You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

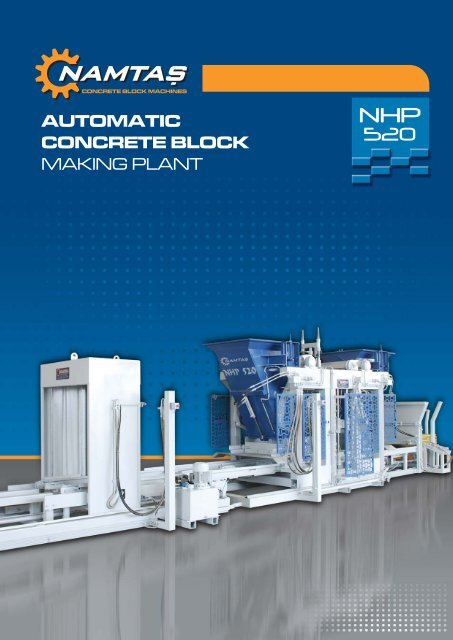

CONCRETE BLOCK MACHINES<br />

AUTOMATIC<br />

CONCRETE BLOCK<br />

MAKING PLANT<br />

NHP<br />

520

CONCRETE BLOCK MACHINES<br />

Professionalism Lies Beneath Details...<br />

Extensible frame, which is designed for rapid<br />

and easy mold change operations, minimizes<br />

the time spent for mold changing process and<br />

periodic maintenance.<br />

Recently developed pallet basket of the NHP-520 makes it possible<br />

to load empty pallets from 3 different locations. During pallet<br />

driving process, pallets on the top are lifted upwards to prevent<br />

friction so pallet lifetime is increased.<br />

Pallet stacking unit is located at the end of<br />

production line to stack pallets loaded with<br />

produced concrete blocks. This stacking process<br />

makes it possible to carry stacked pallets with<br />

forklifts to the stocking area easily and safely.<br />

Mimic control panel indicates all units of the plants<br />

on a graphical diagram so using the control panel<br />

became easy and practical.

CONCRETE BLOCK MACHINES<br />

AUTOMATIC<br />

CONCRETE BLOCK MAKING PLANT<br />

NHP<br />

520<br />

Absolute solution for medium<br />

business entrepreneurs<br />

NHP-520 is designed to fulfill the demands of medium business<br />

entrepreneurs in concrete block making industry. With its minimum<br />

first investment cost and scalable structure, NHP-520 is the ideal<br />

solution for the investors who are seeking to increase the overall<br />

quality of concrete products and to minimize manufacturing costs.

CONCRETE BLOCK MACHINES<br />

Proven quality in its industry<br />

PLC automation software, which is developed by NAMTAÞ R&D<br />

engineers, has proven its quality and reliability in manufacturing<br />

plants of many local and foreign enterprises. The whole plant<br />

operates automatic so production quality for each cycle and<br />

production capacity for each working shift are maintained and<br />

stabilized.<br />

Automation system also makes it possible to operate the plant in<br />

various speeds. A mimic control panel indicates all units of the<br />

plant on a graphical diagram so using the control panel became<br />

easy and practical. The operator can switch to manual operation<br />

anytime. Failure detection is also fast and easy with the mimic<br />

control panel.<br />

Scalable plants to fulfill various requirements<br />

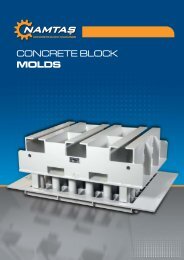

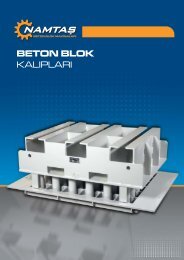

The NHP-520 is an automatic, stationary PLC concrete block<br />

making plant that is able to produce paving stones, curbstones<br />

and hollow blocks by using different molds on the machine. The<br />

machine produces concrete products on wooden or steel palettes.<br />

The plant consists of one NHP-520 automatic PLC block making<br />

machine with pallet stacking unit, one PLC spiral blade concrete<br />

mixer with a capacity of 600 lt./cycle, one 4x10 m³ aggregate<br />

silos and scaling unit and various conveying belts.

CONCRETE BLOCK MACHINES<br />

NHP 520<br />

Concrete Block Making Plant

CONCRETE BLOCK MACHINES<br />

NHP 520 - TECHNICAL SPECIFICATIONS:<br />

Control<br />

Automatic (PLC)<br />

Pallet Size<br />

950x950 mm.<br />

Usable Area on Pallet<br />

850x850 mm.<br />

Maximum Block Height<br />

200 mm.<br />

Minimum Block Height<br />

50 mm.<br />

Frame Dimensions (Width-Length-Height)<br />

2450x7300x2830<br />

Frame Weight.<br />

8.500 kg.<br />

Hydraulic Tank Capacity<br />

390 lt./520 lt.<br />

Material Bucket Capacity<br />

1.300 lt.<br />

Filling Box Capacity<br />

150 lt.<br />

Bottom Vibrators<br />

2x5,5 kW (max.50 kN)<br />

Top Vibrators<br />

2x0,5 kW (max.18 kN)<br />

Total Electric Motor Powers (Machine)<br />

35 kW<br />

Total Electric Motor Powers (Whole Plant)<br />

89 kW<br />

*This value is limited with the leg height of production pallets.<br />

Paving Stones<br />

Curbstones<br />

NHP 520 - PRODUCTION CAPACITY:<br />

Hollow Blocks<br />

Stones Per Cycle<br />

Production Capacity per Shift<br />

(8 hours)<br />

Behaton Paving Stone (163x198x80mm.)<br />

Rectangular Paving Stone (98x198x80mm.)<br />

Square Paving Stone (198x198x80mm.)<br />

Curbstone (180x700x300mm.)<br />

Curbstone (150x500x300mm.)<br />

Curbstone (100x500x200mm.)<br />

Hollow Block (190x390x190mm.)<br />

Hollow Block (150x390x190mm.)<br />

Hollow Block (100x390x190mm.)<br />

Behaton Paving Stone (163x198x80mm.)<br />

Rectangular Paving Stone (98x198x80mm.)<br />

Square Paving Stone (198x198x80mm.)<br />

Curbstone (180x700x300mm.)<br />

Curbstone (150x500x300mm.)<br />

Curbstone (100x500x200mm.)<br />

Hollow Block (190x390x190mm.)<br />

Hollow Block (150x390x190mm.)<br />

Hollow Block (100x390x190mm.)<br />

20 pieces<br />

32 pieces<br />

64 pieces<br />

2 pieces<br />

2 pieces<br />

4 pieces<br />

8 pieces<br />

10 pieces<br />

14 pieces<br />

550 m²<br />

640 m²<br />

640 m²<br />

2.000 pieces<br />

2.000 pieces<br />

4.000 pieces<br />

8.000 pieces<br />

10.000 pieces<br />

14.000 pieces<br />

CONCRETE MACHINES &<br />

CONCRETE PRODUCTS<br />

LTD. CO.<br />

a<br />

Ankara Asfaltý 26. km<br />

Kemalpaþa Ýzmir TURKEY<br />

These technical values are based on standard specifications and may vary on<br />

customer's requirements, installation type and location. NAMTAÞ keeps the right of<br />

changing technical specifications if necessary.<br />

Capacity value is theoretical value. It may vary according to aggregates structure,<br />

operator, weather and accommodation conditions.<br />

t<br />

f<br />

+90(232) 878 13 59<br />

+90(232) 878 77 65<br />

e info@namtas.com<br />

w www.namtas.com