InLine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

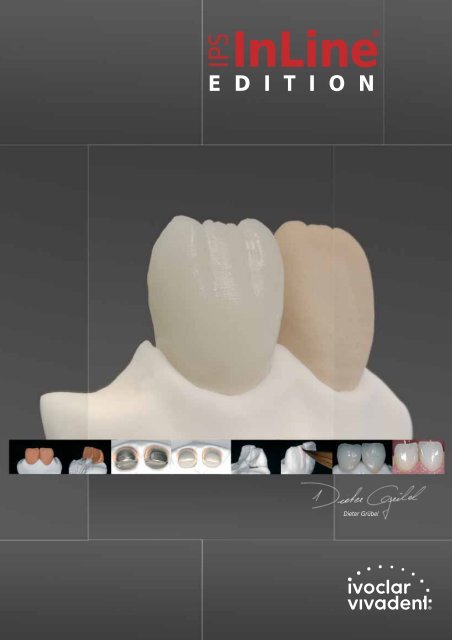

IPS<br />

<strong>InLine</strong><br />

®<br />

E D I T I O N<br />

Dieter Grübel

IPS<br />

<strong>InLine</strong><br />

®<br />

Dieter Grübel<br />

Ivoclar Vivadent Trainer, Liechtenstein

IMPRESSIVELY ”IN” –<br />

THE NEW LEUCITE METAL-CERAMIC<br />

There are innumerable ceramic assortments available on the market. New materials are consistently<br />

being offered. If you are satisfied with a veneering ceramic, you might ask yourself: why something<br />

new again?<br />

Every dental technician gains experience with different ceramic assortments during his professional<br />

life – either by interest or related to the material. However, already at the first attempt to try the<br />

new material, you realize that the result does not resemble that which is usually achieved with the<br />

familiar ceramic. The logical consequence: You have to adjust your processing technique to the new<br />

ceramic. But you don’t really have time for that!<br />

Often, it is advisable to have a closer look at the new product. In this IPS <strong>InLine</strong> Edition I try to<br />

show you what is important before you start with a new veneering ceramic and how you can<br />

efficiently and economically achieve a reproducible result.<br />

My experience:<br />

ACCURATE, FAST AND BEAUTIFUL<br />

THE NEW<br />

IPS<br />

<strong>InLine</strong><br />

®<br />

LEUCITE METAL-CERAMIC<br />

Most dental technicians will find the same factors as being important when veneering metal-ceramic restorations.<br />

For me, these factors are primarily shade stability – even after several firing cycles – optimized shrinkage<br />

behaviour, as well as fast processing and outstanding aesthetic properties. Exactly these aspects were<br />

considered in the development of IPS <strong>InLine</strong>.<br />

Shade<br />

The new shading of the ceramic enables the easy reproduction of the desired shade without shade loss, even<br />

at high firing temperatures and after multiple firing cycles.<br />

Shrinkage<br />

Due to the optimized sintering behaviour of the ceramic, every restoration, no matter if small or large, can<br />

be efficiently fabricated without complex add-on firings.<br />

Processing<br />

Thanks to the manifold improvements, such as the paste opaquer, which is available in ready-to-use jars or<br />

syringes, or the fluorescence opaquer, restorations can be fabricated faster and in a more controlled fashion.<br />

3

THE METAL FRAMEWORK – the foundation of eve<br />

Compatibility of alloys<br />

In order to meet the expectations of customers, it is<br />

important to me to process a ceramic that is insensitive and<br />

that can be processed and used on many different alloys.<br />

According to my experience, IPS <strong>InLine</strong> can be used on highgold,<br />

palladium-based or even base metal alloys without any<br />

problems – also with multiple firing cycles!<br />

Framework design<br />

The metal framework forms the basis for efficient working. The framework determines the<br />

success or failure of the metal-ceramic. Clinical long-term success requires good accuracy of<br />

fit, which in turn provides stability.<br />

IPS <strong>InLine</strong> is coordinated with a variety of Ivoclar Vivadent alloys in the CTE range of<br />

13.8–15.0 10 -6 K -1 25–500 °C.<br />

“The framework should be designed as small as possible in order to have as much<br />

space as possible available for the highly aesthetic veneer ..."<br />

That’s where the problems start with which we have to deal in the daily working routine:<br />

