Industrial brushes - Brush Research Manufacturing

Industrial brushes - Brush Research Manufacturing

Industrial brushes - Brush Research Manufacturing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

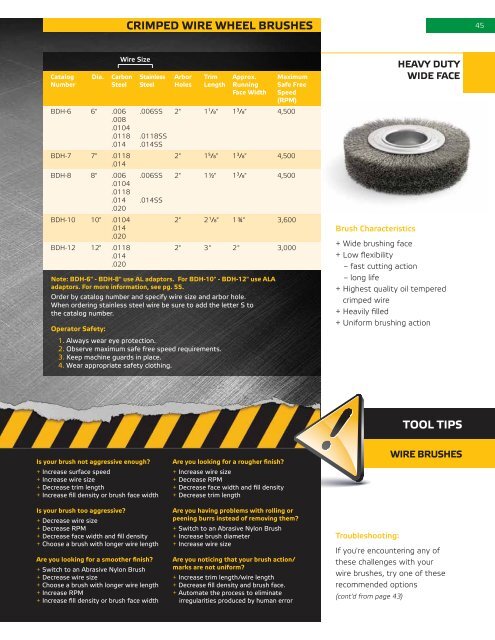

crimped wire wheel <strong>brushes</strong>45CatalogNumberDia.CarbonSteelBDH-6 6" .006.008.0104.0118.014BDH-7 7" .0118.014BDH-8 8" .006.0104.0118.014.020BDH-10 10" .0104.014.020BDH-12 12" .0118.014.020Wire SizeStainlessSteel.006SS.0118SS.014SS.006SS.014SSArborHolesTrimLengthApprox.RunningFace WidthMaximumSafe FreeSpeed(RPM)2" 1 1 /8" 1 3 /8" 4,5002" 1 5 /8" 1 3 /8" 4,5002" 1½" 1 3 /8" 4,5002" 2 1 /8" 1¾" 3,6002" 3" 2" 3,000Note: BDH-6" - BDH-8" use AL adaptors. For BDH-10" - BDH-12" use ALAadaptors. For more information, see pg. 55.Order by catalog number and specify wire size and arbor hole.When ordering stainless steel wire be sure to add the letter S tothe catalog number.Operator Safety:1. Always wear eye protection.2. Observe maximum safe free speed requirements.3. Keep machine guards in place.4. Wear appropriate safety clothing.<strong>Brush</strong> Characteristicsheavy dutywide face+ Wide brushing face+ Low flexibility– fast cutting action– long life+ Highest quality oil temperedcrimped wire+ Heavily filled+ Uniform brushing actionTOOL TIPSIs your brush not aggressive enough?+ Increase surface speed+ Increase wire size+ Decrease trim length+ Increase fill density or brush face widthIs your brush too aggressive?+ Decrease wire size+ Decrease RPM+ Decrease face width and fill density+ Choose a brush with longer wire lengthAre you looking for a smoother finish?+ Switch to an Abrasive Nylon <strong>Brush</strong>+ Decrease wire size+ Choose a brush with longer wire length+ Increase RPM+ Increase fill density or brush face widthAre you looking for a rougher finish?+ Increase wire size+ Decrease RPM+ Decrease face width and fill density+ Decrease trim lengthAre you having problems with rolling orpeening burrs instead of removing them?+ Switch to an Abrasive Nylon <strong>Brush</strong>+ Increase brush diameter+ Increase wire sizeAre you noticing that your brush action/marks are not uniform?+ Increase trim length/wire length+ Decrease fill density and brush face.+ Automate the process to eliminateirregularities produced by human errorTroubleshooting:WIRE BRUSHESIf you're encountering any ofthese challenges with yourwire <strong>brushes</strong>, try one of theserecommended options(cont'd from page 43)