Agietron Hyperspark Exact HS

Agietron Hyperspark Exact HS

Agietron Hyperspark Exact HS

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

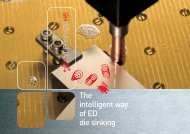

NEWGain in time andprecision with <strong>HS</strong>R = 0.05 mm<strong>HS</strong> stands for High Speed in all thegenerator’s performance ranges. Thenew <strong>Agietron</strong> <strong>Hyperspark</strong> <strong>Exact</strong> <strong>HS</strong>models in the construction sizes 2and 3 have new generator technologiesand modules at their disposalwhich bring a striking increase inpower when removing, a reduction inwear towards zero and optimum EDMresults with all workpiece materials,regardless of the electrodes’ graphitequality.FasterfinishingWith the expansion of the finishingtechnologies to include patented lowcurrent <strong>Hyperspark</strong> impulses, thefinishing, that takes up the mosttime, is reduced by 25%.Faster lifting-offmovementsWith greater acceleration and speed,as well as dynamic adaptation to themachining conditions, more EDMspeed is achieved with very low wear.Lowest wearBy means of an optimised generatormodule, pulses are formed thatadapt to the conditions prevailing inthe spark gap, thus strikingly reducingthe electrode wear, even in thecase of workpiece alloys, such asAmcolloy or Moldmax.Higher precisionand speedWith a novel process control, machiningfree of wear, perfect surfacesand highest machining speeds canbe achieved. For this, three new algorithmshave been implemented:- More precision through less wear.GEC. With Gap Energy Control, theenergy of the current pulses in thespark gap is controlled in the shortand medium term. In this way, morecurrent can be applied per contactarea, without overloading the electrode.- Good results with every type ofgraphite. APC. With Adaptive PulseControl, by fading out pulses, you ensurethat electrodes are protectedfrom degeneration and arcs, regardlessof the quality of graphite used.- More quality with less wear. PWC.With Pulse Wear Control, pulse bypulse is analysed and modulated inreal time. In this way, the wear is reducedand, in particular when usingcopper electrodes, flaws and irregularitieson the workpiece surface areavoided.ED die sinkingstandard<strong>Hyperspark</strong> <strong>HS</strong>