Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

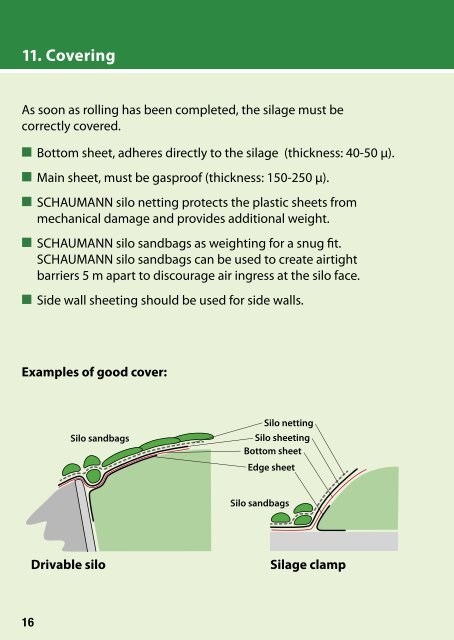

11. Covering12. Silo faceAs soon as rolling has been completed, the silage must becorrectly covered.n Bottom sheet, adheres directly to the silage (thickness: 40-50 µ).n Main sheet, must be gasproof (thickness: 150-250 µ).n SCHAUMANN silo netting protects the plastic sheets frommechanical damage and provides additional weight.n SCHAUMANN silo sandbags as weighting for a snug fit.SCHAUMANN silo sandbags can be used to create airtightbarriers 5 m apart to discourage air ingress at the silo face.n Side wall sheeting should be used for side walls.Examples of good cover:Silo sandbagsSilo nettingSilo sheetingBottom sheetEdge sheetSilo sandbagsThe minimum removal rate to avoid heating up should be 1.5 mper week in winter and 2.5 m per week in summer. The removaltechnique should be designed to do as little damage as possibleto the exposed face and to minimise air ingress.Effects of removal technique on silo face temperature(after 20 hours, 20 cm behind the face)Temperature (°C)2322212019181716Block cutterPreventing heating upn Create summer silos with a smaller silo face.n Do not have the face of the silo facing into the prevailing wind.n Leave the silo sheet in place until near the time of silage removal.n Calculate the silo length and removal rate according to the herd size.n Optimise the removal technique.Air flow in an open siloCutting plate withmovable knives fixed knives<strong>Silage</strong> cutterTined bucketRotary cutterAtmospheric oxygenSource: Steinhöfel and Pahlke, 2005Drivable silo<strong>Silage</strong> clampReserveheatCO 2H 2 O16Note: to avoid heating up, the silo face should be adaptedto the requirements of the farm.17