Seam Engineering TB

Seam Engineering TB

Seam Engineering TB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

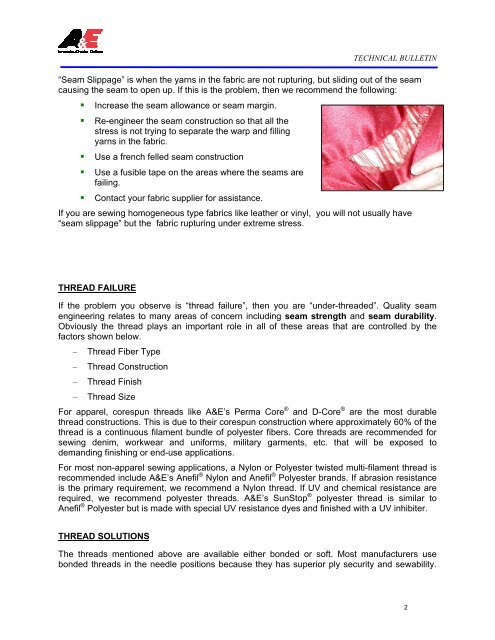

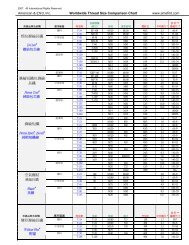

TECHNICAL BULLETIN“<strong>Seam</strong> Slippage” is when the yarns in the fabric are not rupturing, but sliding out of the seamcausing the seam to open up. If this is the problem, then we recommend the following:• Increase the seam allowance or seam margin.• Re-engineer the seam construction so that all thestress is not trying to separate the warp and fillingyarns in the fabric.• Use a french felled seam construction• Use a fusible tape on the areas where the seams arefailing.• Contact your fabric supplier for assistance.If you are sewing homogeneous type fabrics like leather or vinyl, you will not usually have“seam slippage” but the fabric rupturing under extreme stress.THREAD FAILUREIf the problem you observe is “thread failure”, then you are “under-threaded”. Quality seamengineering relates to many areas of concern including seam strength and seam durability.Obviously the thread plays an important role in all of these areas that are controlled by thefactors shown below.– Thread Fiber Type– Thread Construction– Thread Finish– Thread SizeFor apparel, corespun threads like A&E’s Perma Core ® and D-Core ® are the most durablethread constructions. This is due to their corespun construction where approximately 60% of thethread is a continuous filament bundle of polyester fibers. Core threads are recommended forsewing denim, workwear and uniforms, military garments, etc. that will be exposed todemanding finishing or end-use applications.For most non-apparel sewing applications, a Nylon or Polyester twisted multi-filament thread isrecommended include A&E’s Anefil ® Nylon and Anefil ® Polyester brands. If abrasion resistanceis the primary requirement, we recommend a Nylon thread. If UV and chemical resistance arerequired, we recommend polyester threads. A&E’s SunStop ® polyester thread is similar toAnefil ® Polyester but is made with special UV resistance dyes and finished with a UV inhibiter.THREAD SOLUTIONSThe threads mentioned above are available either bonded or soft. Most manufacturers usebonded threads in the needle positions because they has superior ply security and sewability.2