FF7W/KM - CHR. WILLEMSEN Gmbh

FF7W/KM - CHR. WILLEMSEN Gmbh

FF7W/KM - CHR. WILLEMSEN Gmbh

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

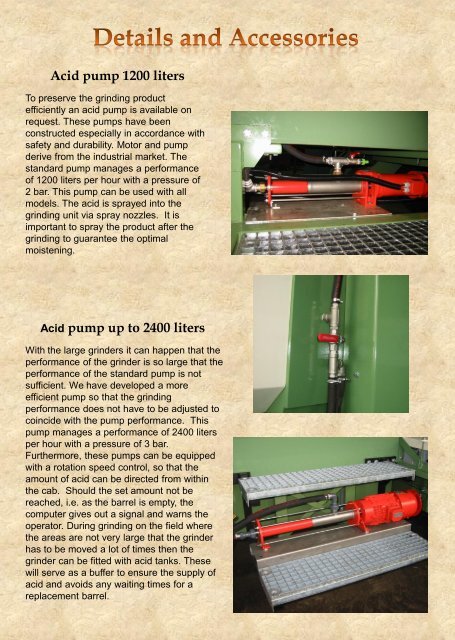

Acid pump 1200 liters<br />

To preserve the grinding product<br />

efficiently an acid pump is available on<br />

request. These pumps have been<br />

constructed especially in accordance with<br />

safety and durability. Motor and pump<br />

derive from the industrial market. The<br />

standard pump manages a performance<br />

of 1200 liters per hour with a pressure of<br />

2 bar. This pump can be used with all<br />

models. The acid is sprayed into the<br />

grinding unit via spray nozzles. It is<br />

important to spray the product after the<br />

grinding to guarantee the optimal<br />

moistening.<br />

Acid pump up to 2400 liters<br />

With the large grinders it can happen that the<br />

performance of the grinder is so large that the<br />

performance of the standard pump is not<br />

sufficient. We have developed a more<br />

efficient pump so that the grinding<br />

performance does not have to be adjusted to<br />

coincide with the pump performance. This<br />

pump manages a performance of 2400 liters<br />

per hour with a pressure of 3 bar.<br />

Furthermore, these pumps can be equipped<br />

with a rotation speed control, so that the<br />

amount of acid can be directed from within<br />

the cab. Should the set amount not be<br />

reached, i.e. as the barrel is empty, the<br />

computer gives out a signal and warns the<br />

operator. During grinding on the field where<br />

the areas are not very large that the grinder<br />

has to be moved a lot of times then the<br />

grinder can be fitted with acid tanks. These<br />

will serve as a buffer to ensure the supply of<br />

acid and avoids any waiting times for a<br />

replacement barrel.