Secador Disecante - HHL Serie.pdf - remco srl

Secador Disecante - HHL Serie.pdf - remco srl

Secador Disecante - HHL Serie.pdf - remco srl

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

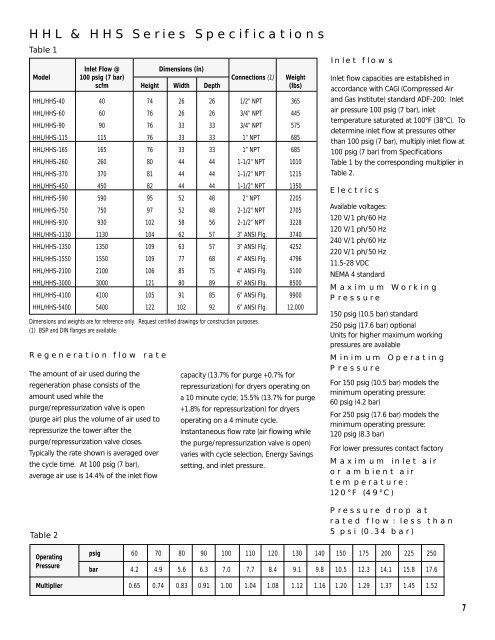

<strong>HHL</strong> & HHS <strong>Serie</strong>s Specifications<br />

Table 1<br />

Inlet Flow @<br />

Dimensions (in)<br />

Model 100 psig (7 bar) Connections (1) Weight<br />

scfm Height Width Depth (lbs)<br />

<strong>HHL</strong>/HHS-40 40 74 26 26 1/2” NPT 365<br />

<strong>HHL</strong>/HHS-60 60 76 26 26 3/4” NPT 445<br />

<strong>HHL</strong>/HHS-90 90 76 33 33 3/4” NPT 575<br />

<strong>HHL</strong>/HHS-115 115 76 33 33 1” NPT 685<br />

<strong>HHL</strong>/HHS-165 165 76 33 33 1” NPT 685<br />

<strong>HHL</strong>/HHS-260 260 80 44 44 1-1/2” NPT 1010<br />

<strong>HHL</strong>/HHS-370 370 81 44 44 1-1/2” NPT 1215<br />

<strong>HHL</strong>/HHS-450 450 82 44 44 1-1/2” NPT 1350<br />

<strong>HHL</strong>/HHS-590 590 95 52 48 2” NPT 2205<br />

<strong>HHL</strong>/HHS-750 750 97 52 48 2-1/2” NPT 2705<br />

<strong>HHL</strong>/HHS-930 930 102 58 56 2-1/2” NPT 3228<br />

<strong>HHL</strong>/HHS-1130 1130 104 62 57 3” ANSI Flg. 3740<br />

<strong>HHL</strong>/HHS-1350 1350 109 63 57 3” ANSI Flg. 4252<br />

<strong>HHL</strong>/HHS-1550 1550 109 77 68 4” ANSI Flg. 4796<br />

<strong>HHL</strong>/HHS-2100 2100 106 85 75 4” ANSI Flg. 5100<br />

<strong>HHL</strong>/HHS-3000 3000 121 80 89 6” ANSI Flg. 8500<br />

<strong>HHL</strong>/HHS-4100 4100 105 91 85 6” ANSI Flg. 9900<br />

<strong>HHL</strong>/HHS-5400 5400 122 102 92 6” ANSI Flg. 12,000<br />

Dimensions and weights are for reference only. Request certified drawings for construction purposes.<br />

(1) BSP and DIN flanges are available.<br />

Regeneration flow rate<br />

The amount of air used during the<br />

regeneration phase consists of the<br />

amount used while the<br />

purge/repressurization valve is open<br />

(purge air) plus the volume of air used to<br />

repressurize the tower after the<br />

purge/repressurization valve closes.<br />

Typically the rate shown is averaged over<br />

the cycle time. At 100 psig (7 bar),<br />

average air use is 14.4% of the inlet flow<br />

capacity (13.7% for purge +0.7% for<br />

repressurization) for dryers operating on<br />

a 10 minute cycle; 15.5% (13.7% for purge<br />

+1.8% for repressurization) for dryers<br />

operating on a 4 minute cycle.<br />

Instantaneous flow rate (air flowing while<br />

the purge/repressurization valve is open)<br />

varies with cycle selection, Energy Savings<br />

setting, and inlet pressure.<br />

Inlet flows<br />

Inlet flow capacities are established in<br />

accordance with CAGI (Compressed Air<br />

and Gas Institute) standard ADF-200: Inlet<br />

air pressure 100 psig (7 bar), inlet<br />

temperature saturated at 100°F (38°C). To<br />

determine inlet flow at pressures other<br />

than 100 psig (7 bar), multiply inlet flow at<br />

100 psig (7 bar) from Specifications<br />

Table 1 by the corresponding multiplier in<br />

Table 2.<br />

Electrics<br />

Available voltages:<br />

120 V/1 ph/60 Hz<br />

120 V/1 ph/50 Hz<br />

240 V/1 ph/60 Hz<br />

220 V/1 ph/50 Hz<br />

11.5-28 VDC<br />

NEMA 4 standard<br />

Maximum Working<br />

Pressure<br />

150 psig (10.5 bar) standard<br />

250 psig (17.6 bar) optional<br />

Units for higher maximum working<br />

pressures are available<br />

Minimum Operating<br />

Pressure<br />

For 150 psig (10.5 bar) models the<br />

minimum operating pressure:<br />

60 psig (4.2 bar)<br />

For 250 psig (17.6 bar) models the<br />

minimum operating pressure:<br />

120 psig (8.3 bar)<br />

For lower pressures contact factory<br />

Maximum inlet air<br />

or ambient air<br />

temperature:<br />

120°F (49°C)<br />

Table 2<br />

Operating<br />

Pressure<br />

Pressure drop at<br />

rated flow: less than<br />

5 psi (0.34 bar)<br />

psig 60 70 80 90 100 110 120 130 140 150 175 200 225 250<br />

bar 4.2 4.9 5.6 6.3 7.0 7.7 8.4 9.1 9.8 10.5 12.3 14.1 15.8 17.6<br />

Multiplier 0.65 0.74 0.83 0.91 1.00 1.04 1.08 1.12 1.16 1.20 1.29 1.37 1.45 1.52<br />

7