Anchor Meadow Stone - Pavestone

Anchor Meadow Stone - Pavestone

Anchor Meadow Stone - Pavestone

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Anchor</strong> <strong>Meadow</strong> <strong>Stone</strong> ®<br />

The new <strong>Anchor</strong> <strong>Meadow</strong> <strong>Stone</strong> ® has attractive earthtone blends and a<br />

rough-hewn texture that achieves the look and feel of natural stone. A flexible, easy-toinstall<br />

3-piece system, the <strong>Anchor</strong> <strong>Meadow</strong> <strong>Stone</strong> ® can reach a height of 2 1 / 2’ (750 mm)<br />

and is a more reliable alternative to timber, boulder or field stone walls. Each stone sold<br />

individually. Retaining wall design and construction vary based on product applicability,<br />

site conditions and local building code regulations. Engineering may be necessary.<br />

COMPOSITION AND MANUFACTURE<br />

<strong>Anchor</strong> <strong>Meadow</strong> <strong>Stone</strong> ® is made from a “no slump” concrete mix. Made under extreme<br />

pressure and high frequency vibrations, <strong>Anchor</strong> <strong>Meadow</strong> <strong>Stone</strong> ® has a compressive<br />

strength greater than 4000psi, a water absorption maximum of 7%.<br />

INSTALLATION<br />

Depending on site conditions and or local building codes, engineering may be required.<br />

Step 1 - Site Preparation: Stake out project. Place a string line level on each string line and<br />

adjust to where all lines are level. Measure down in wall increments using the height of<br />

the wall stone to determine placement of the top of the wall courses. For small landscape<br />

walls (3 courses or less) it is required that the first course be at least partially buried. For<br />

tall walls (4 to 8 courses) the first course should be fully buried at a minimum.<br />

Step 2 - Excavation: All walls require excavation for a prepared base material that<br />

extends a minimum of six (6) inches in front and back of the wall. For small walls, dig<br />

this trench a minimum half the height of the wall stone deep. For tall walls, dig your<br />

trench to a minimum depth of a full wall stone height. Compact floor of this trench<br />

with a compactor or hand tamper.<br />

Step 3 - Base Preparation: For small walls base preparation, an option would be to place<br />

a mixture of dry sand and Portland cement (one shovel of Portland to four shovels of<br />

sand). Place the sand-cement mixture a minimum of four (4) inches at the bottom of the<br />

trench. For tall walls, you’ll need a more substantial base. Granular road base is<br />

preferable at a minimum four (4) inch placement. Compact the material with a<br />

compactor or hand tamper. Engineering may be required.<br />

Step 4 - Leveling: For both small and tall walls a maximum of one-half inch of coarse sand<br />

is allowable to level the top profile of the base material. When placing wall stones, level<br />

the surface of all wall stones in both directions with a carpenter’s level. Replace the<br />

string-line where the top of your wall course will be and check for horizontal level prior<br />

to each course installation.<br />

Step 5 - Laying <strong>Stone</strong>s: Always begin at the lowest point of the wall. Level each stone in<br />

both directions with a minimum two (2) foot carpenter’s level. Once the base course is<br />

complete, continue assembling additional courses by positioning the stones in a running<br />

bond pattern relative to the course beneath, taking care not to align joints vertically.<br />

Securely engage the stone to the lower stones. Backfill and compact material behind the<br />

wall in a four (4) inch to a maximum six (6) inch layer. Install a granular no fines<br />

material as a drainage zone a minimum of four (4) to six (6) inches thickness directly<br />

behind the wall. Compact materials with a compactor or hand tamper. A four (4) inch<br />

perforated plastic pipe may be required behind wall.<br />

Step 6 - Cutting <strong>Stone</strong>s: When building your wall, you may need partial stones to finish<br />

coursing. Place the to-be-cut stone at its finished position in the wall. Mark the cut line.<br />

Typically, a mechanical splitter or gasoline powered concrete hand saw are used to<br />

facilitate cutting of stone. An alternative may be to use a hammer and a chisel. Place<br />

the stone on a hard surface. Position the chisel at the cut mark and proceed to hammer<br />

the chisel scoring the cut line. Score the stone on all sides. Once the perimeter score is<br />

complete, strike the chisel on the score line until it breaks. Always use safety glasses,<br />

gloves and applicable safety standards.<br />

Complete installation and specification details are available by contacting your <strong>Pavestone</strong><br />

Sales Representative.<br />

Note: Colors are shown as accurately as possible in brochures & samples, but due to the nature of the<br />

product, regional color differences and variables in print reproduction, colors may not match exactly.<br />

