Elastoseal EPDM Geomembrane References - Australian ...

Elastoseal EPDM Geomembrane References - Australian ...

Elastoseal EPDM Geomembrane References - Australian ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Elastoseal</strong> <strong>EPDM</strong> <strong>Geomembrane</strong> <strong>References</strong><br />

Public Company Coal Mines Kolubara, Lazarevac, Serbia<br />

Fabrication and installation of the Geomebrane<br />

Prefabricated panel sizes were determined by the location and<br />

cross section of the river banks. Layout drawings of each section<br />

were first made and approved so that each panel number<br />

is located in its precise location on the river section.<br />

For the river banks the size of the panels varied between 12 to<br />

15 m width by 50 to 67 m length. The length was determined<br />

by full canal section width so that only longitudinal cross channel<br />

seams were used. This allowed for full double fusion field<br />

seams an QC air channel testing across the new river section.<br />

The lake bank section required panels 20 to 35 m in width by<br />

50 m in length.<br />

The prime contractor scheduled incremental canal sections<br />

for preparation of earth works, lining installation and cover soil<br />

placement at a one week basis. Immediately after positioning<br />

the cross canal seams were made by dual track thermal fusion<br />

bonding with air channel for testing. All field seams were tested<br />

with air pressure direct after seaming. In addition all subgrade<br />

preparation, panel placement procedures, welding, testing and<br />

reporting was accomplished in accordance with SealEco QAS<br />

procedures and under full third party CQA observation.<br />

Construction Quality Control and Assurance<br />

The fully designed and implemented SealEco Quality Assurance<br />

System was made a part of the contract documents and<br />

utilized to the full extent on the Kolubara project. The QAS was<br />

comprehensive and included quality procedures from original<br />

roll goods manufacture through cover soil or aggregate placement.<br />

The QAS included the following:<br />

QC Manufacture of rollgods, QC Fabrication of panels,<br />

QC CCL Material and Placement, QC Subgrade Preparation,<br />

QC Panel Placement and Thermal Fusion Field Seaming and<br />

QC Cover Soils and Aggregate Placement.<br />

Implementation of the QAS in the field and at the fabrication<br />

plant was carried out by the third party consulting organisation<br />

CIP, Institute for Transportation, Belgrade.<br />

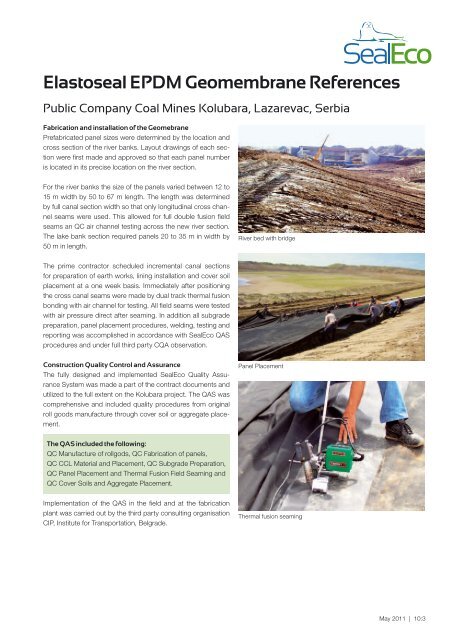

River bed with bridge<br />

Panel Placement<br />

Thermal fusion seaming<br />

May 2011 | 10:3