– Tension cracks<br />

– Strength<br />

– Shrinkage<br />

– Aesthetics<br />

Sources of error which have to be compensated by the veneering ceramic are very timeconsuming<br />

and have a big influence on the quality of the completed restoration.<br />

My experiences/rule of thumb:<br />

High-gold alloy min. 0.5 mm<br />

Base metal alloy min. 0.3 mm<br />

2.0 mm<br />

1.7 mm<br />

1.2 mm<br />

1.5 mm 1.5 mm<br />

0.9 mm<br />

>_ 1.2 mm<br />

>_ 1.2 mm<br />

Preparation guidelines Layering diagram Framework design Completed metal framework<br />

TIP:<br />

Independent of the size of the tooth:<br />

Always try to achieve a consistent layer thickness of the framework to be veneered.<br />

4

y metal-ceramic restoration<br />

Surface finishing<br />

When the criteria for framework design and framework thickness have been<br />

considered, the alloy surface is finished. It should be a matter of course to<br />

observe certain basic rules for finishing. In addition to the type of finishers<br />

used, the appropriate application is of utmost importance.<br />

TIP:<br />

Always use the same set of grinding instruments for the<br />

respective alloy. If different instruments are used, foreign<br />

objects will be included into the alloy surface, which may<br />

result in bubbles or cracks in the ceramic.<br />

An impeccable surface is achieved by using a white oxide stone for grinding.<br />

5

HOW DO I PROPERLY HANDLE MY ALLOY?<br />

Oxide firing – quality control of the metal framework<br />

The last important working step before the opaquer is applied is the thermal treatment<br />

(oxide firing), which has to be done in different ways depending on the alloy.<br />

Different manufacturing methods<br />

When it comes to oxide firing, there is a great confusion/uncertainty. Is oxide firing required<br />

at all? If yes, which parameters have to be applied? This confusion can certainly be related to<br />

the fact that there are different recommendations for the various types of alloys.<br />

Below are some examples as provided from dental technicians to dental technicians, without<br />

any reference to a specific alloy or manufacturer.<br />

• Sandblast – apply opaquer<br />

• Sandblast – oxidize – apply opaquer<br />

• Sandblast – oxidize – sandblast – apply opaquer<br />

• Oxidize – with/without vacuum<br />

• Oxidize – with/without holding time<br />

• No oxide firing required<br />

• Sandblast – oxidize – pickle – apply opaquer • Oxidize at 925 °C, 950 °C, 1010 °C<br />

TIP:<br />

Since there are no universal working procedures and oxide firing temperatures,<br />

please observe the respective Instructions for Use of the manufacturer. If no<br />

Instructions for Use are enclosed, you should keep your hands off this alloy.<br />

Bond between alloy and veneering<br />

material<br />

The oxide layer forms the most important component of the<br />

bond between metal and ceramic. Therefore, particular<br />

attention should be paid to this working step.<br />

~70 % bond by diffusion (OXIDE LAYER)<br />

~15 % bond by compression<br />

Metal<br />

Oxygen<br />

Silica<br />

~15 % mechanical bond<br />

6<br />

Graphic representation of the chemical bond. The alloy and ceramic “share”<br />

oxygen atoms, which generate the adhesive bond.<br />

[Schnettger A., Fachhochschule Osnabrück 2004]

Cleanness of the surface<br />

The oxide firing provides information on the cleanness of the surface and thus offers a<br />

control whether the metal framework is free of gases or contamination. The oxide must be<br />

even and clean. If the colour is not consistent, the procedure has to be repeated.<br />

Presoldering<br />

With presoldering in particular, it is important<br />

to check the cleanness of the metal framework<br />

with oxide firing.<br />

After oxide firing<br />

Pickling<br />

with PCT AScid<br />

Cleaning<br />

with steam<br />

IPS d.SIGN 98<br />

high-gold alloy<br />

IPS d.SIGN 96<br />

gold-reduced alloy<br />

Pickling<br />

Pickling of the oxide layer with PCT AScid is recommended for high-gold alloys with a zinc or<br />

copper content to ensure a sound metal-ceramic bond.<br />

– Processing<br />

Place the alloy into the PCT AScid solution for 5–10 minutes. Rinse pickled<br />

objects with water and clean with steam. PCT AScid will reliably remove oxides<br />

and flux residue.<br />

(Contraindicated for base metal alloys)<br />

7

ADVANTAGES OF THE IPS INLINE OPAQUER<br />

The IPS <strong>InLine</strong> Opaquer is characterized by its optimum consistency. Therefore, the opaquer is<br />

