CASE STUDY: MARITIME TRANSPORT - Marine Technology

CASE STUDY: MARITIME TRANSPORT - Marine Technology

CASE STUDY: MARITIME TRANSPORT - Marine Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

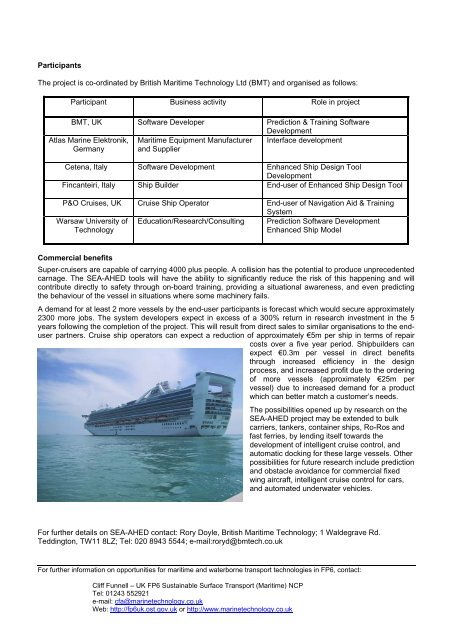

Participants<br />

The project is co-ordinated by British Maritime <strong>Technology</strong> Ltd (BMT) and organised as follows:<br />

Participant Business activity Role in project<br />

BMT, UK Software Developer Prediction & Training Software<br />

Development<br />

Atlas <strong>Marine</strong> Elektronik,<br />

Germany<br />

Maritime Equipment Manufacturer<br />

and Supplier<br />

Interface development<br />

Cetena, Italy Software Development Enhanced Ship Design Tool<br />

Development<br />

Fincanteiri, Italy Ship Builder End-user of Enhanced Ship Design Tool<br />

P&O Cruises, UK Cruise Ship Operator End-user of Navigation Aid & Training<br />

System<br />

Warsaw University of<br />

<strong>Technology</strong><br />

Education/Research/Consulting Prediction Software Development<br />

Enhanced Ship Model<br />

Commercial benefits<br />

Super-cruisers are capable of carrying 4000 plus people. A collision has the potential to produce unprecedented<br />

carnage. The SEA-AHED tools will have the ability to significantly reduce the risk of this happening and will<br />

contribute directly to safety through on-board training, providing a situational awareness, and even predicting<br />

the behaviour of the vessel in situations where some machinery fails.<br />

A demand for at least 2 more vessels by the end-user participants is forecast which would secure approximately<br />

2300 more jobs. The system developers expect in excess of a 300% return in research investment in the 5<br />

years following the completion of the project. This will result from direct sales to similar organisations to the enduser<br />

partners. Cruise ship operators can expect a reduction of approximately €5m per ship in terms of repair<br />

costs over a five year period. Shipbuilders can<br />

expect €0.3m per vessel in direct benefits<br />

through increased efficiency in the design<br />

process, and increased profit due to the ordering<br />

of more vessels (approximately €25m per<br />

vessel) due to increased demand for a product<br />

which can better match a customer’s needs.<br />

The possibilities opened up by research on the<br />

SEA-AHED project may be extended to bulk<br />

carriers, tankers, container ships, Ro-Ros and<br />

fast ferries, by lending itself towards the<br />

development of intelligent cruise control, and<br />

automatic docking for these large vessels. Other<br />

possibilities for future research include prediction<br />

and obstacle avoidance for commercial fixed<br />

wing aircraft, intelligent cruise control for cars,<br />

and automated underwater vehicles.<br />

For further details on SEA-AHED contact: Rory Doyle, British Maritime <strong>Technology</strong>; 1 Waldegrave Rd.<br />

Teddington, TW11 8LZ; Tel: 020 8943 5544; e-mail:roryd@bmtech.co.uk<br />

For further information on opportunities for maritime and waterborne transport technologies in FP6, contact:<br />

Cliff Funnell – UK FP6 Sustainable Surface Transport (Maritime) NCP<br />

Tel: 01243 552921<br />

e-mail: cfa@marinetechnology.co.uk<br />

Web: http://fp6uk.ost.gov.uk or http://www.marinetechnology.co.uk