Hydrosulfite Types - BASF

Hydrosulfite Types - BASF

Hydrosulfite Types - BASF

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

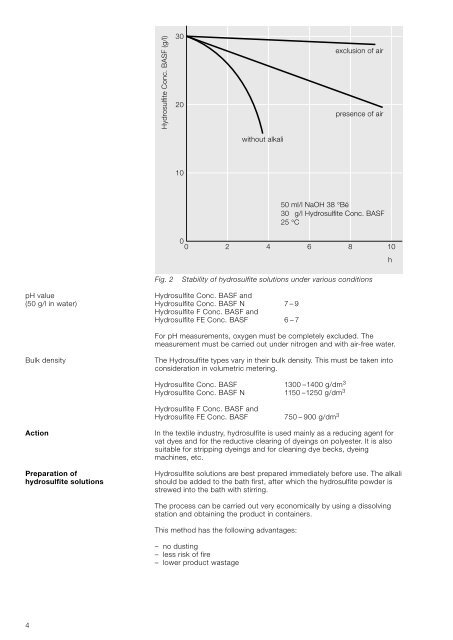

<strong>Hydrosulfite</strong> Conc. <strong>BASF</strong> (g/l)<br />

30<br />

20<br />

exclusion of air<br />

presence of air<br />

without alkali<br />

10<br />

50 ml/l NaOH 38 °Bé<br />

30 g/l <strong>Hydrosulfite</strong> Conc. <strong>BASF</strong><br />

25 °C<br />

0<br />

0 2 4 6 8 10<br />

h<br />

Fig. 2<br />

Stability of hydrosulfite solutions under various conditions<br />

pH value<br />

<strong>Hydrosulfite</strong> Conc. <strong>BASF</strong> and<br />

(50 g/l in water) <strong>Hydrosulfite</strong> Conc. <strong>BASF</strong> N 7– 9<br />

<strong>Hydrosulfite</strong> F Conc. <strong>BASF</strong> and<br />

<strong>Hydrosulfite</strong> FE Conc. <strong>BASF</strong> 6 – 7<br />

For pH measurements, oxygen must be completely excluded. The<br />

measurement must be carried out under nitrogen and with air-free water.<br />

Bulk density<br />

The <strong>Hydrosulfite</strong> types vary in their bulk density. This must be taken into<br />

consideration in volumetric metering.<br />

<strong>Hydrosulfite</strong> Conc. <strong>BASF</strong> 1300 –1400 g/dm 3<br />

<strong>Hydrosulfite</strong> Conc. <strong>BASF</strong> N 1150 –1250 g/dm 3<br />

<strong>Hydrosulfite</strong> F Conc. <strong>BASF</strong> and<br />

<strong>Hydrosulfite</strong> FE Conc. <strong>BASF</strong> 750 – 900 g/dm 3<br />

Action<br />

Preparation of<br />

hydrosulfite solutions<br />

In the textile industry, hydrosulfite is used mainly as a reducing agent for<br />

vat dyes and for the reductive clearing of dyeings on polyester. It is also<br />

suitable for stripping dyeings and for cleaning dye becks, dyeing<br />

machines, etc.<br />

<strong>Hydrosulfite</strong> solutions are best prepared immediately before use. The alkali<br />

should be added to the bath first, after which the hydrosulfite powder is<br />

strewed into the bath with stirring.<br />

The process can be carried out very economically by using a dissolving<br />

station and obtaining the product in containers.<br />

This method has the following advantages:<br />

– no dusting<br />

– less risk of fire<br />

– lower product wastage<br />

4