ready to use without the need to mix it. This will considerably facilitate your daily working<br />

routine. Due to the ideal consistency of the opaquer, you will always achieve the same<br />

masking effect.<br />

Ideal consistency, no individual mixing required.<br />

1 st wash firing (930 °C) 2 nd opaquer firing (930 °C)<br />

Apply a very thin layer of opaquer to ensure a sound bond<br />

between ceramics and metal. Gases that have not escaped<br />

during oxide firing can be eliminated during wash firing.<br />

The second opaquer layer is used to mask the metal framework<br />

and reproduce the shade of the natural tooth.<br />

Optimum masking effect<br />

Enhanced fluorescence with in-depth<br />

effect – Opaquer F<br />

Either apply the Opaquer F as a thin, third opaquer layer and<br />

fire or mix up to 20% of Opaquer F with the conventional<br />

IPS <strong>InLine</strong> Opaquers before the second layer is applied.<br />

8

WHAT ARE THE PROPERTIES OF DENTIN?<br />

The brightness value of the dentin is decisive for the final result of the restoration. In virtually<br />

all the shade ranges, the dentin has to feature a high brightness value. The opaquer supports<br />

the dentin, which is, however, not always sufficient.<br />

Depending on the ceramic type and properties, the dental technician has to process the<br />

Dentin material in different ways to achieve his goal. Based on this example, I like to show<br />

how different ceramic systems can be.<br />

IPS Classic IPS <strong>InLine</strong> IPS d.SIGN IPS Classic IPS <strong>InLine</strong> IPS d.SIGN<br />

Feldspar ceramics<br />

Low colour saturation<br />

High brightness value<br />

IPS Classic – high translucency, low colour saturation, high brightness value<br />

You have to focus on the dentin shade in particular. The ceramic has a very low colour saturation and may lose a lot of colour with multiple firing<br />

cycles. This is particularly the case with high-fusing ceramic materials, such as feldspar and leucite. The colour and chroma have to be compensated<br />

by Intensive Dentin or Deep Dentin materials.<br />

IPS Classic IPS <strong>InLine</strong> IPS d.SIGN IPS Classic IPS <strong>InLine</strong> IPS d.SIGN<br />

Leucite metal-ceramics<br />

High colour saturation<br />

Mean brightness value<br />

IPS <strong>InLine</strong> – high translucency, high colour saturation, mean brightness value<br />

The brightness value has to be mastered, as high translucency and high colour saturation result in a low brightness value. This is easily achieved<br />

using Deep Dentin materials.<br />

Fluorapatite leucite glass-ceramic<br />

IPS Classic IPS <strong>InLine</strong> IPS d.SIGN IPS Classic IPS <strong>InLine</strong> IPS d.SIGN<br />

High colour saturation<br />

IPS d.SIGN – mean translucency, high colour saturation, high brightness value<br />

The fluorapatite crystals have a very lifelike light scattering/light reflection. Hence, highly aesthetic results can be easily achieved.<br />

High brightness value<br />

9

THE DENTIN CORE<br />

The most important and thus most difficult thing for me was to always have control over the<br />

dentin. Factors, such as shade, chroma, brightness and translucency have to be contained<br />

already in the dentin core. With the first dentin firing, these properties become visible.<br />

The dimensions of the dentin core<br />

All these properties (shade, chroma, brightness and translucency) have to be ideally adjusted<br />

in size and volume to the natural tooth.<br />

• If the dentin core is too SMALL, I automatically apply too much Impulse and Incisal materials<br />

and the tooth shade, brightness etc. will be lost.<br />

• If the dentin core is too LARGE, there is no space for the Impulse and Incisal materials<br />

and the tooth will lose its aesthetic properties.<br />

TIP:<br />

The biggest advantage of firing the dentin core is that we can efficiently and<br />

elegantly control the dimensions of the dentin core by individual grinding.<br />

A lifelike surface texture is created by individual grinding.<br />

TPP: The incisal edge has to be reduced wafer-thin to achieve a harmonious tapering of the dentin core.<br />

Predictable results<br />

If required, small adjustments of shade, chroma and brightness can be made using Impulse<br />

and Incisal materials in the second firing cycle.<br />

10

Design of the dentin core<br />

Fully anatomical build-up of Deep Dentin and Dentin<br />

The two ceramic materials are always used to fabricate a fully anatomical build-up. Thus, we<br />

can achieve consistent shade, chroma, brightness and translucency in the tooth.<br />

