Detailed course plan (tentative) - Beyond Grey Pinstripes

Detailed course plan (tentative) - Beyond Grey Pinstripes

Detailed course plan (tentative) - Beyond Grey Pinstripes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

IOM 581 Syllabus Page 8<br />

2/18 Product design and variety<br />

Mass customization assignment:<br />

Visit and explore two different mass customization websites for customized shoes, Nike iD (nikeid.nike.com) and mi<br />

adidas (www.adidas.com/products/miadidas/content, particularly items 1 and 2 under “Products” – do not compare with<br />

www.miadidas.com!).<br />

Discussion Questions:<br />

1. What are the main differences between the two approaches to mass customization? Which model is more difficult to<br />

implement and why?<br />

2. What are the main difficulties/issues that mass customization imposes on supply chains designed for mass<br />

production?<br />

2/23 Design for supply chain management<br />

Readings:<br />

� Chapter 4 Just-in-time (pp. 151-167) in Factory Physics: Foundations of Manufacturing Management by W. J. Hopp and<br />

M. L. Spearman, Irwin McGraw-Hill, Second edition, 2000<br />

Inventory centralization assignment: In solving the problems below, it may be best to set up spreadsheets to compute the<br />

answers (please submit it through the Blackboard, and hand in a printout) .<br />

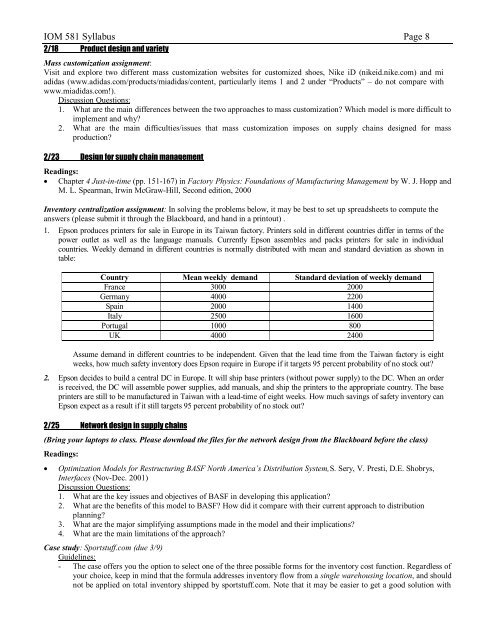

1. Epson produces printers for sale in Europe in its Taiwan factory. Printers sold in different countries differ in terms of the<br />

power outlet as well as the language manuals. Currently Epson assembles and packs printers for sale in individual<br />

countries. Weekly demand in different countries is normally distributed with mean and standard deviation as shown in<br />

table:<br />

Country Mean weekly demand Standard deviation of weekly demand<br />

France 3000 2000<br />

Germany 4000 2200<br />

Spain 2000 1400<br />

Italy 2500 1600<br />

Portugal 1000 800<br />

UK 4000 2400<br />

Assume demand in different countries to be independent. Given that the lead time from the Taiwan factory is eight<br />

weeks, how much safety inventory does Epson require in Europe if it targets 95 percent probability of no stock out?<br />

2. Epson decides to build a central DC in Europe. It will ship base printers (without power supply) to the DC. When an order<br />

is received, the DC will assemble power supplies, add manuals, and ship the printers to the appropriate country. The base<br />

printers are still to be manufactured in Taiwan with a lead-time of eight weeks. How much savings of safety inventory can<br />

Epson expect as a result if it still targets 95 percent probability of no stock out?<br />

2/25 Network design in supply chains<br />

(Bring your laptops to class. Please download the files for the network design from the Blackboard before the class)<br />

Readings:<br />

� Optimization Models for Restructuring BASF North America’s Distribution System,S. Sery, V. Presti, D.E. Shobrys,<br />

Interfaces (Nov-Dec. 2001)<br />

Discussion Questions:<br />

1. What are the key issues and objectives of BASF in developing this application?<br />

2. What are the benefits of this model to BASF? How did it compare with their current approach to distribution<br />

<strong>plan</strong>ning?<br />

3. What are the major simplifying assumptions made in the model and their implications?<br />

4. What are the main limitations of the approach?<br />

Case study: Sportstuff.com (due 3/9)<br />

Guidelines:<br />

- The case offers you the option to select one of the three possible forms for the inventory cost function. Regardless of<br />

your choice, keep in mind that the formula addresses inventory flow from a single warehousing location, and should<br />

not be applied on total inventory shipped by sportstuff.com. Note that it may be easier to get a good solution with