Intelligent PID Controller for Real Time Automation of Microwave ...

Intelligent PID Controller for Real Time Automation of Microwave ...

Intelligent PID Controller for Real Time Automation of Microwave ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

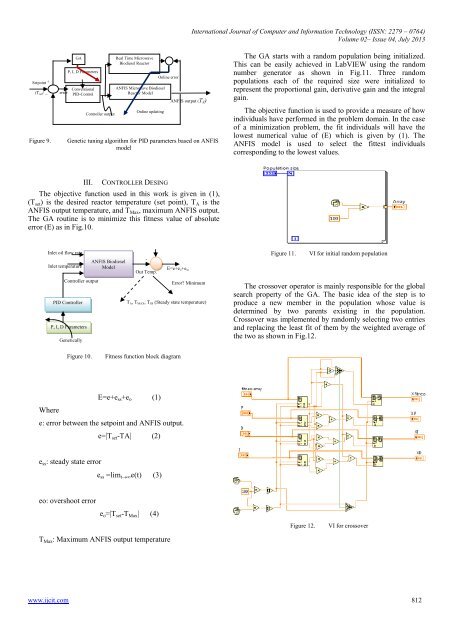

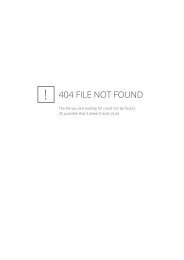

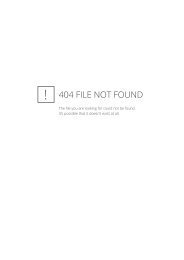

International Journal <strong>of</strong> Computer and In<strong>for</strong>mation Technology (ISSN: 2279 – 0764)Volume 02– Issue 04, July 2013Setpoint +(Tset) _Figure 9.errorGAP, I, D ParametersConventional<strong>PID</strong>-Control<strong>Controller</strong> output<strong>Real</strong> <strong>Time</strong> <strong>Microwave</strong>Biodiesel ReactorANFIS <strong>Microwave</strong> BiodieselReactor ModelOnline updatingOnline errorGenetic tuning algorithm <strong>for</strong> <strong>PID</strong> parameters based on ANFISmodel_ANFIS output (T A)The GA starts with a random population being initialized.This can be easily achieved in LabVIEW using the randomnumber generator as shown in Fig.11. Three randompopulations each <strong>of</strong> the required size were initialized torepresent the proportional gain, derivative gain and the integralgain.The objective function is used to provide a measure <strong>of</strong> howindividuals have per<strong>for</strong>med in the problem domain. In the case<strong>of</strong> a minimization problem, the fit individuals will have thelowest numerical value <strong>of</strong> (E) which is given by (1). TheANFIS model is used to select the fittest individualscorresponding to the lowest values.III.CONTROLLER DESINGThe objective function used in this work is given in (1),(T set ) is the desired reactor temperature (set point), T A is theANFIS output temperature, and T Max , maximum ANFIS output.The GA routine is to minimize this fitness value <strong>of</strong> absoluteerror (E) as in Fig.10.Inlet oil flow rateInlet temperature<strong>Controller</strong> output<strong>PID</strong> <strong>Controller</strong>P, I, D ParametersGeneticallyANFIS BiodieselModel-Out Temp.E=e+eo+essError? MinimumTA, TMAX, TSS (Steady state temperature)Figure 11.VI <strong>for</strong> initial random populationThe crossover operator is mainly responsible <strong>for</strong> the globalsearch property <strong>of</strong> the GA. The basic idea <strong>of</strong> the step is toproduce a new member in the population whose value isdetermined by two parents existing in the population.Crossover was implemented by randomly selecting two entriesand replacing the least fit <strong>of</strong> them by the weighted average <strong>of</strong>the two as shown in Fig.12.Figure 10.Fitness function block diagramE=e+e ss +e o (1)Wheree: error between the setpoint and ANFIS output.e=|T set -TA| (2)e ss : steady state errore ss =lim t e(t) (3)eo: overshoot errore o =|T set -T Max | (4)Figure 12.VI <strong>for</strong> crossoverT Max : Maximum ANFIS output temperaturewww.ijcit.com 812