TIP:<br />

This recommendation may also be applied to other<br />

ceramics. Depending on the properties of the ceramic,<br />

the dimensions will differ.<br />

The translucency of the incisal edge can be ideally controlled by individual grinding of the dentin core. The incisal edge is tapered until the desired translucency is<br />

achieved.<br />

Big advantage: predictable results. I can see the result even before I start to cover the dentin core with Impulse and Incisal materials.<br />

Young tooth / Translucent<br />

Young tooth / Opaque<br />

Incisal<br />

Dentin<br />

Incisal<br />

Dentin<br />

Deep Dentin<br />

Deep Dentin<br />

With high brightness and high translucency, 1 /3 of the tooth volume<br />

is built up with Deep Dentin.<br />

With high brightness and low translucency, 2 /3 of the tooth volume is<br />

built up with Deep Dentin.<br />

11

VENEERING<br />

1 st firing<br />

1. Line the dentin with two thirds Deep Dentin to control the translucency and entirely cover<br />

the opaquer.<br />

2. Subsequently, complete the tooth with Dentin materials to the natural size of the adjacent<br />

tooth.<br />

2 nd firing<br />

Cover the entire tooth using the respective Incisal materials. In the present case, I mixed<br />

Transpa Incisal TI1 with 40% Opal Effect 2 in order to increase the opacity and brightness.<br />

My goal was to create a very young tooth with low translucency, high opacity, and a high<br />

brightness value.<br />

The incisal edge is covered with Opal Effect 1 to achieve a nice opal effect.<br />

Mix Transpa Incisal TI1 with 40% Opal Effect 2 and apply.<br />

TIP:<br />

Always place the ceramic in the same moist condition<br />

into the ceramic furnace. This will optimize the<br />

firing quality and shade of the ceramic compared to<br />

a ceramic that is placed in a dry condition into the<br />

furnace.<br />

Completed restoration<br />

12

AESTHETIC RESULTS<br />

Young tooth with<br />

high translucency<br />

Young tooth with<br />

high translucency<br />

and mamelon structure<br />

Deep Dentin and Dentin firing<br />

If an individual design is established by grinding, the translucency in the incisal edge can<br />

be controlled. If required, a slight mamelon structure can be designed.<br />

The dentin core is reduced and ends about 0.5 mm before the incisal edge.<br />

The dentin core is reduced to a mamelon structure and ends about 0.5 mm before the incisal edge.<br />

The incisal edge is built up to full contour with Opal Effect E1 material. Dentin material is applied to the mamelon structure. Subsequently, the area is covered with Incisal TI1.<br />

13

THOROUGH PREPARATION<br />

If you want to achieve your working goal quickly and efficiently, you have to invest a lot of<br />

time in thorough planning. In implantology in particular or with large restorations, it may<br />

have severe consequences for the final result if the preparation is not well thought-out. If<br />

errors occur during the working process, this will considerably influence the quality of and<br />

the time required for the fabrication of the restoration.<br />

• Study model<br />

A study model is of utmost<br />

importance in order to<br />

adjust the work individually<br />

to the case and situation.<br />

• Guidelines provided by the silicone matrix<br />

The silicone matrix helps to control the shape of the metal framework.<br />

• Study model / fully anatomical wax-up<br />

The anatomy (marginal ridge) can be controlled with the help of the fully<br />

anatomical study model. This will support the layering process and<br />

subsequent grinding procedure.<br />

• Guidelines provided by the silicone matrix<br />

The size of the restoration may be ideally adjusted with the silicone matrix.<br />

Consequently, the tooth can be ideally copied.<br />

14

THE CERAMIC SHOULDER …<br />

... has become the standard in many<br />

laboratories<br />

The ceramic shoulder should be a standard if predominantly<br />

base metals are used. Hence, problems such as gingival<br />

recession or visible black margins can be prevented.<br />

Margin A2<br />

Intensive Margin<br />

Opaque<br />

If limited space is available, it is recommended to cover the translucency of the Margin materials with a<br />

thin layer of Intensive Margin Opaque to completely mask the metal framework.<br />

Impressive results with the IPS <strong>InLine</strong> materials regarding accuracy of fit and shade brilliance.<br />

