Teacher's notes on Art Nouveau - Sainsbury Centre for Visual Arts

Teacher's notes on Art Nouveau - Sainsbury Centre for Visual Arts

Teacher's notes on Art Nouveau - Sainsbury Centre for Visual Arts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Metal ware<br />

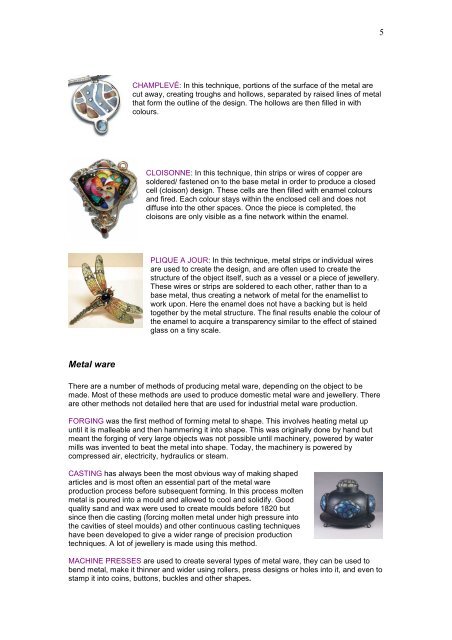

CHAMPLEVÉ: In this technique, porti<strong>on</strong>s of the surface of the metal are<br />

cut away, creating troughs and hollows, separated by raised lines of metal<br />

that <strong>for</strong>m the outline of the design. The hollows are then filled in with<br />

colours.<br />

CLOISONNE: In this technique, thin strips or wires of copper are<br />

soldered/ fastened <strong>on</strong> to the base metal in order to produce a closed<br />

cell (clois<strong>on</strong>) design. These cells are then filled with enamel colours<br />

and fired. Each colour stays within the enclosed cell and does not<br />

diffuse into the other spaces. Once the piece is completed, the<br />

clois<strong>on</strong>s are <strong>on</strong>ly visible as a fine network within the enamel.<br />

PLIQUE A JOUR: In this technique, metal strips or individual wires<br />

are used to create the design, and are often used to create the<br />

structure of the object itself, such as a vessel or a piece of jewellery.<br />

These wires or strips are soldered to each other, rather than to a<br />

base metal, thus creating a network of metal <strong>for</strong> the enamellist to<br />

work up<strong>on</strong>. Here the enamel does not have a backing but is held<br />

together by the metal structure. The final results enable the colour of<br />

the enamel to acquire a transparency similar to the effect of stained<br />

glass <strong>on</strong> a tiny scale.<br />

There are a number of methods of producing metal ware, depending <strong>on</strong> the object to be<br />

made. Most of these methods are used to produce domestic metal ware and jewellery. There<br />

are other methods not detailed here that are used <strong>for</strong> industrial metal ware producti<strong>on</strong>.<br />

FORGING was the first method of <strong>for</strong>ming metal to shape. This involves heating metal up<br />

until it is malleable and then hammering it into shape. This was originally d<strong>on</strong>e by hand but<br />

meant the <strong>for</strong>ging of very large objects was not possible until machinery, powered by water<br />

mills was invented to beat the metal into shape. Today, the machinery is powered by<br />

compressed air, electricity, hydraulics or steam.<br />

CASTING has always been the most obvious way of making shaped<br />

articles and is most often an essential part of the metal ware<br />

producti<strong>on</strong> process be<strong>for</strong>e subsequent <strong>for</strong>ming. In this process molten<br />

metal is poured into a mould and allowed to cool and solidify. Good<br />

quality sand and wax were used to create moulds be<strong>for</strong>e 1820 but<br />

since then die casting (<strong>for</strong>cing molten metal under high pressure into<br />

the cavities of steel moulds) and other c<strong>on</strong>tinuous casting techniques<br />

have been developed to give a wider range of precisi<strong>on</strong> producti<strong>on</strong><br />

techniques. A lot of jewellery is made using this method.<br />

MACHINE PRESSES are used to create several types of metal ware, they can be used to<br />

bend metal, make it thinner and wider using rollers, press designs or holes into it, and even to<br />

stamp it into coins, butt<strong>on</strong>s, buckles and other shapes.<br />

5