Asphalt Technology News - Auburn University

Asphalt Technology News - Auburn University

Asphalt Technology News - Auburn University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

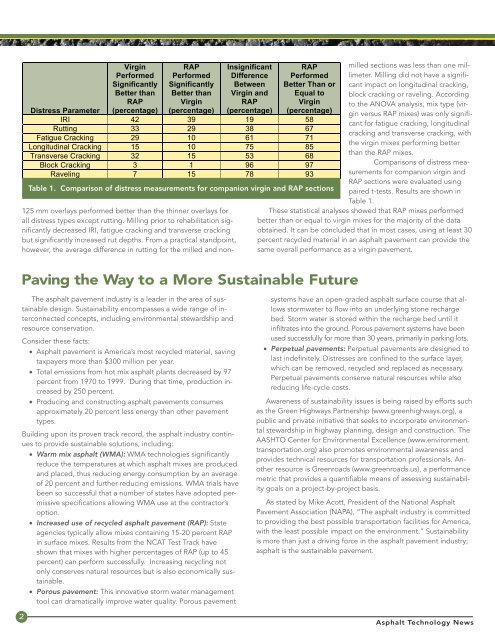

Comparisons of distress measurements for companion virgin and RAP sections were evaluated using pairedt-tests. Results are shown in Table 1.Table 1. Comparison of distress measurements for companion virgin and RAP sectionsDistress ParameterVirginPerformedSignificantlyBetter thanRAP(percentage)RAPPerformedSignificantlyBetter thanVirgin(percentage)InsignificantDifferenceBetweenVirgin andRAP(percentage)RAPPerformedBetter Than orEqual toVirgin(percentage)IRI 42 39 19 58Rutting 33 29 38 67Fatigue Cracking 29 10 61 71Longitudinal Cracking 15 10 75 85Transverse Cracking 32 15 53 68Block Cracking 3 1 96 97Raveling 7 15 78 93These statistical analyses showed that RAP mixes performed better than or equal to virgin mixes for theJerry Chris Jones! 9/3/09 10:57 AMDeleted: one-samplemilled sections was less than one millimeter.Milling did not have a significantimpact on longitudinal cracking,block cracking or raveling. Accordingto the ANOVA analysis, mix type (virginversus RAP mixes) was only significantfor fatigue cracking, longitudinalcracking and transverse cracking, withthe virgin mixes performing betterthan the RAP mixes.Comparisons of distress measurementsfor companion virgin andRAP sections were evaluated usingpaired t-tests. Results are shown inTable 1.These statistical analyses showed that RAP mixes performedbetter than or equal to virgin mixes for the majority of the dataobtained. It can be concluded that in most cases, using at least 30percent recycled material in an asphalt pavement can provide thesame overall performance as a virgin pavement.Paving the Way to a More Sustainable FutureThe asphalt pavement industry is a leader in the area of sustainabledesign. Sustainability encompasses a wide range of interconnectedconcepts, including environmental stewardship andresource conservation.Consider these facts:• <strong>Asphalt</strong> pavement is America’s most recycled material, savingtaxpayers more than $300 million per year.• Total emissions from hot mix asphalt plants decreased by 97percent from 1970 to 1999. During that time, production increasedby 250 percent.• Producing and constructing asphalt pavements consumesapproximately 20 percent less energy than other pavementtypes.Building upon its proven track record, the asphalt industry continuesto provide sustainable solutions, including:• Warm mix asphalt (WMA): WMA technologies significantlyreduce the temperatures at which asphalt mixes are producedand placed, thus reducing energy consumption by an averageof 20 percent and further reducing emissions. WMA trials havebeen so successful that a number of states have adopted permissivespecifications allowing WMA use at the contractor’soption.• Increased use of recycled asphalt pavement (RAP): Stateagencies typically allow mixes containing 15-20 percent RAPin surface mixes. Results from the NCAT Test Track haveshown that mixes with higher percentages of RAP (up to 45percent) can perform successfully. Increasing recycling notonly conserves natural resources but is also economically sustainable.• Porous pavement: This innovative storm water managementtool can dramatically improve water quality. Porous pavement2majority of the data obtained. It can be concluded that in most cases, using at least 30 percent recycled125 material mm in overlays an asphalt performed pavement better can provide than the the thinner same overall overlays performance as a virgin pavement.all distress types except rutting. Milling prior to rehabilitation significantlydecreased IRI, fatigue cracking and transverse crackingbut significantly increased rut depths. From a practical standpoint,however, the average difference in rutting for the milled and nonsystemshave an open-graded asphalt surface course that allowsstormwater to flow into an underlying stone rechargebed. Storm water is stored within the recharge bed until itinfiltrates into the ground. Porous pavement systems have beenused successfully for more than 30 years, primarily in parking lots.• Perpetual pavements: Perpetual pavements are designed tolast indefinitely. Distresses are confined to the surface layer,which can be removed, recycled and replaced as necessary.Perpetual pavements conserve natural resources while alsoreducing life-cycle costs.Awareness of sustainability issues is being raised by efforts suchas the Green Highways Partnership (www.greenhighways.org), apublic and private initiative that seeks to incorporate environmentalstewardship in highway planning, design and construction. TheAASHTO Center for Environmental Excellence (www.environment.transportation.org) also promotes environmental awareness andprovides technical resources for transportation professionals. Anotherresource is Greenroads (www.greenroads.us), a performancemetric that provides a quantifiable means of assessing sustainabilitygoals on a project-by-project basis.As stated by Mike Acott, President of the National <strong>Asphalt</strong>Pavement Association (NAPA), “The asphalt industry is committedto providing the best possible transportation facilities for America,with the least possible impact on the environment.” Sustainabilityis more than just a driving force in the asphalt pavement industry;asphalt is the sustainable pavement.<strong>Asphalt</strong> <strong>Technology</strong> <strong>News</strong>