Collated Fasteners - All Fasteners

Collated Fasteners - All Fasteners

Collated Fasteners - All Fasteners

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

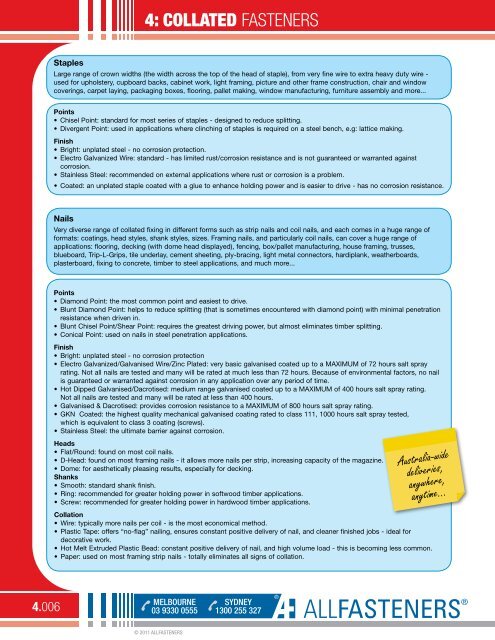

4: COLLATED FASTENERSStaplesLarge range of crown widths (the width across the top of the head of staple), from very fine wire to extra heavy duty wire -used for upholstery, cupboard backs, cabinet work, light framing, picture and other frame construction, chair and windowcoverings, carpet laying, packaging boxes, flooring, pallet making, window manufacturing, furniture assembly and more...Points• Chisel Point: standard for most series of staples - designed to reduce splitting.• Divergent Point: used in applications where clinching of staples is required on a steel bench, e.g: lattice making.Finish• Bright: unplated steel - no corrosion protection.• Electro Galvanized Wire: standard - has limited rust/corrosion resistance and is not guaranteed or warranted againstcorrosion.• Stainless Steel: recommended on external applications where rust or corrosion is a problem.• Coated: an unplated staple coated with a glue to enhance holding power and is easier to drive - has no corrosion resistance.NailsVery diverse range of collated fixing in different forms such as strip nails and coil nails, and each comes in a huge range offormats: coatings, head styles, shank styles, sizes. Framing nails, and particularly coil nails, can cover a huge range ofapplications: flooring, decking (with dome head displayed), fencing, box/pallet manufacturing, house framing, trusses,blueboard, Trip-L-Grips, tile underlay, cement sheeting, ply-bracing, light metal connectors, hardiplank, weatherboards,plasterboard, fixing to concrete, timber to steel applications, and much more...Points• Diamond Point: the most common point and easiest to drive.• Blunt Diamond Point: helps to reduce splitting (that is sometimes encountered with diamond point) with minimal penetrationresistance when driven in.• Blunt Chisel Point/Shear Point: requires the greatest driving power, but almost eliminates timber splitting.• Conical Point: used on nails in steel penetration applications.Finish• Bright: unplated steel - no corrosion protection• Electro Galvanized/Galvanised Wire/Zinc Plated: very basic galvanised coated up to a MAXIMUM of 72 hours salt sprayrating. Not all nails are tested and many will be rated at much less than 72 hours. Because of environmental factors, no nailis guaranteed or warranted against corrosion in any application over any period of time.• Hot Dipped Galvanised/Dacrotised: medium range galvanised coated up to a MAXIMUM of 400 hours salt spray rating.Not all nails are tested and many will be rated at less than 400 hours.• Galvanised & Dacrotised: provides corrosion resistance to a MAXIMUM of 800 hours salt spray rating.• GKN Coated: the highest quality mechanical galvanised coating rated to class 111, 1000 hours salt spray tested,which is equivalent to class 3 coating (screws).• Stainless Steel: the ultimate barrier against corrosion.Heads• Flat/Round: found on most coil nails.• D-Head: found on most framing nails - it allows more nails per strip, increasing capacity of the magazine.• Dome: for aesthetically pleasing results, especially for decking.Shanks• Smooth: standard shank finish.• Ring: recommended for greater holding power in softwood timber applications.• Screw: recommended for greater holding power in hardwood timber applications.Australia-widedeliveries,anywhere,anytime...Collation• Wire: typically more nails per coil - is the most economical method.• Plastic Tape: offers “no-flag” nailing, ensures constant positive delivery of nail, and cleaner finished jobs - ideal fordecorative work.• Hot Melt Extruded Plastic Bead: constant positive delivery of nail, and high volume load - this is becoming less common.• Paper: used on most framing strip nails - totally eliminates all signs of collation.4.006MELBOURNE03 9330 0555SYDNEY1300 255 327© 2011 ALLFASTENERS