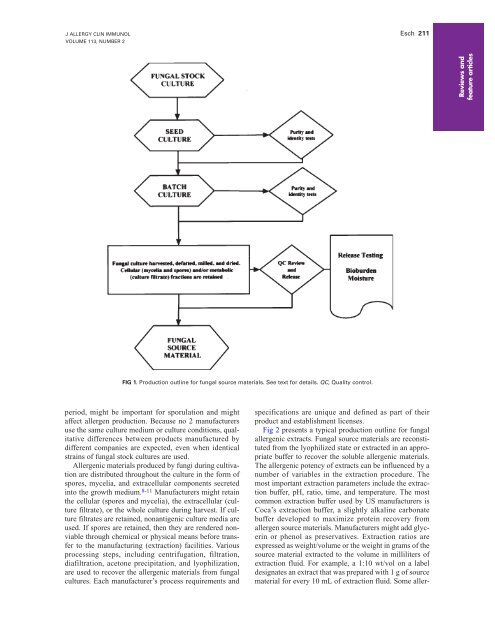

J ALLERGY CLIN IMMUNOLVOLUME 113, NUMBER 2Esch 211Reviews <strong>and</strong>feature articlesFIG 1. Production outline for fungal source materials. See text for details. QC, Quality control.period, might be important for sporulation <strong>and</strong> mightaffect allergen production. Because no 2 manufacturersuse the same culture medium or culture conditions, qualitativedifferences between products manufactured bydifferent companies are expected, even when identicalstrains of fungal stock cultures are used.<strong>Allergen</strong>ic materials produced by fungi during cultivationare distributed throughout the culture in the form ofspores, mycelia, <strong>and</strong> extracellular components secretedinto the growth medium. 8-11 Manufacturers might retainthe cellular (spores <strong>and</strong> mycelia), the extracellular (culturefiltrate), or the whole culture during harvest. If culturefiltrates are retained, nonantigenic culture media areused. If spores are retained, then they are rendered nonviablethrough chemical or physical means before transferto the manufacturing (extraction) facilities. Variousprocessing steps, including centrifugation, filtration,diafiltration, acetone precipitation, <strong>and</strong> lyophilization,are used to recover the allergenic materials from fungalcultures. Each manufacturer’s process requirements <strong>and</strong>specifications are unique <strong>and</strong> defined as part of theirproduct <strong>and</strong> establishment licenses.Fig 2 presents a typical production outline for fungalallergenic extracts. <strong>Fungal</strong> source materials are reconstitutedfrom the lyophilized state or extracted in an appropriatebuffer to recover the soluble allergenic materials.The allergenic potency of extracts can be influenced by anumber of variables in the extraction procedure. Themost important extraction parameters include the extractionbuffer, pH, ratio, time, <strong>and</strong> temperature. The mostcommon extraction buffer used by US manufacturers isCoca’s extraction buffer, a slightly alkaline carbonatebuffer developed to maximize protein recovery fromallergen source materials. Manufacturers might add glycerinor phenol as preservatives. Extraction ratios areexpressed as weight/volume or the weight in grams of thesource material extracted to the volume in milliliters ofextraction fluid. For example, a 1:10 wt/vol on a labeldesignates an extract that was prepared with 1 g of sourcematerial for every 10 mL of extraction fluid. Some aller-

212 Esch J ALLERGY CLIN IMMUNOLFEBRUARY 2004Reviews <strong>and</strong>feature articlesTABLE I. Commercially available fungal allergen extractsSpecies Synonym Species SynonymAcremonium stricturm Cephalosporium acrenomium Neurospora intermedia Monilia sitophilaAlternaria alternata Alternaria tenuis Nigrospora oryzaeApiospora montagnei Papularia Nigrospora sphaericaAspergillus fumigatusPaecilomyces variotiiAspergillus nigerPaecilomyces clavisporisAspergillus glaucusPenicillium notatumAspergillus terreusPenicillium chrysogenumAspergillus nidulansPenicillium digitatumAspergillus flavusPhoma betaeAureobasidium pullulans Pullularia pullulans Phoma herbarumBotrytis cinereaPhoma destructiveC<strong>and</strong>ida albicansPhycomyces blakesleenusC<strong>and</strong>ida tropicalis Pleospora herbarum Stemphylium herbarumChaetomium globosum Rhizopus oryzae Rhizopus arrhizusCladosporium herbarum Rhizopus stolonifer Rhizopus nigricansCladosporium sphaerospermum Hormodendrum