Cell Culture & Upstream Processing - IBC Life Sciences

Cell Culture & Upstream Processing - IBC Life Sciences

Cell Culture & Upstream Processing - IBC Life Sciences

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

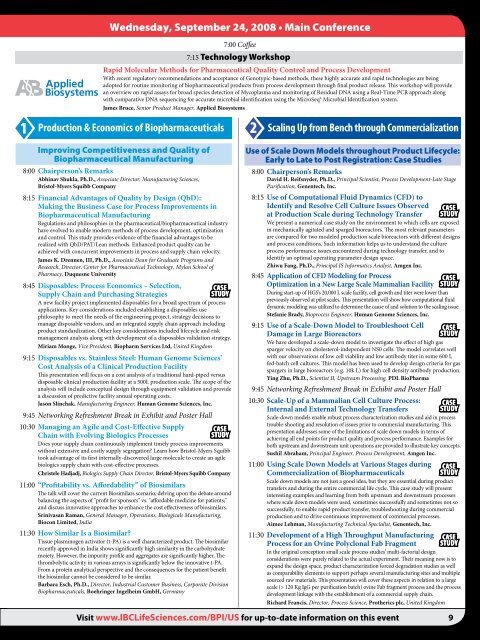

Wednesday, September 24, 2008 • Main Conference<br />

Improving Competitiveness and Quality of<br />

Biopharmaceutical Manufacturing<br />

8:00 Chairperson’s Remarks<br />

Abhinav Shukla, Ph.D., Associate Director, Manufacturing <strong>Sciences</strong>,<br />

Bristol-Myers Squibb Company<br />

8:15 Financial Advantages of Quality by Design (QbD):<br />

Making the Business Case for Process Improvements in<br />

Biopharmaceutical Manufacturing<br />

Regulations and philosophies in the pharmaceutical/biopharmaceutical industry<br />

have evolved to enable modern methods of process development, optimization<br />

and control. This study provides evidence of the financial advantages to be<br />

realized with QbD/PAT/Lean methods. Enhanced product quality can be<br />

achieved with concurrent improvements in process and supply chain velocity.<br />

James K. Drennen, III, Ph.D., Associate Dean for Graduate Programs and<br />

Research, Director, Center for Pharmaceutical Technology, Mylan School of<br />

Pharmacy, Duquesne University<br />

8:45 Disposables: Process Economics – Selection,<br />

Supply Chain and Purchasing Strategies<br />

CASE<br />

STUDY<br />

A new facility project implemented disposables for a broad spectrum of process<br />

applications. Key considerations included establishing a disposables use<br />

philosophy to meet the needs of the engineering project, strategy decisions to<br />

manage disposable vendors, and an integrated supply chain approach including<br />

product standardization. Other key considerations included lifecycle and risk<br />

management analysis along with development of a disposables validation strategy.<br />

Miriam Monge, Vice President, Biopharm Services Ltd, United Kingdom<br />

9:15 Disposables vs. Stainless Steel: Human Genome <strong>Sciences</strong>’<br />

Cost Analysis of a Clinical Production Facility<br />

This presentation will focus on a cost analysis of a traditional hard-piped versus<br />

disposable clinical production facility at a 500L production scale. The scope of the<br />

analysis will include conceptual design through equipment validation and provide<br />

a discussion of predictive facility annual operating costs.<br />

Jason Slinchak, Manufacturing Engineer, Human Genome <strong>Sciences</strong>, Inc.<br />

9:45 Networking Refreshment Break in Exhibit and Poster Hall<br />

10:30 Managing an Agile and Cost-Effective Supply<br />

Chain with Evolving Biologics Processes<br />

CASE<br />

STUDY<br />

Does your supply chain continuously implement timely process improvements<br />

without extensive and costly supply segregation? Learn how Bristol-Myers Squibb<br />

took advantage of its first internally-discovered large molecule to create an agile<br />

biologics supply chain with cost-effective processes.<br />

Christele Hadjadj, Biologics Supply Chain Director, Bristol-Myers Squibb Company<br />

11:00 “Profitability vs. Affordability” of Biosimilars<br />

The talk will cover the current Biosimilars scenario, delving upon the debate around<br />

balancing the aspects of "profit for sponsors" vs. "affordable medicine for patients;"<br />

and discuss innovative approaches to enhance the cost effectiveness of biosimilars.<br />

Srinivasan Raman, General Manager, Operations, Biologicals Manufacturing,<br />

Biocon Limited, India<br />

11:30 How Similar Is a Biosimilar?<br />

Tissue plasminogen activator (t-PA) is a well characterized product. The biosimilar<br />

recently approved in India shows significantly high similarity in the carbohydrate<br />

moiety. However, the impurity profile and aggregates are significantly higher. The<br />

thrombolytic activity in various arrays is significantly below the innovative t-PA.<br />

From a protein analytical perspective and the consequences for the patient benefit<br />

the biosimilar cannot be considered to be similar.<br />

Barbara Esch, Ph.D., Director, Industrial Customer Business, Corporate Division<br />

