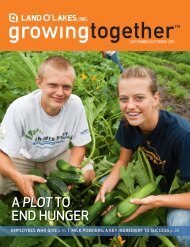

2011 March/April Issue - Land O'Lakes Inc.

2011 March/April Issue - Land O'Lakes Inc.

2011 March/April Issue - Land O'Lakes Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A truck picks up milk at Hilltop Dairy in St. Charles, Minn.are full,” he said. “During the storm, weclose up barns to keep snow out of stallsand troughs. We remove snow from thebunker silo and commodity sheds to preventfeed from getting wet, and we tryhard to maintain both feeding and milkingschedules so we do not upset the cows.”These steps not only protect the herdfrom the elements, but also provide thebest opportunity to maintain optimal productionthrough the duration of the storm.With production running on schedule,the next step for producers is to maintaintheir facility’s accessibility.“We have several large four-wheeldrivetractors with plows and chainsthat we prepare in advance of storms,”said Kreider. “We remove snow fromdriveways and around the buildings. Wealso help clear our local roads, if necessary– which, if nothing else, makes theneighbors happy.”By clearing snow from the driveway andarea roads, the producer is making it possiblefor the hauler to pick up and removetheir milk safely – preventing milk frombeing wasted. This effort does not go unnoticedby haulers, and allows them to focuson safely navigating through the stormwhich is not a simple task.“We try and start the routes early, gettinga jump on the storm,” Nordtvedt said.“We also use several different optionsBy clearing snow from thedriveway and area roads,the producer is making itpossible for the hauler topick up and remove their milksafely – preventing milkfrom being wasted.during the storm, including dispatchingadditional drivers and trucks, callingahead to ensure roadways are clear and usinga system called ‘drop and hook,’ whereone driver fills a trailer with milk, drops itoff and returns an empty trailer, while anotherdriver delivers the filled trailer to theprocessing facility.”Successfully producingand transportingmilk are obviously crucialto managing supplythrough a winterstorm, but it is all fornaught if the processingfacility is unable toremain open. For thisreason, it is imperativefor <strong>Land</strong> O’Lakes dairyfacilities to maintainoperations regardlessof the weather.<strong>Land</strong> O’Lakes Carlisle Plant ManagerDonald Holtan said the first, and most important,step in doing so is providing a safeenvironment for employees.“From an employee safety standpoint,we make sure we are keeping the parkinglots and sidewalks clear of snow andice,” he said. “In the case of a very severestorm, the plant makes arrangementswith the local inn so, in the event of aheavy snowfall, our employees who havelong commutes have a more convenientplace to stay.”Holtan said this is also beneficial becauseit better guarantees that employees will beable to safely return to work the followingday – thus maintaining plant operations.Once employees are in the buildingsafely, the plant focuses on being readyand able to receive milk upon arrival. Thebest way to do so, according to Holtan, issimply to maintain “business as usual.”“We keep the plant open and are veryflexible to changes in delivery times,” hesaid. “That way, when the haulers showup, we are ready to go.”Although this winter may have presentedmany obstacles, the combination of experience,teamwork and discipline has allowed<strong>Land</strong> O’Lakes member milk to continue beingproduced, transported and processedeach day – regardless of the forecast. ■Even in deep snowfalls, producers aim to keep the cows on schedule.www.landolakesinc.com MARCH/APRIL <strong>2011</strong> 21