UNI-PURE™ DW and DW-L Specialty Starches - Anshul Life Sciences

UNI-PURE™ DW and DW-L Specialty Starches - Anshul Life Sciences

UNI-PURE™ DW and DW-L Specialty Starches - Anshul Life Sciences

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

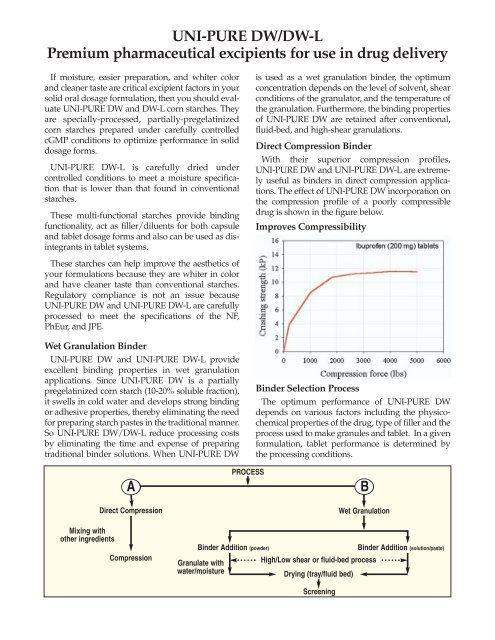

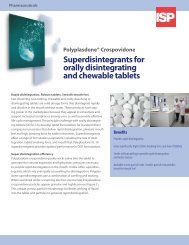

<strong>UNI</strong>-PURE <strong>DW</strong>/<strong>DW</strong>-LPremium pharmaceutical excipients for use in drug deliveryIf moisture, easier preparation, <strong>and</strong> whiter color<strong>and</strong> cleaner taste are critical excipient factors in yoursolid oral dosage formulation, then you should evaluate<strong>UNI</strong>-PURE <strong>DW</strong> <strong>and</strong> <strong>DW</strong>-L corn starches. Theyare specially-processed, partially-pregelatinizedcorn starches prepared under carefully controlledcGMP conditions to optimize performance in soliddosage forms.<strong>UNI</strong>-PURE <strong>DW</strong>-L is carefully dried undercontrolled conditions to meet a moisture specificationthat is lower than that found in conventionalstarches.These multi-functional starches provide bindingfunctionality, act as filler/diluents for both capsule<strong>and</strong> tablet dosage forms <strong>and</strong> also can be used as disintegrantsin tablet systems.These starches can help improve the aesthetics ofyour formulations because they are whiter in color<strong>and</strong> have cleaner taste than conventional starches.Regulatory compliance is not an issue because<strong>UNI</strong>-PURE <strong>DW</strong> <strong>and</strong> <strong>UNI</strong>-PURE <strong>DW</strong>-L are carefullyprocessed to meet the specifications of the NF,PhEur, <strong>and</strong> JPE.Wet Granulation Binder<strong>UNI</strong>-PURE <strong>DW</strong> <strong>and</strong> <strong>UNI</strong>-PURE <strong>DW</strong>-L provideexcellent binding properties in wet granulationapplications. Since <strong>UNI</strong>-PURE <strong>DW</strong> is a partiallypregelatinized corn starch (10-20% soluble fraction),it swells in cold water <strong>and</strong> develops strong bindingor adhesive properties, thereby eliminating the needfor preparing starch pastes in the traditional manner.So <strong>UNI</strong>-PURE <strong>DW</strong>/<strong>DW</strong>-L reduce processing costsby eliminating the time <strong>and</strong> expense of preparingtraditional binder solutions. When <strong>UNI</strong>-PURE <strong>DW</strong>is used as a wet granulation binder, the optimumconcentration depends on the level of solvent, shearconditions of the granulator, <strong>and</strong> the temperature ofthe granulation. Furthermore, the binding propertiesof <strong>UNI</strong>-PURE <strong>DW</strong> are retained after conventional,fluid-bed, <strong>and</strong> high-shear granulations.Direct Compression BinderWith their superior compression profiles,<strong>UNI</strong>-PURE <strong>DW</strong> <strong>and</strong> <strong>UNI</strong>-PURE <strong>DW</strong>-L are extremelyuseful as binders in direct compression applications.The effect of <strong>UNI</strong>-PURE <strong>DW</strong> incorporation onthe compression profile of a poorly compressibledrug is shown in the figure below.Improves CompressibilityBinder Selection ProcessThe optimum performance of <strong>UNI</strong>-PURE <strong>DW</strong>depends on various factors including the physicochemicalproperties of the drug, type of filler <strong>and</strong> theprocess used to make granules <strong>and</strong> tablet. In a givenformulation, tablet performance is determined bythe processing conditions.ADirect CompressionPROCESSBWet GranulationMixing withother ingredientsCompressionBinder Addition (powder)Binder Addition (solution/paste)Granulate withwater/moistureHigh/Low shear or fluid-bed processDrying (tray/fluid bed)Screening