Pipe Fittings & Port Adapters - LSR Distribuidor

Pipe Fittings & Port Adapters - LSR Distribuidor

Pipe Fittings & Port Adapters - LSR Distribuidor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

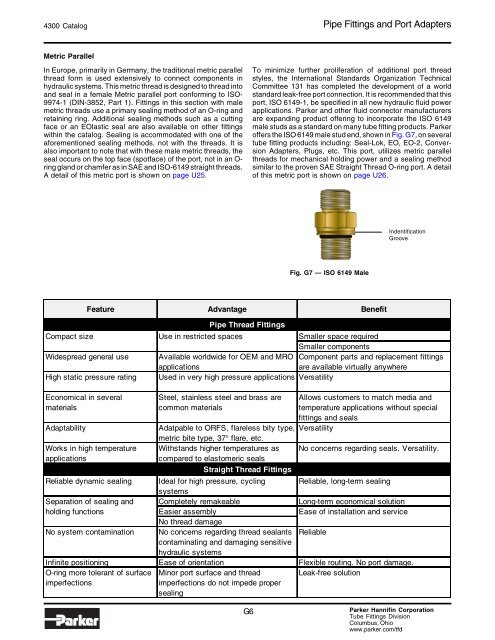

4300 Catalog <strong>Pipe</strong> <strong>Fittings</strong> and <strong>Port</strong> <strong>Adapters</strong>Metric ParallelIn Europe, primarily in Germany, the traditional metric parallelthread form is used extensively to connect components inhydraulic systems. This metric thread is designed to thread intoand seal in a female Metric parallel port conforming to ISO-9974-1 (DIN-3852, Part 1). <strong>Fittings</strong> in this section with malemetric threads use a primary sealing method of an O-ring andretaining ring. Additional sealing methods such as a cuttingface or an EOlastic seal are also available on other fittingswithin the catalog. Sealing is accommodated with one of theaforementioned sealing methods, not with the threads. It isalso important to note that with these male metric threads, theseal occurs on the top face (spotface) of the port, not in an O-ring gland or chamfer as in SAE and ISO-6149 straight threads.A detail of this metric port is shown on page U25.To minimize further proliferation of additional port threadstyles, the International Standards Organization TechnicalCommittee 131 has completed the development of a worldstandard leak-free port connection. It is recommended that thisport, ISO 6149-1, be specified in all new hydraulic fluid powerapplications. Parker and other fluid connector manufacturersare expanding product offering to incorporate the ISO 6149male studs as a standard on many tube fitting products. Parkeroffers the ISO 6149 male stud end, shown in Fig. G7, on severaltube fitting products including: Seal-Lok, EO, EO-2, Conversion<strong>Adapters</strong>, Plugs, etc. This port, utilizes metric parallelthreads for mechanical holding power and a sealing methodsimilar to the proven SAE Straight Thread O-ring port. A detailof this metric port is shown on page U26.IndentificationGrooveFig. G7 — ISO 6149 MaleFeature Advantage BenefitCompact sizeWidespread general useHigh static pressure rating<strong>Pipe</strong> Thread <strong>Fittings</strong>Use in restricted spacesSmaller space requiredSmaller componentsAvailable worldwide for OEM and MRO Component parts and replacement fittingsapplicationsare available virtually anywhereUsed in very high pressure applications VersatilityEconomical in severalmaterialsAdaptabilityWorks in high temperatureapplicationsSteel, stainless steel and brass arecommon materialsAdatpable to ORFS, flareless bity type,metric bite type, 37° flare, etc.Withstands higher temperatures ascompared to elastomeric sealsAllows customers to match media andtemperature applications without specialfittings and sealsVersatilityNo concerns regarding seals. Versatility.Straight Thread <strong>Fittings</strong>Reliable dynamic sealing Ideal for high pressure, cycling Reliable, long-term sealingsystemsSeparation of sealing and Completely remakeableLong-term economical solutionholding functionsEasier assemblyNo thread damageEase of installation and serviceNo system contamination No concerns regarding thread sealants Reliablecontaminating and damaging sensitivehydraulic systemsInfinite positioning Ease of orientation Flexible routing. No port damage.O-ring more tolerant of surfaceimperfectionsMinor port surface and threadimperfections do not impede propersealingLeak-free solutionG6Parker Hannifin CorporationTube <strong>Fittings</strong> DivisionColumbus, Ohiowww.parker.com/tfd