AKROMID® S brochure A4 - AKRO-PLASTIC GmbH

AKROMID® S brochure A4 - AKRO-PLASTIC GmbH

AKROMID® S brochure A4 - AKRO-PLASTIC GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

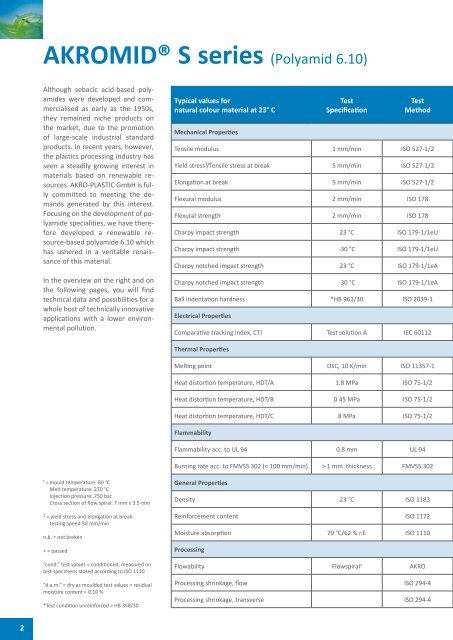

<strong>AKRO</strong>MID® S series (Polyamid 6.10)Although sebacic acid-based polyamideswere developed and commercialisedas early as the 1950s,they remained niche products onthe market, due to the promotionof large-scale industrial standardproducts. In recent years, however,the plastics processing industry hasseen a steadily growing interest inmaterials based on renewable resources.<strong>AKRO</strong>-<strong>PLASTIC</strong> <strong>GmbH</strong> is fullycommitted to meeting the demandsgenerated by this interest.Focusing on the development of polyamidespecialities, we have thereforedeveloped a renewable resource-basedpolyamide 6.10 whichhas ushered in a veritable renaissanceof this material.In the overview on the right and onthe following pages, you will findtechnical data and possibilities for awhole host of technically innovativeapplications with a lower environmentalpollution.Typical values fornatural colour material at 23° CMechanical PropertiesTestSpecificationTestMethodTensile modulus 1 mm/min ISO 527-1/2Yield stress²/Tensile stress at break 5 mm/min ISO 527-1/2Elongation at break 5 mm/min ISO 527-1/2Flexural modulus 2 mm/min ISO 178Flexural strength 2 mm/min ISO 178Charpy impact strength 23 °C ISO 179-1/1eUCharpy impact strength -30 °C ISO 179-1/1eUCharpy notched impact strength 23 °C ISO 179-1/1eACharpy notched impact strength -30 °C ISO 179-1/1eABall indentation hardness *HB 961/30 ISO 2039-1Electrical PropertiesComparative tracking index, CTI Test solution A IEC 60112Thermal PropertiesMelting point DSC, 10 K/min ISO 11357-1Heat distortion temperature, HDT/A 1.8 MPa ISO 75-1/2Heat distortion temperature, HDT/B 0.45 MPa ISO 75-1/2Heat distortion temperature, HDT/C 8 MPa ISO 75-1/2FlammabilityFlammability acc. to UL 94 0.8 mm UL 94Burning rate acc. to FMVSS 302 (< 100 mm/min) > 1 mm thickness FMVSS 302¹ = mould temperature: 80 °CMelt temperature: 270 °CInjection pressure: 750 barCross section of flow spiral: 7 mm x 3.5 mm² = yield stress and elongation at break:testing speed 50 mm/minn.b. = not broken+ = passed“cond.” test values = conditioned, measured ontest specimens stored according to ISO 1110“d.a.m.” = dry as moulded test values = residualmoisture content < 0.10 %*Test condition unreinforced = HB 358/30General PropertiesDensity 23 °C ISO 1183Reinforcement content ISO 1172Moisture absorption 70 °C/62 % r.F. ISO 1110ProcessingFlowability Flowspiral1 <strong>AKRO</strong>Processing shrinkage, flow ISO 294-4Processing shrinkage, transverse ISO 294-42