Sioux Tools Industrial Catalog

Sioux Tools Industrial Catalog

Sioux Tools Industrial Catalog

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

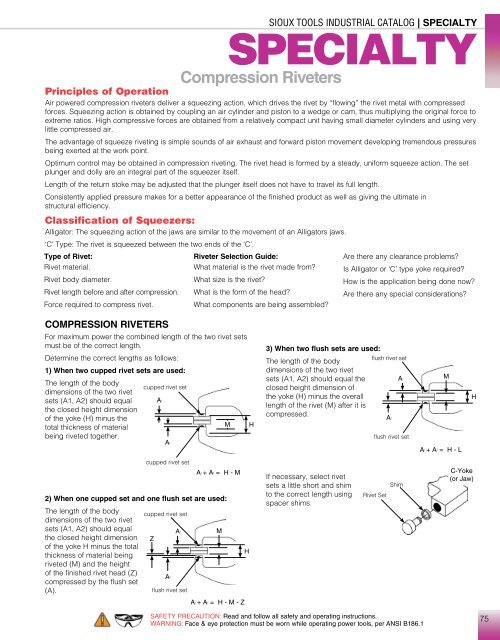

Principles of OperationAir powered compression riveters deliver a squeezing action, which drives the rivet by “flowing” the rivet metal with compressedforces. Squeezing action is obtained by coupling an air cylinder and piston to a wedge or cam, thus multiplying the original force toextreme ratios. High compressive forces are obtained from a relatively compact unit having small diameter cylinders and using verylittle compressed air.The advantage of squeeze riveting is simple sounds of air exhaust and forward piston movement developing tremendous pressuresbeing exerted at the work point.Optimum control may be obtained in compression riveting. The rivet head is formed by a steady, uniform squeeze action. The setplunger and dolly are an integral part of the squeezer itself.Length of the return stoke may be adjusted that the plunger itself does not have to travel its full length.Consistently applied pressure makes for a better appearance of the finished product as well as giving the ultimate instructural efficiency.Classification of Squeezers:Alligator: The squeezing action of the jaws are similar to the movement of an Alligators jaws.‘C’ Type: The rivet is squeezed between the two ends of the ‘C’.Type of Rivet:Rivet material.Rivet body diameter.Rivet length before and after compression.Force required to compress rivet.SPECIALTYCompression RivetersRiveter Selection Guide:What material is the rivet made from?What size is the rivet?What is the form of the head?What components are being assembled?SIOUX TOOLS INDUSTRIAL CATALOG | SPECIALTYAre there any clearance problems?Is Alligator or ‘C’ type yoke required?How is the application being done now?Are there any special considerations?COMPRESSION RIVETERSFor maximum power the combined length of the two rivet setsmust be of the correct length.Determine the correct lengths as follows:1) When two cupped rivet sets are used:The length of the bodycupped rivet setdimensions of the two rivetsets (A1, A2) should equalthe closed height dimensionof the yoke (H) minus thetotal thickness of materialMbeing riveted together.H3) When two flush sets are used:flush rivet setThe length of the bodydimensions of the two rivetsets (A1, A2) should equal the A 1closed height dimension ofthe yoke (H) minus the overalllength of the rivet (M) after it iscompressed.A 2flush rivet setMHA 1 + A 2 = H - LA 1 A 2 A 1 + A 2 = H - Mcupped rivet set2) When one cupped set and one flush set are used:The length of the bodydimensions of the two rivetcupped rivet setsets (A1, A2) should equalthe closed height dimension Zof the yoke H minus the totalthickness of material beingriveted (M) and the heightA 1Mof the finished rivet head (Z)compressed by the flush set(A).A 2flush rivet setHIf necessary, select rivetsets a little short and shimto the correct length usingspacer shims.Rivet SetShimC-Yoke(or Jaw)A 1 + A 2 = H - M - ZSAFETY PRECAUTION: Read and follow all safety and operating instructions.WARNING: Face & eye protection must be worn while operating power tools, per ANSI B186.175