Paper 9.1 - Steel Innovations Conference 2013 Christchurch-Ver4.pdf

Paper 9.1 - Steel Innovations Conference 2013 Christchurch-Ver4.pdf

Paper 9.1 - Steel Innovations Conference 2013 Christchurch-Ver4.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

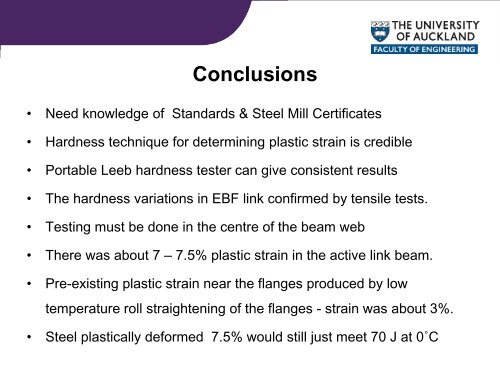

Conclusions<br />

• Need knowledge of Standards & <strong>Steel</strong> Mill Certificates<br />

• Hardness technique for determining plastic strain is credible<br />

• Portable Leeb hardness tester can give consistent results<br />

• The hardness variations in EBF link confirmed by tensile tests.<br />

• Testing must be done in the centre of the beam web<br />

• There was about 7 – 7.5% plastic strain in the active link beam.<br />

• Pre-existing plastic strain near the flanges produced by low<br />

temperature roll straightening of the flanges - strain was about 3%.<br />

• <strong>Steel</strong> plastically deformed 7.5% would still just meet 70 J at 0˚C