You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

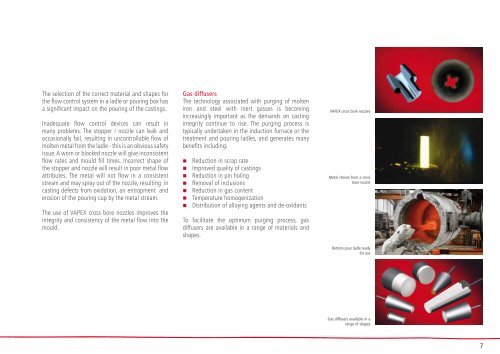

The selection of the correct material and shapes forthe flow control system in a ladle or pouring box hasa significant impact on the pouring of the castings.Inadequate flow control devices can result inmany problems. The stopper / nozzle can leak andoccasionally fail, resulting in uncontrollable flow ofmolten metal from the ladle - this is an obvious safetyissue. A worn or blocked nozzle will give inconsistentflow rates and mould fill times. Incorrect shape ofthe stopper and nozzle will result in poor metal flowattributes. The metal will not flow in a consistentstream and may spray out of the nozzle, resulting incasting defects from oxidation, air entrapment anderosion of the pouring cup by the metal stream.The use of VAPEX cross bore nozzles improves theintegrity and consistency of the metal flow into themould.Gas diffusersThe technology associated with purging of molteniron and steel with inert gasses is becomingincreasingly important as the demands on castingintegrity continue to rise. The purging process istypically undertaken in the induction furnace or thetreatment and pouring ladles, and generates manybenefits including:• Reduction in scrap rate• Improved quality of castings• Reduction in pin holing• Removal of inclusions• Reduction in gas content• Temperature homogenization• Distribution of alloying agents and de-oxidantsTo facilitate the optimum purging process, gasdiffusers are available in a range of materials andshapes.VAPEX cross bore nozzlesMetal stream from a crossbore nozzleBottom pour ladle readyfor useGas diffusers available in arange of shapes7