Firing Brennen parameters im Programat Ofen: T B<br />

Brennparameter 1. + 2. Margin °C Brand °C<br />

S<br />

Min.<br />

➚<br />

t<br />

°C/Min.<br />

H<br />

Min.<br />

V1<br />

°C<br />

V2<br />

°C<br />

1 st and 2 nd T Margin B firing S<br />

➚<br />

930 t<br />

H403<br />

V 1<br />

4<br />

V 2<br />

60<br />

1<br />

450<br />

929<br />

930°C 403°C<br />

Margin Add-On firing<br />

4 Min.<br />

60°C<br />

900<br />

1 Min.<br />

403<br />

450°C<br />

929°C<br />

4<br />

60<br />

1<br />

450<br />

899<br />

15

FIRST DENTIN FIRING<br />

For the first dentin firing, the dentin is built up to its original size. The shrinkage of the first<br />

firing provides the space required for the Impulse and Incisal materials.<br />

Fully anatomical build-up with Deep Dentin up to about 60% of the<br />

entire volume of the natural tooth.<br />

Subsequently, the Deep Dentin areas are covered with Dentin<br />

material and built up to full size.<br />

Fully anatomical build-up with Dentin material. Cut-back in the incisal third down to the opaquer. Deep Dentin material is thinly tapered towards the incisal edge and<br />

subsequently covered with Dentin material.<br />

Firing parameters<br />

T<br />

°C<br />

B<br />

°C<br />

S<br />

Min.<br />

➚<br />

t<br />

°C/Min.<br />

H<br />

Min.<br />

V1<br />

°C<br />

V2<br />

°C<br />

1 st Dentin/Incisal firing<br />

910<br />

403<br />

4<br />

60<br />

1<br />

450<br />

909<br />

16

SECOND IMPULSE AND INCISAL FIRING<br />

First, the palatal area is built up to full contour with Incisal material. Advantage: definition of the incisal edge. Dentin and Impulse materials can be selectively applied.<br />

Applied Impulse materials (E1, E3, Transpa blue, Occlusal Dentin<br />

brown).<br />

Finally, the tooth is completed using Incisal materials.<br />

Firing parameters<br />

T<br />

°C<br />

B<br />

°C<br />

S<br />

Min.<br />

➚<br />

t<br />

°C/Min.<br />

H<br />

Min.<br />

V1<br />

°C<br />

V2<br />

°C<br />

2 nd Dentin/Incisal firing<br />

900<br />

403<br />

4<br />

60<br />

1<br />

450<br />

899<br />

17

AESTHETICS AND EXCELLENCE<br />

Shape and texture<br />

If you try to achieve aesthetic restorations by using a lot of Impulse materials and special<br />

layering techniques, you will often be disappointed by the result. I have come to realize that<br />

the search for impeccable shade matching and the attempt to ideally copy every internal<br />

effect or defect, can only be an approximation. However, this imitation becomes more and<br />

more easy with continuously improving ceramic assortments.<br />

The shape and tooth surface form the basis for success. Those who succeed in establishing<br />

the basis will also achieve what is known as the chameleon effect and thus impeccable<br />

integration of the restoration into the natural surroundings.<br />

Silver powder is used to analyze and control the shape and surface structure. I apply silver<br />

powder both on the natural tooth and the restoration. This will show possible errors, which<br />

can be selectively adjusted.<br />

Even the smallest errors become apparent with silver powder.<br />

18

NATURAL ENAMEL CRACK<br />

I use the conventional Dentin materials to achieve a natural enamel crack. The Stains are very<br />

intensive and difficult to control. To achieve a better contrast during application, I colour the<br />

Dentin material.<br />

Incisal material is applied up to the area where an<br />

enamel crack is desired.<br />

The Incisal material is carefully covered with the coloured Dentin<br />

material.<br />

Important: The ceramic material should be equally moist to<br />

ensure proper application (mixing with glaze liquid).<br />

Completed IPS <strong>InLine</strong> restoration<br />

Conclusion<br />

IPS <strong>InLine</strong> offers me the flexibility in processing which I need for my daily work. The<br />

easy handling properties and the lifelike aesthetics have convinced me to integrate<br />

IPS <strong>InLine</strong> into my daily working routine in the laboratory.<br />

Enjoy working with IPS <strong>InLine</strong>.<br />

Dieter Grübel<br />

Ivoclar Vivadent Trainer | Bendererstrasse 2 | FL-9494 Schaan | Principality of Liechtenstein<br />

19

603427/0906/e/RDV