F48 - Advanced Plastics

F48 - Advanced Plastics

F48 - Advanced Plastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

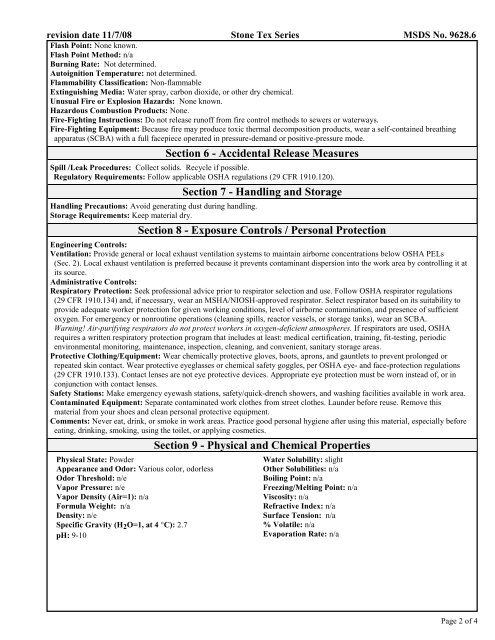

evision date 11/7/08 Stone Tex Series MSDS No. 9628.6Flash Point: None known.Flash Point Method: n/aBurning Rate: Not determined.Autoignition Temperature: not determined.Flammability Classification: Non-flammableExtinguishing Media: Water spray, carbon dioxide, or other dry chemical.Unusual Fire or Explosion Hazards: None known.Hazardous Combustion Products: None.Fire-Fighting Instructions: Do not release runoff from fire control methods to sewers or waterways.Fire-Fighting Equipment: Because fire may produce toxic thermal decomposition products, wear a self-contained breathingapparatus (SCBA) with a full facepiece operated in pressure-demand or positive-pressure mode.Section 6 - Accidental Release MeasuresSpill /Leak Procedures: Collect solids. Recycle if possible.Regulatory Requirements: Follow applicable OSHA regulations (29 CFR 1910.120).Handling Precautions: Avoid generating dust during handling.Storage Requirements: Keep material dry.Section 7 - Handling and StorageSection 8 - Exposure Controls / Personal ProtectionEngineering Controls:Ventilation: Provide general or local exhaust ventilation systems to maintain airborne concentrations below OSHA PELs(Sec. 2). Local exhaust ventilation is preferred because it prevents contaminant dispersion into the work area by controlling it atits source.Administrative Controls:Respiratory Protection: Seek professional advice prior to respirator selection and use. Follow OSHA respirator regulations(29 CFR 1910.134) and, if necessary, wear an MSHA/NIOSH-approved respirator. Select respirator based on its suitability toprovide adequate worker protection for given working conditions, level of airborne contamination, and presence of sufficientoxygen. For emergency or nonroutine operations (cleaning spills, reactor vessels, or storage tanks), wear an SCBA.Warning! Air-purifying respirators do not protect workers in oxygen-deficient atmospheres. If respirators are used, OSHArequires a written respiratory protection program that includes at least: medical certification, training, fit-testing, periodicenvironmental monitoring, maintenance, inspection, cleaning, and convenient, sanitary storage areas.Protective Clothing/Equipment: Wear chemically protective gloves, boots, aprons, and gauntlets to prevent prolonged orrepeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations(29 CFR 1910.133). Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or inconjunction with contact lenses.Safety Stations: Make emergency eyewash stations, safety/quick-drench showers, and washing facilities available in work area.Contaminated Equipment: Separate contaminated work clothes from street clothes. Launder before reuse. Remove thismaterial from your shoes and clean personal protective equipment.Comments: Never eat, drink, or smoke in work areas. Practice good personal hygiene after using this material, especially beforeeating, drinking, smoking, using the toilet, or applying cosmetics.Physical State: PowderAppearance and Odor: Various color, odorlessOdor Threshold: n/eVapor Pressure: n/eVapor Density (Air=1): n/aFormula Weight: n/aDensity: n/eSpecific Gravity (H 2 O=1, at 4 °C): 2.7pH: 9-10Section 9 - Physical and Chemical PropertiesWater Solubility: slightOther Solubilities: n/aBoiling Point: n/aFreezing/Melting Point: n/aViscosity: n/aRefractive Index: n/aSurface Tension: n/a% Volatile: n/aEvaporation Rate: n/aPage 2 of 4