Core Bits - Norton Construction Products

Core Bits - Norton Construction Products

Core Bits - Norton Construction Products

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

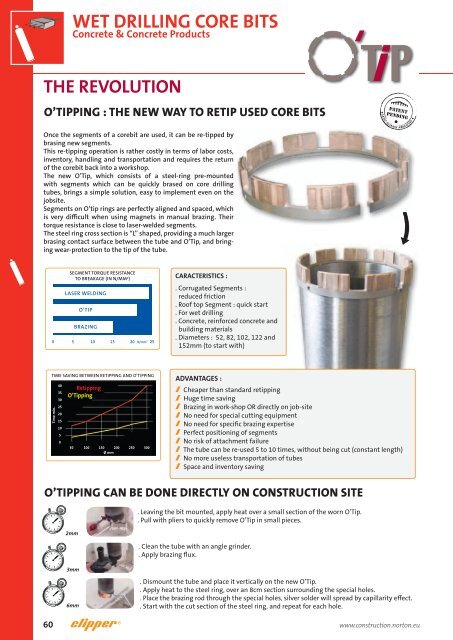

WET DRILLING CORE BITSConcrete & Concrete <strong>Products</strong>THE REVOLUTIONO’TIPPING : THE NEW WAY TO RETIP USED CORE BITSOnce the segments of a corebit are used, it can be re-tipped bybrasing new segments.This re-tipping operation is rather costly in terms of labor costs,inventory, handling and transportation and requires the returnof the corebit back into a workshop.The new O’Tip, which consists of a steel-ring pre-mountedwith segments which can be quickly brased on core drillingtubes, brings a simple solution, easy to implement even on thejobsite.Segments on O’tip rings are perfectly aligned and spaced, whichis very difficult when using magnets in manual brazing. Theirtorque resistance is close to laser-welded segments.The steel ring cross section is “L” shaped, providing a much largerbrasing contact surface between the tube and O’Tip, and bringingwear-protection to the tip of the tube.SEGMENT TORQUE RESISTANCETO BREAKAGE (IN N/MM²)LASER WELDINGO’TIPBRAZING0 5 10 15 20 N/mm 2 25CARACTERISTICS :. Corrugated Segments :reduced friction. Roof top Segment : quick start. For wet drilling. Concrete, reinforced concrete andbuilding materials. Diameters : 52, 82, 102, 122 and152mm (to start with)TIME SAVING BETWEEN RETIPPING AND O’TIPPINGTime min.4035302520151050RetippingO’Tipping50 100 150 200 250 300Ø mmADVANTAGES :Cheaper than standard retippingHuge time savingBrazing in work-shop OR directly on job-siteNo need for special cutting equipmentNo need for specific brazing expertisePerfect positioning of segmentsNo risk of attachment failureThe tube can be re-used 5 to 10 times, without being cut (constant length)No more useless transportation of tubesSpace and inventory savingO’TIPPING CAN BE DONE DIRECTLY ON CONSTRUCTION SITE2mm3mm. Leaving the bit mounted, apply heat over a small section of the worn O’Tip.. Pull with pliers to quickly remove O’Tip in small pieces.. Clean the tube with an angle grinder.. Apply brazing flux.6mm. Dismount the tube and place it vertically on the new O’Tip.. Apply heat to the steel ring, over an 8cm section surrounding the special holes.. Place the brazing rod through the special holes, silver solder will spread by capillarity effect.. Start with the cut section of the steel ring, and repeat for each hole.60www.construction.norton.eu