Poly(lactic acid) fibers - Jim Lunt LLC

Poly(lactic acid) fibers - Jim Lunt LLC

Poly(lactic acid) fibers - Jim Lunt LLC

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

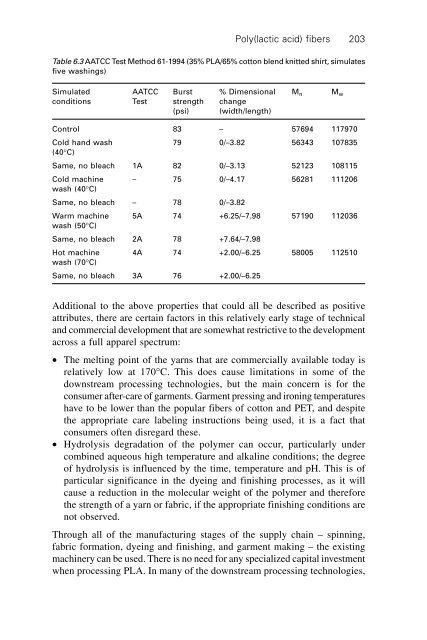

<strong>Poly</strong>(<strong>lactic</strong> <strong>acid</strong>) <strong>fibers</strong> 203Table 6.3 AATCC Test Method 61-1994 (35% PLA/65% cotton blend knitted shirt, simulatesfive washings)Simulated AATCC Burst % Dimensional M n M wconditions Test strength change(psi) (width/length)Control 83 – 57694 117970Cold hand wash 79 0/–3.82 56343 107835(40∞C)Same, no bleach 1A 82 0/–3.13 52123 108115Cold machine – 75 0/–4.17 56281 111206wash (40∞C)Same, no bleach – 78 0/–3.82Warm machine 5A 74 +6.25/–7.98 57190 112036wash (50∞C)Same, no bleach 2A 78 +7.64/–7.98Hot machine 4A 74 +2.00/–6.25 58005 112510wash (70∞C)Same, no bleach 3A 76 +2.00/–6.25Additional to the above properties that could all be described as positiveattributes, there are certain factors in this relatively early stage of technicaland commercial development that are somewhat restrictive to the developmentacross a full apparel spectrum:∑ The melting point of the yarns that are commercially available today isrelatively low at 170∞C. This does cause limitations in some of thedownstream processing technologies, but the main concern is for theconsumer after-care of garments. Garment pressing and ironing temperatureshave to be lower than the popular <strong>fibers</strong> of cotton and PET, and despitethe appropriate care labeling instructions being used, it is a fact thatconsumers often disregard these.∑ Hydrolysis degradation of the polymer can occur, particularly undercombined aqueous high temperature and alkaline conditions; the degreeof hydrolysis is influenced by the time, temperature and pH. This is ofparticular significance in the dyeing and finishing processes, as it willcause a reduction in the molecular weight of the polymer and thereforethe strength of a yarn or fabric, if the appropriate finishing conditions arenot observed.Through all of the manufacturing stages of the supply chain – spinning,fabric formation, dyeing and finishing, and garment making – the existingmachinery can be used. There is no need for any specialized capital investmentwhen processing PLA. In many of the downstream processing technologies,