hordei Rhodotorula mucilagnosa Rhodotorula rubraCladosporium cladosporoides Hormodendrum Saccharomyces cerevisiaecladosporoides Scopulariopsis brevicaulis Penicillium brevicaulisColletotrichum atramentarium Spondylocladium Sporotrichum pruinosum Chrysosporium pruinosumatramentariumStachybotrys chartarumCurvularia lunataStemphylium botryosumDrechslera specifera Curvularia specifera Stemphylium solaniEpicoccum nigrum Epicoccum purpurascens Stemphylium sarcinaeformeEpidermophyton floccosumStreptomyces griseusFusarium solaniSyncephalastrum racemosumFusarium moniliformeTetracoccosporium paxianumFusarium vasinfectum Fusarium oxysporum Trichoderma harzianum Trichoderma lignorumGeotrichum c<strong>and</strong>idumTrichophyton mentagrophytesGliocladium viride Gliocladium deliquescens Trichophyton rubrumGliocladium fimbriatumTrichophyton tonsuransHelminthosporium sativum Trichothecium roseum Cephalothecium roseumHelminthosporium solani Spondylocladium atrovirens Verticillium albo-atrumHypocrea rufaPuccinia graminis triticiMicrosporum canisUstilago maydisMucor circinelloides Mucor racemosus Ustilago cynodontis(formerly lusitanicus)Ustilago nudaMucor circinelloides Mucor mucedo Ustilago avenae(formerly circinelloides)Ustilago triticiMucor plumbeus Sphacelotheca cruenta Sporisorium cruentaMycogone perniciosagens are rapidly eluted from fungal source materials,whereas others might require homogenization, shaking,or long extraction times for maximum recovery. Thereexists a tradeoff between maximum allergen recovery<strong>and</strong> the increased release of nonallergenic substances <strong>and</strong>proteases, which might degrade some allergens. Manydifferent procedures have been devised to extract allergensfrom fungi, <strong>and</strong> no single process has been universallyadopted by the industry. 12The extract is clarified by means of centrifugation, filtration,or both through a series of filters of decreasingporosity. The supernatant or filtrate might undergo furtherprocessing, such as dialysis to remove low-molecular-weightnonallergenic material <strong>and</strong> the addition ofglycerin. The extract is rendered sterile by passing theextract through a sterilizing filter with a 0.2-µm porosity.The clarifying <strong>and</strong> sterilizing filters used must beshown not to adsorb allergens onto their surface <strong>and</strong> notto contribute any residual material into the product. Thesterile extract is quarantined until tested <strong>and</strong> released foradditional aseptic processing. Quality control testing ofthis sterile intermediate or bulk extract include tests forsterility, safety (toxicity in animals), pH, protein nitrogenunits, <strong>and</strong> preservative (phenol or glycerin). Thereleased bulk extract is aseptically diluted, mixed withother bulk products, or used without further processingto prepare stock concentrates, custom mixtures, or individualprescriptions for sale.COMPOSITION OF FUNGAL ALLERGENICEXTRACTS<strong>Fungal</strong> allergenic extracts are complex mixtures ofproteins, glycoproteins, polysaccharides, <strong>and</strong> other substances.The mean protein <strong>and</strong> carbohydrate concentrationsof selected fungal stock concentrates prepared by asingle manufacturer at 1:10 wt/vol are presented in TableII. At equivalent weight/volume concentrations, the proteincontent varied approximately 7-fold. All extractstested contained significantly higher concentrations ofcarbohydrate compared with protein, with the ratio rangingfrom about 5 to 25.