recent advances in ginning for lowering cost and ... - Bajaj Group

recent advances in ginning for lowering cost and ... - Bajaj Group

recent advances in ginning for lowering cost and ... - Bajaj Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

(RECENT ADVANCES IN GINNING FOR LOWERING COST AND IMPROVING OF EFFICIENCY)<br />

# 2 #<br />

cottons hav<strong>in</strong>g length up to 27-28 mm. The s<strong>in</strong>gle roller g<strong>in</strong>s <strong>and</strong> double roller g<strong>in</strong>s can be used <strong>for</strong> cottons of<br />

all staple categories while Rotobar g<strong>in</strong> is used <strong>for</strong> long <strong>and</strong> extralong cottons particularly black seeds only.<br />

Among all the types of roller g<strong>in</strong>s, double roller g<strong>in</strong>s are most commonly used <strong>in</strong> India <strong>and</strong> other countries due<br />

to its advantages over other g<strong>in</strong>n<strong>in</strong>g technologies. The g<strong>in</strong>n<strong>in</strong>g operation needs to be carried out carefully so<br />

that the fibres are not damaged or broken dur<strong>in</strong>g the process <strong>and</strong> the overall quality of l<strong>in</strong>t rema<strong>in</strong>s practically<br />

unchanged. For ensur<strong>in</strong>g this, mach<strong>in</strong>ery used <strong>for</strong> the g<strong>in</strong>n<strong>in</strong>g process requires proper adjustments <strong>and</strong><br />

regular ma<strong>in</strong>tenance. The details of each g<strong>in</strong>n<strong>in</strong>g mach<strong>in</strong>e is elaborated below:<br />

Figure 3.1 Improved version of charkha g<strong>in</strong><br />

3.2 Saw G<strong>in</strong>s<br />

The Saw G<strong>in</strong> belongs to second-generation tool <strong>in</strong>vented by Eli Whitney <strong>in</strong> 1794, <strong>in</strong> the USA <strong>and</strong> the latest<br />

version is shown <strong>in</strong> Figure 3.2. It consists of a series of circular saws, 305 to 407 mm (12 to 18 <strong>in</strong>ches) <strong>in</strong><br />

diameter. All the saws are mounted closely on an axle <strong>and</strong> are made to revolve at high speed <strong>in</strong> order to tear<br />

the l<strong>in</strong>t away from a roll of seed cotton. The saw projects slightly between bars or ribs, which are so, spaced<br />

that they prevent the seed from go<strong>in</strong>g <strong>for</strong>ward. Fibres are thus torn away from the seeds with high speed. The<br />

seed cotton is fed cont<strong>in</strong>uously <strong>in</strong>to a rounded box or hopper. The action of the saws keeps it revolv<strong>in</strong>g <strong>in</strong> a<br />

loosely compacted roll. The seed falls through a grid <strong>in</strong>to a collect<strong>in</strong>g box or seed conveyor. The l<strong>in</strong>t is<br />

whipped off the teeth of the saws by high-speed brushes or an air blast.<br />

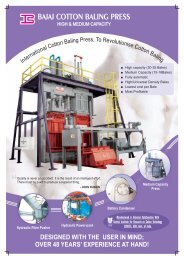

Figure 3.2 Saw G<strong>in</strong> st<strong>and</strong>s <strong>in</strong> g<strong>in</strong>nery <strong>in</strong> USA<br />

Contd. …3.