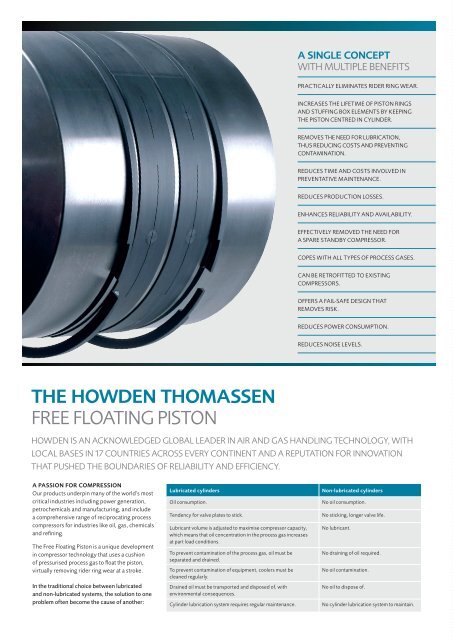

A SINGLE CONCEPTWITH MULTIPLE BENEFITSPRACTICALLY ELIMINATES RIDER RING WEAR.INCREASES THE LIFETIME OF PISTON RINGSAND STUFFING BOX ELEMENTS BY KEEPINGTHE PISTON CENTRED IN CYLINDER.REMOVES THE NEED FOR LUBRICATION,THUS REDUCING COSTS AND PREVENTINGCONTAMINATION.REDUCES TIME AND COSTS INVOLVED INPREVENTATIVE MAINTENANCE.REDUCES PRODUCTION LOSSES.ENHANCES RELIABILITY AND AVAILABILITY.EFFECTIVELY REMOVED THE NEED FORA SPARE STANDBY COMPRESSOR.COPES WITH ALL TYPES OF PROCESS GASES.CAN BE RETROFITTED TO EXISTINGCOMPRESSORS.OFFERS A FAIL-SAFE DESIGN THATREMOVES RISK.REDUCES POWER CONSUMPTION.REDUCES NOISE LEVELS.THE HOWDEN THOMASSENFREE FLOATING PISTONHOWDEN IS AN ACKNOWLEDGED GLOBAL LEADER IN AIR AND GAS HANDLING TECHNOLOGY, WITHLOCAL BASES IN 17 COUNTRIES ACROSS EVERY CONTINENT AND A REPUTATION FOR INNOVATIONTHAT PUSHED THE BOUNDARIES OF RELIABILITY AND EFFICIENCY.A PASSION FOR COMPRESSIONOur products underpin many of the world’s mostcritical industries including power generation,petrochemicals and manufacturing, and includea comprehensive range of reciprocating processcompressors for industries like oil, gas, chemicalsand refining.The Free Floating Pis<strong>to</strong>n is a unique developmentin compressor technology that uses a cushionof pressurised process gas <strong>to</strong> float the pis<strong>to</strong>n,virtually removing rider ring wear at a stroke.In the traditional choice between lubricatedand non-lubricated systems, the solution <strong>to</strong> oneproblem often become the cause of another:Lubricated cylindersOil consumption.Tendency for valve plates <strong>to</strong> stick.Lubricant volume is adjusted <strong>to</strong> maximise compressor capacity,which means that oil concentration in the process gas increasesat part load conditions.To prevent contamination of the process gas, oil must beseparated and drained.To prevent contamination of equipment, coolers must becleaned regularly.Drained oil must be transported and disposed of, withenvironmental consequences.Cylinder lubrication system requires regular maintenance.Non-lubricated cylindersNo oil consumption.No sticking, longer valve life.No lubricant.No draining of oil required.No oil contamination.No oil <strong>to</strong> dispose of.No cylinder lubrication system <strong>to</strong> maintain.

HOW IT WORKS^VIRTUALLY FRICTION-FREE SUPPORTAs it travels in the cylinder, the FFPis carried by a thin cushion of processgas. While the concept is simple, theimplementation demands the higheststandards of precision engineering.^ACCURATELY DIRECTED GAS FLOWPressure-sensitive valves have beenadded <strong>to</strong> the face of the pis<strong>to</strong>n. Duringthe compression stroke, these valves arepushed open <strong>to</strong> allow the interior of thepis<strong>to</strong>n <strong>to</strong> flood with process gas underhigh pressure. The gas is then forced outthrough flow nozzles integrated in<strong>to</strong> thebot<strong>to</strong>m of the rider rings <strong>to</strong> form a filmof pressurised gas, around 10–50 micronsdeep, that supports the weight ofthe pis<strong>to</strong>n.^FAIL-SAFE OPERATIONThe lower surface of the rider rings carrya machined profile that ensures the gas isdistributed accurately <strong>to</strong> create a bearinglayer, and the rider rings have beenrelocated <strong>to</strong> sit between the pis<strong>to</strong>n rings,which thus form a sealed enclosure.Contact between the rider ring and thecylinder lining is effectively reduced <strong>to</strong>zero, and as long as there is pressure inthe system the cushion layer is maintained,providing a fail-safe mechanism in theevent of problems arising elsewhere.Special designed non return valvesflow nozzlesA RADICAL RESPONSE TO THEDEMANDS OF MODERN INDUSTRYAs process requirements become ever morecritical and environmental constraints morestringent, oil-free compressor cylinders arebecoming increasingly prevalent. Withoutlubrication, however, conditions within thecylinder can accelerate the wear so drasticallythat running time between maintenance s<strong>to</strong>ps maybe reduced <strong>to</strong> a few hundred hours. At the sametime, commercial pressures increasingly demanduninterrupted running of three years or more.Our engineers under<strong>to</strong>ok a radical rethink of thefundamental principles of compressor design,investigating the principles and possibilities ofeach component. The outcome, the FFP isan elegant and ingenious method of virtuallyeliminating rider ring wear. It uses pressurisedprocess gas <strong>to</strong> provide a cushion that lifts thepis<strong>to</strong>n clear of the cylinder lining, so that the riderring is only in contact with the cylinder during thebrief start up and shut down periods. The volumeof gas required is extremely small – less than oneper cent of the cylinder capacity – andcompensated for in the cylinder design,so there is no loss of overall capacity.The FFP brings all the advantages of oil-freeoperation without the usual drawbacks, whileavoiding the expensive and time-consumingcomplications introduced by of lubricationsystems. It already has more than ten yearsproven performance in some of the mostdemanding industrial situations.RESULTS THAT QUICKLYREPAY INVESTMENTAfter successfully completing a rigorous seriesof in-house static and dynamic pro<strong>to</strong>type testing,we worked in partnership with a cus<strong>to</strong>mer <strong>to</strong>pilot the system on-site in a heavy duty hydrogencompressor. This first installation has now beenrunning without problems, with only minimalbreaks for planned maintenance, since 1998.Almost 250 FFP systems have been installed <strong>to</strong>date, and the data accumulated over ten years ofindustrial experience shows that rider ring wearis reduced <strong>to</strong> practically zero, repairs are minimaland reliability is excellent.ELIMINATE RIDER RING WEAR PROBLEMS, AND THEWEAKEST POINT BECOMES ONE OF THE STRONGEST.