Download - Hydrex Underwater Technology

Download - Hydrex Underwater Technology

Download - Hydrex Underwater Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

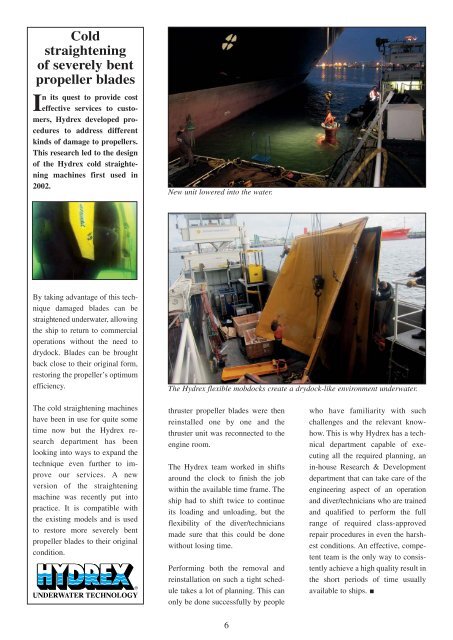

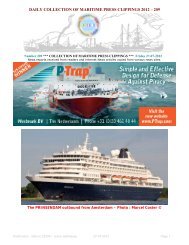

Coldstraighteningof severely bentpropeller bladesIn its quest to provide costeffective services to customers,<strong>Hydrex</strong> developed proceduresto address differentkinds of damage to propellers.This research led to the designof the <strong>Hydrex</strong> cold straighteningmachines first used in2002.New unit lowered into the water.By taking advantage of this techniquedamaged blades can bestraightened underwater, allowingthe ship to return to commercialoperations without the need todrydock. Blades can be broughtback close to their original form,restoring the propeller’s optimumefficiency.The <strong>Hydrex</strong> flexible mobdocks create a drydock-like environment underwater.The cold straightening machineshave been in use for quite sometime now but the <strong>Hydrex</strong> researchdepartment has beenlooking into ways to expand thetechnique even further to improveour services. A newversion of the straighteningmachine was recently put intopractice. It is compatible withthe existing models and is usedto restore more severely bentpropeller blades to their originalcondition.thruster propeller blades were thenreinstalled one by one and thethruster unit was reconnected to theengine room.The <strong>Hydrex</strong> team worked in shiftsaround the clock to finish the jobwithin the available time frame. Theship had to shift twice to continueits loading and unloading, but theflexibility of the diver/techniciansmade sure that this could be donewithout losing time.Performing both the removal andreinstallation on such a tight scheduletakes a lot of planning. This canonly be done successfully by peoplewho have familiarity with suchchallenges and the relevant knowhow.This is why <strong>Hydrex</strong> has a technicaldepartment capable of executingall the required planning, anin-house Research & Developmentdepartment that can take care of theengineering aspect of an operationand diver/technicians who are trainedand qualified to perform the fullrange of required class-approvedrepair procedures in even the harshestconditions. An effective, competentteam is the only way to consistentlyachieve a high quality result inthe short periods of time usuallyavailable to ships.6