Contact us - ULMA Packaging

Contact us - ULMA Packaging

Contact us - ULMA Packaging

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

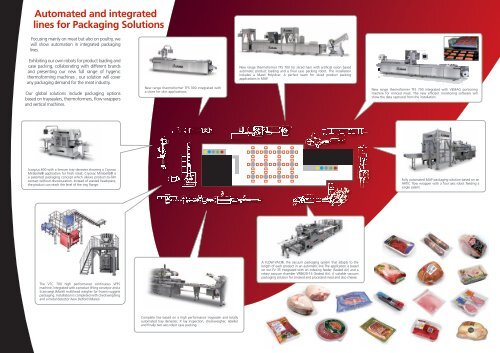

Automated and integrated<br />

lines for <strong>Packaging</strong> Solutions<br />

Foc<strong>us</strong>ing mainly on meat but also on poultry, we<br />

will show automation in integrated packaging<br />

lines.<br />

Exhibiting our own robots for product loading and<br />

case packing, collaborating with different brands<br />

and presenting our new full range of hygenic<br />

thermoforming machines , our solution will cover<br />

any packaging demand for the meat ind<strong>us</strong>try.<br />

Our global solutions include packaging options<br />

based on traysealers, thermoformers, flow wrappers<br />

and vertical machines.<br />

Scorpi<strong>us</strong> 600 with a Sercom tray denester showing a Cryovac<br />

Mirabella® application for fresh meat. Cryovac Mirabella® is<br />

a patented packaging concept which allows product-to-film<br />

contact without discolouration. Instead of wasted headspace,<br />

the product can reach the level of the tray flange.<br />

The VTC 700 high performance continuo<strong>us</strong> VFFS<br />

machine, integrated with a product lifting conveyor and a<br />

Scanvaegt (Marel) multihead weigher for frozen nuggets<br />

packaging. Installation is completed with checkweighing<br />

and a metal detector Aew Delford (Marel).<br />

New range thermoformer TFS 300 integrated with<br />

a slicer for skin applications.<br />

Complete line based on a high performance traysealer and totally<br />

automated tray denester, X ray inspection, checkweigher, labeller<br />

and finally two axis robot case packing.<br />

New range thermoformer TFS 700 for sliced ham with artificial vision based<br />

automatic product loading and a final case packing robot. The installation<br />

includes a Marel Polyslicer. A perfect team for sliced product packing<br />

applications in MAP.<br />

A FLOW-VAC®, the vacuum packaging system that adapts to the<br />

length of each product in an automatic line.The application is based<br />

on our FV 35 integrated with an indexing feeder (Sealed Air) and a<br />

rotary vacuum chamber VR8620-14 (Sealed Air). A suitable vacuum<br />

packaging solution for smoked and processed meat and also cheese.<br />

New range thermoformer TFS 700 integrated with VEMAG portioning<br />

machine for minced meat. The new efficient monitoring software will<br />

show the data captured from the installation.<br />

Fully automated MAP packaging solution based on an<br />

ARTIC flow wrapper with a four axis robot feeding a<br />

single salami.