Biopharmaceuticals, Boehringer Ingelheim GmbH, Germany<br />

7:00 Coffee<br />

7:15 Technology Workshop<br />

Rapid Molecular Methods for Pharmaceutical Quality Control and Process Development<br />

With recent regulatory recommendations and acceptance of Genotypic-based methods, these highly accurate and rapid technologies are being<br />

adopted for routine monitoring of biopharmaceutical products from process development through final product release. This workshop will provide<br />

an overview on rapid assays for broad species detection of Mycoplasma and monitoring of Residual DNA using a Real-Time PCR approach along<br />

with comparative DNA sequencing for accurate microbial identification using the MicroSeq® Microbial Identification system.<br />

James Bruce, Senior Product Manager, Applied Biosystems<br />

1 Production & Economics of Biopharmaceuticals 2 Scaling Up from Bench through Commercialization<br />

Use of Scale Down Models throughout Product <strong>Life</strong>cycle:<br />

Early to Late to Post Registration: Case Studies<br />

8:00 Chairperson’s Remarks<br />

David H. Reifsnyder, Ph.D., Principal Scientist, Process Development-Late Stage<br />

Purification, Genentech, Inc.<br />

8:15 Use of Computational Fluid Dynamics (CFD) to<br />

Identify and Resolve <strong>Cell</strong> <strong>Culture</strong> Issues Observed<br />

at Production Scale during Technology Transfer<br />

CASE<br />

STUDY<br />

We present a numerical case study on the environment to which cells are exposed<br />

in mechanically agitated and sparged bioreactors. The most relevant parameters<br />

are compared for two modeled production scale bioreactors with different designs<br />

and process conditions. Such information helps us to understand the culture<br />

process performance issues encountered during technology transfer, and to<br />

identify an optimal operating parameter design space.<br />

Zhiwu Fang, Ph.D., Principal IS Informatics Analyst, Amgen Inc.<br />

8:45 Application of CFD Modeling for Process<br />

Optimization in a New Large Scale Mammalian Facility<br />

CASE<br />

STUDY<br />

During start-up of HGS’s 20,000 L scale facility, cell growth and titer were lower than<br />

previously observed at pilot scales. This presentation will show how computational fluid<br />

dynamic modeling was utilized to determine the cause of and solution to the scaling issue.<br />

Stefanie Brady, Bioprocess Engineer, Human Genome <strong>Sciences</strong>, Inc.<br />

9:15 Use of a Scale-Down Model to Troubleshoot <strong>Cell</strong><br />

Damage in Large Bioreactors<br />

CASE<br />

STUDY<br />

We have developed a scale-down model to investigate the effect of high gas<br />

sparger velocity on cholesterol-independent NS0 cells. The model correlates well<br />

with our observations of low cell viability and low antibody titer in some 600 L<br />

fed-batch cell cultures. This model has been used to develop design criteria for gas<br />

spargers in large bioreactors (e.g. 10k L) for high cell density antibody production.<br />

Ying Zhu, Ph.D., Scientist II, <strong>Upstream</strong> <strong>Processing</strong>, PDL BioPharma<br />

9:45 Networking Refreshment Break in Exhibit and Poster Hall<br />

10:30 Scale-Up of a Mammalian <strong>Cell</strong> <strong>Culture</strong> Process:<br />

Internal and External Technology Transfers<br />

CASE<br />

STUDY<br />

Scale-down models enable robust process characterization studies and aid in process<br />

trouble-shooting and resolution of issues prior to commercial manufacturing. This<br />

presentation addresses some of the limitations of scale down models in terms of<br />

achieving all end points for product quality and process performance. Examples for<br />

both upstream and downstream unit operations are provided to illustrate key concepts.<br />

Sushil Abraham, Principal Engineer, Process Development, Amgen Inc.<br />

11:00 Using Scale Down Models at Various Stages during<br />

Commercialization of Biopharmaceuticals<br />

CASE<br />

STUDY<br />

Scale down models are not just a good idea, but they are essential during product<br />

transfers and during the entire commercial life cycle. This case study will present<br />

interesting examples and learning from both upstream and downstream processes<br />

where scale down models were used, sometimes successfully and sometimes not so<br />

successfully, to enable rapid product transfer, troubleshooting during commercial<br />

production and to drive continuous improvement of commercial processes.<br />

Aimee Lehman, Manufacturing Technical Specialist, Genentech, Inc.<br />

11:30 Development of a High Throughput Manufacturing<br />

Process for an Ovine Polyclonal Fab Fragment<br />

CASE<br />

STUDY<br />

In the original conception small scale process studies’ multi-factorial design<br />

considerations were purely related to the actual experiment. Their meaning now is to<br />

expand the design space, product characterization forced degradation studies as well<br />

as comparability elements to support perhaps several manufacturing sites and multiple<br />

sourced raw materials. This presentation will cover these aspects in relation to a large<br />

scale (> 120 Kg IgG per purification batch) ovine Fab fragment process and the process<br />

development linkage with the establishment of a commercial supply chain.<br />

Richard Francis, Director, Process Science, Protherics plc, United Kingdom<br />

Visit www.<strong>IBC</strong><strong>Life</strong><strong>Sciences</strong>.com/BPI/US for up-to-date information on this event 9