If Preferred -- Download The Entire Booklet - Spears Manufacturing ...

If Preferred -- Download The Entire Booklet - Spears Manufacturing ...

If Preferred -- Download The Entire Booklet - Spears Manufacturing ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

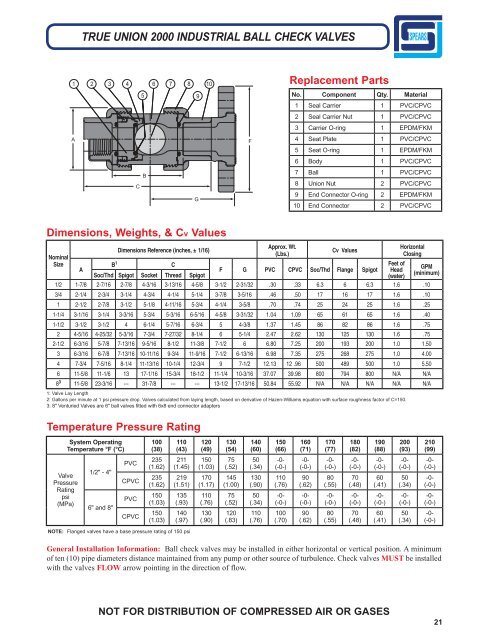

TRUE UNION 2000 INDUSTRIAL BALL CHECK VALVESDimensions, Weights, & Cv ValuesNominalSizeDimensions Reference (inches, ± 1/16)Temperature Pressure RatingApprox. Wt.(Lbs.)Replacement PartsNo. Component Qty. Material1 Seal Carrier 1 PVC/CPVC2 Seal Carrier Nut 1 PVC/CPVC3 Carrier O-ring 1 EPDM/FKM4 Seat Plate 1 PVC/CPVC5 Seat O-ring 1 EPDM/FKM6 Body 1 PVC/CPVC7 Ball 1 PVC/CPVC8 Union Nut 2 PVC/CPVC9 End Connector O-ring 2 EPDM/FKM10 End Connector 2 PVC/CPVCCv Values1: Valve Lay Length2: Gallons per minute at 1 psi pressure drop. Valves calculated from laying length, based on derivative of Hazen-Williams equation with surface roughness factor of C=150.3: 8" Venturied Valves are 6" ball valves fitted with 6x8 end connector adaptersHorizontalClosingAB 1CFeet ofF G PVC CPVC Soc/Thd Flange Spigot HeadSoc/Thd Spigot Socket Thread Spigot(water)1/2 1-7/8 2-7/16 2-7/8 4-3/16 3-13/16 4-5/8 3-1/2 2-31/32 .30 .33 6.3 6 6.3 1.6 .103/4 2-1/4 2-3/4 3-1/4 4-3/4 4-1/4 5-1/4 3-7/8 3-5/16 .46 .50 17 16 17 1.6 .101 2-1/2 2-7/8 3-1/2 5-1/8 4-11/16 5-3/4 4-1/4 3-5/8 .70 .74 25 24 25 1.6 .251-1/4 3-1/16 3-1/4 3-3/16 5-3/4 5-3/16 6-5/16 4-5/8 3-31/32 1.04 1.09 65 61 65 1.6 .401-1/2 3-1/2 3-1/2 4 6-1/4 5-7/16 6-3/4 5 4-3/8 1.37 1.45 86 82 86 1.6 .752 4-5/16 4-25/32 5-3/16 7-3/4 7-27/32 8-1/4 6 5-1/4 2.47 2.62 130 125 130 1.6 .752-1/2 6-3/16 5-7/8 7-13/16 9-5/16 8-1/2 11-3/8 7-1/2 6 6.80 7.25 200 193 200 1.0 1.503 6-3/16 6-7/8 7-13/16 10-11/16 9-3/4 11-9/16 7-1/2 6-13/16 6.98 7.35 275 268 275 1.0 4.004 7-3/4 7-5/16 8-1/4 11-13/16 10-1/4 12-3/4 9 7-1/2 12.13 12 .96 500 489 500 1.0 5.506 11-5/8 11-1/6 13 17-1/16 15-3/4 18-1/2 11-1/4 10-3/16 37.07 39.98 800 794 800 N/A N/A8 3 11-5/8 23-3/16 --- 31-7/8 --- --- 13-1/2 17-13/16 50.84 55.92 N/A N/A N/A N/A N/AGPM(minimum)System OperatingTemperature °F (°C)100(38)110(43)120(49)130(54)140(60)150(66)160(71)170(77)180(82)190(88)200(93)210(99)ValvePressureRatingpsi(MPa)1/2" - 4"6" and 8"PVCCPVCPVCCPVC235(1.62)235(1.62)150(1.03)150(1.03)211(1.45)219(1.51)135(.93)140(.97)150(1.03)170(1.17)110(.76)130(.90)75(.52)145(1.00)75(.52)120(.83)50(.34)130(.90)50(.34)110(.76)-0-(-0-)110(.76)-0-(-0-)100(.70)-0-(-0-)90(.62)-0-(-0-)90(.62)-0-(-0-)80(.55)-0-(-0-)80(.55)-0-(-0-)70(.48)-0-(-0-)70(.48)-0-(-0-)60(.41)-0-(-0-)60(.41)-0-(-0-)50(.34)-0-(-0-)50(.34)-0-(-0-)-0-(-0-)-0-(-0-)-0-(-0-)NOTE: Flanged valves have a base pressure rating of 150 psiGeneral Installation Information: Ball check valves may be installed in either horizontal or vertical position. A minimumof ten (10) pipe diameters distance maintained from any pump or other source of turbulence. Check valves MUST be installedwith the valves FLOW arrow pointing in the direction of flow.NOT FOR DISTRIBUTION OF COMPRESSED AIR OR GASES21