- Page 2:

This page intentionally left blank

- Page 8:

RFID Technology and Applications Ed

- Page 12:

Contents List of contributors page

- Page 16:

Contents vii 8 Deployment considera

- Page 20:

Contents ix 15.4 ISO 18000-7 and 6c

- Page 26:

xii List of contributors Mohammad H

- Page 30:

xiv List of contributors Dieter Uck

- Page 34:

xvi Preface maximize their readabil

- Page 38:

xviii Preface interoperability stan

- Page 42:

xx Preface hospitals, 5 where suppl

- Page 46:

xxii Acknowledgments Americas. Seve

- Page 52:

1 Introduction to RFID history and

- Page 56:

Introduction to RFID history and ma

- Page 60:

Introduction to RFID history and ma

- Page 64:

Introduction to RFID history and ma

- Page 68:

Introduction to RFID history and ma

- Page 72:

Introduction to RFID history and ma

- Page 76:

Introduction to RFID history and ma

- Page 80:

Introduction to RFID history and ma

- Page 84:

RFID technology and its application

- Page 88:

RFID technology and its application

- Page 92:

RFID technology and its application

- Page 96:

RFID technology and its application

- Page 100:

RFID technology and its application

- Page 104:

RFID technology and its application

- Page 108:

RFID technology and its application

- Page 112:

RFID technology and its application

- Page 116:

3 RFID tag performance optimization

- Page 120:

RFID tag performance optimization:

- Page 124:

RFID tag performance optimization:

- Page 128:

RFID tag performance optimization:

- Page 132:

RFID tag performance optimization:

- Page 136:

(a) (b) 35 30 20 10 IE POWER-ON -RE

- Page 140:

RFID tag performance optimization:

- Page 144:

4 Resolution and integration of HF

- Page 148:

4.2.1 Far field 4.2.2 Near field Re

- Page 152:

Resolution and integration of HF an

- Page 156:

Resolution and integration of HF an

- Page 160:

Resolution and integration of HF an

- Page 164:

Resolution and integration of HF an

- Page 168:

Resolution and integration of HF an

- Page 172:

5 Integrating sensors and actuators

- Page 176:

Integrating sensors and actuators i

- Page 180:

Integrating sensors and actuators i

- Page 184:

Integrating sensors and actuators i

- Page 188:

Integrating sensors and actuators i

- Page 192:

Integrating sensors and actuators i

- Page 196:

Integrating sensors and actuators i

- Page 200:

Performance evaluation of WiFi RFID

- Page 204:

Performance evaluation of WiFi RFID

- Page 208:

Performance evaluation of WiFi RFID

- Page 212:

Performance evaluation of WiFi RFID

- Page 216:

Performance evaluation of WiFi RFID

- Page 220:

Performance evaluation of WiFi RFID

- Page 224:

7 Modeling supply chain network tra

- Page 228:

Modeling supply chain network traff

- Page 232:

Modeling supply chain network traff

- Page 236:

Modeling supply chain network traff

- Page 240:

Modeling supply chain network traff

- Page 244:

Modeling supply chain network traff

- Page 248:

Modeling supply chain network traff

- Page 252:

8 Deployment considerations for act

- Page 256:

Deployment considerations for activ

- Page 260: Deployment considerations for activ

- Page 264: Deployment considerations for activ

- Page 268: Deployment considerations for activ

- Page 272: Deployment considerations for activ

- Page 276: 9 RFID in the retail supply chain:

- Page 280: RFID in the retail supply chain: is

- Page 284: RFID in the retail supply chain: is

- Page 288: RFID in the retail supply chain: is

- Page 292: 10 Reducing barriers to ID system a

- Page 296: Reducing barriers to ID system adop

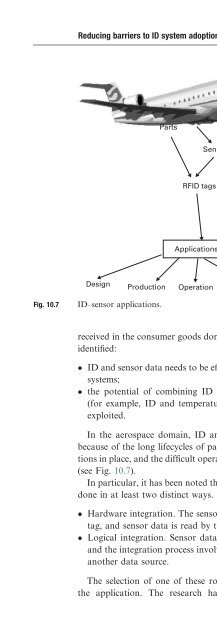

- Page 300: Reducing barriers to ID system adop

- Page 304: Reducing barriers to ID system adop

- Page 308: Reducing barriers to ID system adop

- Page 314: 132 Duncan McFarlane, Alan Thorne,

- Page 318: 134 Duncan McFarlane, Alan Thorne,

- Page 322: 136 Duncan McFarlane, Alan Thorne,

- Page 326: 138 Duncan McFarlane, Alan Thorne,

- Page 330: 140 Duncan McFarlane, Alan Thorne,

- Page 334: 142 Duncan McFarlane, Alan Thorne,

- Page 338: 11 The cold chain J. P. Emond The c

- Page 342: 146 J. P. Emond This explains why t

- Page 346: 148 J. P. Emond low limits) is enou

- Page 350: 150 J. P. Emond can interfere signi

- Page 354: 152 J. P. Emond let radio signals p

- Page 358: 154 J. P. Emond Fig. 11.4 Effects o

- Page 362:

156 J. P. Emond [19] Alain, L., La

- Page 366:

158 Thorsten Staake, Florian Michah

- Page 370:

160 Thorsten Staake, Florian Michah

- Page 374:

162 Thorsten Staake, Florian Michah

- Page 378:

164 Thorsten Staake, Florian Michah

- Page 382:

166 Thorsten Staake, Florian Michah

- Page 386:

168 Thorsten Staake, Florian Michah

- Page 390:

170 Dimitris Kiritsis, Hong-Bae Jun

- Page 394:

172 Dimitris Kiritsis, Hong-Bae Jun

- Page 398:

174 Dimitris Kiritsis, Hong-Bae Jun

- Page 402:

176 Dimitris Kiritsis, Hong-Bae Jun

- Page 406:

178 Dimitris Kiritsis, Hong-Bae Jun

- Page 410:

180 Dimitris Kiritsis, Hong-Bae Jun

- Page 414:

182 Dimitris Kiritsis, Hong-Bae Jun

- Page 418:

184 Bernd Scholz-Reiter, Dieter Uck

- Page 422:

186 Bernd Scholz-Reiter, Dieter Uck

- Page 426:

188 Bernd Scholz-Reiter, Dieter Uck

- Page 430:

190 Bernd Scholz-Reiter, Dieter Uck

- Page 434:

192 Bernd Scholz-Reiter, Dieter Uck

- Page 438:

194 Bernd Scholz-Reiter, Dieter Uck

- Page 442:

196 Bernd Scholz-Reiter, Dieter Uck

- Page 446:

15 Conclusions Stephen Miles, Sanja

- Page 450:

200 Stephen Miles, Sanjay Sarma, an

- Page 454:

202 Stephen Miles, Sanjay Sarma, an

- Page 458:

204 Stephen Miles, Sanjay Sarma, an

- Page 462:

206 Stephen Miles, Sanjay Sarma, an

- Page 466:

208 Stephen Miles, Sanjay Sarma, an

- Page 470:

210 Stephen Miles, Sanjay Sarma, an

- Page 474:

212 Stephen Miles, Sanjay Sarma, an

- Page 478:

214 Appendix EPCglobal certified te

- Page 482:

216 Editor biographies Sarma receiv

- Page 486:

218 Index location tracking, xvi, 9