APPLICATIONS<br />

Landscape Retaining Walls • Tree Rings • Planter<br />

Beds • Garden Terraces • Raised Planters<br />

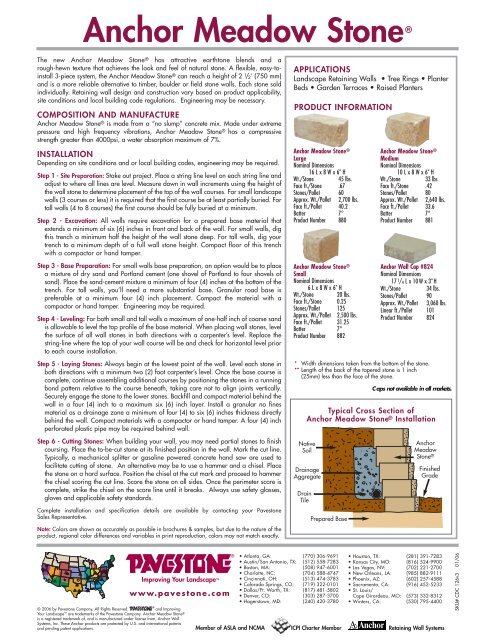

PRODUCT INFORMATION<br />

<strong>Anchor</strong> <strong>Meadow</strong> <strong>Stone</strong> ®<br />

Large<br />

Nominal Dimensions<br />

16 L x 8 W x 6" H<br />

Wt./<strong>Stone</strong> 45 lbs.<br />

Face ft./<strong>Stone</strong> .67<br />

<strong>Stone</strong>s/Pallet 60<br />

Approx. Wt./Pallet 2,700 lbs.<br />

Face ft./Pallet 40.2<br />

Batter 7°<br />

Product Number 880<br />

<strong>Anchor</strong> <strong>Meadow</strong> <strong>Stone</strong> ®<br />

Small<br />

Nominal Dimensions<br />

6 L x 8 W x 6" H<br />

Wt./<strong>Stone</strong> 20 lbs.<br />

Face ft./<strong>Stone</strong> 0.25<br />

<strong>Stone</strong>s/Pallet 125<br />

Approx. Wt./Pallet 2,500 lbs.<br />

Face ft./Pallet 31.25<br />

Batter 7°<br />

Product Number 882<br />

Native<br />

Soil<br />

Drainage<br />

Aggregate<br />

Drain<br />

Tile<br />

Prepared Base<br />

<strong>Anchor</strong> <strong>Meadow</strong> <strong>Stone</strong> ®<br />

Medium<br />

Nominal Dimensions<br />

10 L x 8 W x 6" H<br />

Wt./<strong>Stone</strong> 33 lbs.<br />

Face ft./<strong>Stone</strong> .42<br />

<strong>Stone</strong>s/Pallet 80<br />

Approx. Wt./Pallet 2,640 lbs.<br />

Face ft./Pallet 33.6<br />

Batter 7°<br />

Product Number 881<br />

<strong>Anchor</strong> Wall Cap #824<br />

Nominal Dimensions<br />

17 1 / 4 L x 10 W x 3" H<br />

Wt./<strong>Stone</strong> 34 lbs.<br />

<strong>Stone</strong>s/Pallet 90<br />

Approx. Wt./Pallet 3,060 lbs.<br />

Linear ft./Pallet 101<br />

Product Number 824<br />

* Width dimensions taken from the bottom of the stone.<br />

** Length of the back of the tapered stone is 1 inch<br />

(25mm) less than the face of the stone.<br />

Caps not available in all markets.<br />

Typical Cross Section of<br />

<strong>Anchor</strong> <strong>Meadow</strong> <strong>Stone</strong> ® Installation<br />

<strong>Anchor</strong><br />

<strong>Meadow</strong><br />

<strong>Stone</strong> ®<br />

Finished<br />

Grade<br />

w w w. p a v e s t o n e . c o m<br />

© 2006 by <strong>Pavestone</strong> Company. All Rights Reserved. and Improving<br />

Your Landscape are trademarks of the <strong>Pavestone</strong> Company. <strong>Anchor</strong> <strong>Meadow</strong> <strong>Stone</strong> ®<br />

is a registered trademark of, and is manufactured under license from, <strong>Anchor</strong> Wall<br />

Systems, Inc. These <strong>Anchor</strong> products are protected by U.S. and international patents<br />

and pending patent applications.<br />

Member of ASLA and NCMA<br />

• Atlanta, GA: (770) 306-9691<br />

• Austin/San Antonio, TX: (512) 558-7283<br />

• Boston, MA: (508) 947-6001<br />

• Charlotte, NC: (704) 588-4747<br />

• Cincinnati, OH: (513) 474-3783<br />

• Colorado Springs, CO: (719) 322-0101<br />

• Dallas/Ft. Worth, TX: (817) 481-5802<br />

• Denver, CO: (303) 287-3700<br />

• Hagerstown, MD: (240) 420-3780<br />

ICPI Charter Member<br />

• Houston, TX: (281) 391-7283<br />

• Kansas City, MO: (816) 524-9900<br />

• Las Vegas, NV: (702) 221-2700<br />

• New Orleans, LA: (985) 882-9111<br />

• Phoenix, AZ: (602) 257-4588<br />

• Sacramento, CA: (916) 452-5233<br />

• St. Louis/<br />

Cape Girardeau, MO: (573) 332-8312<br />

• Winters, CA: (530) 795-4400<br />

Retaining Wall Systems<br />

SKU# CDC 126v3 01/06