<br />

simulation, they will apply the 5S implementation through a<br />

“Numeric Chaos” game.<br />

1<br />

PEP<br />

Product development process is a complex process describing particular phases<br />

and steps of the product development up to product launch on the market. The<br />

objective of the PEP workshop is to strengthen knowledge of product genesis<br />

and quality assurance processes. Further the aim is to give participants<br />

awareness about critical success factors which may have a significant impact<br />

on product quality already before the start of production. During the<br />

simulation participants are applying selected procedures and methods<br />

relevant for the product development process and industrialization and<br />

are essential for successful serial production and launch of the<br />

first-rate product on the market.<br />

9<br />

Lean ERP<br />

The <strong>LEAN</strong> ERP training program is designed for those who actively search for a way to optimize the<br />

use of ERP systems while implementing <strong>LEAN</strong> principles. The objective of the course is to introduce<br />

<strong>LEAN</strong> topics such as production management pull principles, SMED, TPM and to make them accessible<br />

for effective use with the support of an ERP system. In the simulation, the course participants will<br />

try various settings necessary for optimum ERP performance. Based on the preformed simulation,<br />

the participants will understand the practical differences and contradictions<br />

in properties of ERP systems and <strong>LEAN</strong> production<br />

requirements. As a result, the participants will<br />

gain practical skills due to which they will be<br />

able to set ERP systems and effectively use ERP<br />

processes in accordance to the requirements of<br />

the <strong>LEAN</strong> production theory.<br />

START<br />

10<br />

2<br />

3<br />

4<br />

Manager 1<br />

(4 Days)<br />

Engineer<br />

(2 Days)<br />

STD<br />

A standardized workplace is a strong tool belonging to the<br />

<strong>LEAN</strong> philosophy. Having the current state of the workplace<br />

and the working procedure well described and documented<br />

is the basis for continuous improvement – KAIZEN. By<br />

analyzing, improving and documenting the current state,<br />

we create a new standard which becomes a foundation<br />

for another improvement (KAIZEN). This is also the<br />

purpose and content of the course. At the end, we<br />

simulate, the new and improved production process<br />

designed by the participants.<br />

PUSH AND PULL<br />

The <strong>LEAN</strong> philosophy represents a crucial change in thinking:<br />

from mass production managed by big batches and safety supplies<br />

(PUSH) to a production managed by the customer’s consumption<br />

(PULL) – ideally heading towards “one piece flow“ (OPF). The<br />

objective of the course is to identify the push and pull managing<br />

principles, the basic theory of planning strategy, the ABC/XYZ<br />

analyses, and, within the a production simulation, the gradual<br />

transition from push to pull by implementation of KANBAN,<br />

FIFO, SUPERMARKET, and OPF.<br />

SMED<br />

SMED (Single Minute Exchange of Die) is<br />

one of the <strong>LEAN</strong> philosophy methods. This<br />

method focuses on the changeover optimization.<br />

It defines 8 steps to achieve an optimized<br />

changeover. Course participants learn these steps<br />

theoretically and practically through an implementation<br />

of a changeover simulation. They try to identify waste and<br />

the external changeover processes, seek a solution for internal<br />

changeover optimizations, and document a new process. This will<br />

formulate a new standard. The simulation of a new process is finalized<br />

with a competition between 2 teams.<br />

ROM<br />

ROI “Operations Folge” method is a method based on predefined<br />

times. It is used to analyze and assess production and logistics<br />

activities involving human interaction – both current and future.<br />

Calculating required assembly times is a typical use of this method.<br />

Within the course, the participants will get acquainted with time<br />

management and the basics of the ROM methodology. They will<br />

perform practical implementations of the method on various levels<br />

of product complexity (basic move, simple activity, complex<br />

operation and complex product).<br />

TPM<br />

The course consists of specific topics related to maintenance,<br />

such as TPM (Total Productive Maintenance), basic maintenance<br />

strategies, introduction of the <strong>LEAN</strong> Maintenance System, OEE,<br />

and autonomous maintenance. Applying a systematic approach,<br />

you will learn how to identify the key points of maintenance,<br />

to identify the correct strategies and concepts, and visualize<br />

what an optimal maintenance organization could look like.<br />

Hands on experience in the simulated process is the basis for<br />

building the required experience and expertise.<br />

8<br />

7<br />

Lean Office<br />

Completely in the sense of 5S, the first step deals with the systematic<br />

and standardized workplace organization. The employees are<br />

actively involved in determining the state of the organization. They<br />

learn through a game to transfer the 5S approaches to their work<br />

environment. Based on the experience from the first part of the<br />

course, they will learn the methods, tools, and principles for the<br />

optimization of administrative processes. They will also have better<br />

sense for identifying waste in office.<br />

6<br />

LKW<br />

The TRUCK PLANT is ROI’s most extensive course. It consists of<br />

a simulation of a manufacturing process – a complete model truck<br />

assembly. The course also provides a basis for the Value Stream<br />

Mapping method application. The objective of the course is to<br />

introduce the VSM method, the calculation of the lead and tact<br />

time, the recording of the current value stream, the draft<br />

and implementation of a future value stream – in line with the<br />

customer’s tact time and with predefined process performance<br />

indicators on the basis of simulated truck assembly.<br />

5<br />

11<br />

13<br />

14<br />

SANDBOX<br />

The purpose of the customer sandbox workshop is to provide<br />

to client a "Lean sandbox", where participants may try to<br />

implement various optimization scenarios for workplace<br />

organization without affecting their own production process.<br />

It has appeared in experience that major effectiveness of the<br />

workshop was achieved by connection of preceding process<br />

analysis at the client made by ROI consultants who are able<br />

following to the analysis set up similar conditions for the<br />

process simulation in the Lean Fabrika. The workshop is a<br />

suitable complement of the completed lean training when<br />

participants examine their lean knowledge and application of<br />

the lean method in the process they know.<br />

Silver Certificate<br />

The graduate who gains the Silver<br />

certification level, will be able to<br />

independently manage projects and<br />

continuously improve internal processes.<br />

Gold Certificate<br />

The graduate who gains the Gold<br />

certification level proves to have a complex<br />

knowledge of approaches, tools, and<br />

methods from the <strong>LEAN</strong> management<br />

field. This level represents the graduate’s<br />

competency to positively influence, and<br />

to be responsible for the development of<br />

technologies, processes, and employees<br />

of his company.<br />

12 Bronz Certificate<br />

The graduate who gains the Bronze<br />

certification level, proves to have sufficient<br />

knowledgeof basic principles, tools, and<br />

methods in the <strong>LEAN</strong> management filed, that<br />

will enable him/her to implement specific<br />

improvements in a team effort and realize<br />

measurable results.<br />

FINISH