Improving Performance - Billet Casting Improving ... - Pyrotek

Improving Performance - Billet Casting Improving ... - Pyrotek

Improving Performance - Billet Casting Improving ... - Pyrotek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Page 10<br />

<strong>Improving</strong> <strong>Performance</strong> - <strong>Billet</strong> <strong>Casting</strong><br />

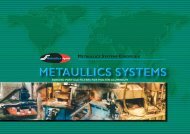

improve their profitability. <strong>Pyrotek</strong> is the<br />

exclusive distributor for the world’s largest<br />

supplier of the highest quality BN coatings,<br />

ZYP ® Coatings Inc. and stand ready to assist<br />

Figure 25 - Wise Chem Safety Coating with conversion techniques<br />

and practices to maximize<br />

the performance of their<br />

release coatings.<br />

<strong>Pyrotek</strong><br />

has several<br />

integrated<br />

materials to<br />

ensure its<br />

customer’s<br />

billet casting<br />

process is<br />

optimized to<br />

its maximum<br />

potential.<br />

Joe Roberts<br />

global Market<br />

Development<br />

Manager,<br />

Safety Coatings<br />

Safety is at the forefront of<br />

practically all aluminium<br />

casthouses in the world.<br />

Whenever rust, moisture,<br />

lime (leached from concrete<br />

in the pit) and molten<br />

aluminium come into<br />

close contact, then all the<br />

hazardous conditions exist<br />

for a destructive molten<br />

metal explosion. It is<br />

imperative to monitor the<br />

steel casting equipment and<br />

casting machines for signs of<br />

rust and exposure. <strong>Casting</strong><br />

pits should be inspected periodically and<br />

recoated as needed. <strong>Pyrotek</strong> offers Wise Chem<br />

pyrotek<br />

supplement<br />

safety coatings, which have been tested and is<br />

recognised by the Aluminium Association as<br />

an effective safety coating (see Figure 25).<br />

COnCLUSiOn<br />

To summarize, in addition to maximizing<br />

casting parameters, the selection of the right<br />

system of consumables can have a major<br />

impact on a plants ability to consistently cast<br />

good quality billet. <strong>Pyrotek</strong> does not offer<br />

one single product, but has several integrated<br />

materials to ensure its customer’s billet<br />

casting process is optimized to its maximum<br />

potential. <strong>Pyrotek</strong> also provides a unique level<br />

of worldwide, in-the-plant technical support<br />

and process expertise. This combination of<br />

technical support/expertise and consistent<br />

local service enables <strong>Pyrotek</strong> customers to<br />

make the correct material selections and<br />

employ them properly, thereby deriving the<br />

best potential performances from whichever<br />

casting technology they choose to employ.<br />

For additional information on billet casting<br />

go to www.pyrotek.info/billet.