ROTARY AND HANDLING TOOLS - National Oilwell Varco

ROTARY AND HANDLING TOOLS - National Oilwell Varco

ROTARY AND HANDLING TOOLS - National Oilwell Varco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CASING RUNNING <strong>TOOLS</strong><br />

100<br />

CRT350 & CRT500-14 & 20 CASING RUNNING TOOL<br />

The CRT introduces step change in the way casing is run today.<br />

By combining the functionality of field proven tools such as the Top<br />

Drive, Flush Mounted Spider (FMS), Fill and Circulation Tool and<br />

Hydraulic Single Joint Elevator (H-SJH & UX), casing operations are<br />

now safer, faster and more efficient. The CRT, which is connected<br />

directly to the Top Drive main shaft, hoists and lowers casing,<br />

spins in and makes up the casing connection. Additionally, while<br />

reciprocating and rotating the casing string, the CRT has the ability<br />

to fill-up and circulate.<br />

Safety<br />

•<br />

•<br />

Eliminates stabbing-board operations (leading contributor to<br />

LTA's while running casing), less manual handling in the V-door<br />

and fewer safety hazards.<br />

Power casing tong operations and work platforms have been<br />

removed, allowing for better ergonomics and work space<br />

around the well center.<br />

Economics<br />

•<br />

Drilling contractors or a reduced casing crew can run the<br />

casing, minimizing stand-by costs associated with weather or<br />

problematic well conditions.<br />

• The CRT integral compensator substantially reduces the risk of<br />

damage due to cross-threading.<br />

• Utilizing the Top Drive to control make-up reduces thread<br />

damage during the complete make-up cycle.<br />

Well Improvements<br />

•<br />

Assures that the casing can be set to the casing point with<br />

the ability of the CRT to push casing to bottom, fill, circulate,<br />

rotate, and reciprocate.<br />

• Reduces the risk of differential wall sticking.<br />

• Ability to pressure test.<br />

Efficiency<br />

•<br />

Less equipment to rig up; the CRT contains the single joint<br />

elevator, rigid link hoist and stabbing assembly, fill and<br />

circulation tool, and compensator in one assembly.<br />

• Single load-path design eliminates links.<br />

• The operator determines and controls the running/tripping<br />

speed, spin-in and make-up torques.<br />

• When running mixed strings, size of components can be<br />

changed within minutes through the twist lock design.<br />

Features CRT Compensator<br />

• Employs a patented cushioned weight compensator which<br />

balances out the weight of CRT.<br />

• Soft stabbing and thread compensation minimizes casing<br />

thread damage.<br />

CRT Pipe Sensor<br />

•<br />

The Pipe sensor detects the casing coupling so slips will<br />

set automatically at the correct position, ensuring casing<br />

connection integrity.<br />

• Provides feedback to CRT operator that the correct CRT<br />

stabbing height is reached.<br />

CRT Fill-up and Circulation Tool<br />

• Fill-up tool enables fast change out of seal and guide elements<br />

when mixed strings are run.<br />

• Prevents possible spills of expensive fluids.<br />

• Reduces the risk of environmental incidents.<br />

Single Joint Elevators<br />

• Hydraulic operated SJ-elevator (H-SJH & UX)<br />

• Hydraulic cylinder assembly to tilt the H-SJH elevator to the<br />

V-door.<br />

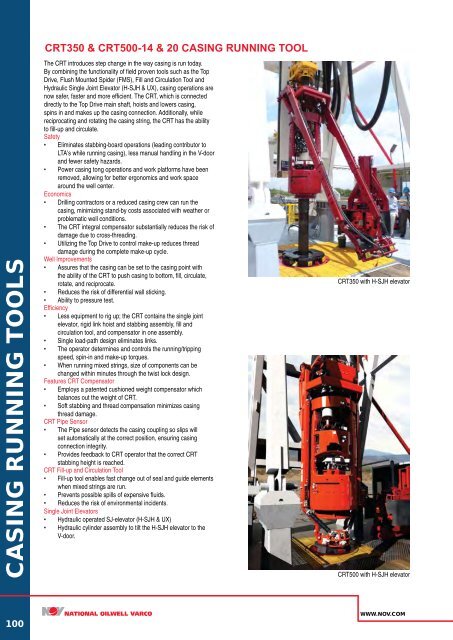

CRT350 with H-SJH elevator<br />

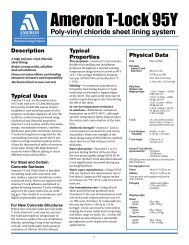

CRT500 with H-SJH elevator<br />

WWW.NOV.COM