R - Hastings

R - Hastings

R - Hastings

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

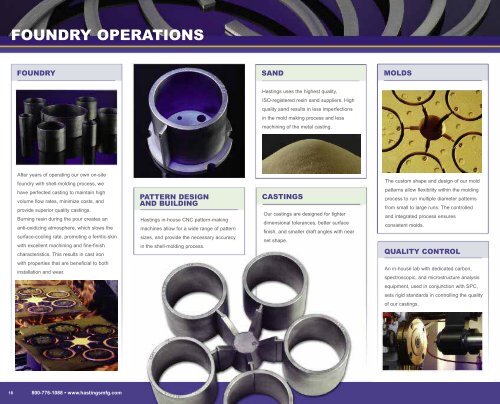

FOUNDRY OPERATIONSFOUNDRYSANDMOLDS<strong>Hastings</strong> uses the highest quality,ISO-registered resin sand suppliers. Highquality sand results in less imperfectionsin the mold making process and lessmachining of the metal casting.After years of operating our own on-sitefoundry with shell-molding process, wehave perfected casting to maintain highvolume flow rates, minimize costs, andprovide superior quality castings.Burning resin during the pour creates ananti-oxidizing atmosphere, which slows thesurface-cooling rate, promoting a ferritic-skinwith excellent machining and fine-finishcharacteristics. This results in cast ironPATTERN DESIGNAND BUILDING<strong>Hastings</strong> in-house CNC pattern-makingmachines allow for a wide range of patternsizes, and provide the necessary accuracyin the shell-molding process.CASTINGSOur castings are designed for tighterdimensional tolerances, better surfacefinish, and smaller draft angles with nearnet shape.The custom shape and design of our moldpatterns allow flexibility within the moldingprocess to run multiple diameter patternsfrom small to large runs. The controlledand integrated process ensuresconsistent molds.QUALITY CONTROLwith properties that are beneficial to bothinstallation and wear.An in-house lab with dedicated carbon,spectroscopic, and microstructure analysisequipment, used in conjunction with SPC,sets rigid standards in controlling the qualityof our castings.18800-776-1088 • www.hastingsmfg.com