Dec 2002 - Lionel Collectors Club of America

Dec 2002 - Lionel Collectors Club of America

Dec 2002 - Lionel Collectors Club of America

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

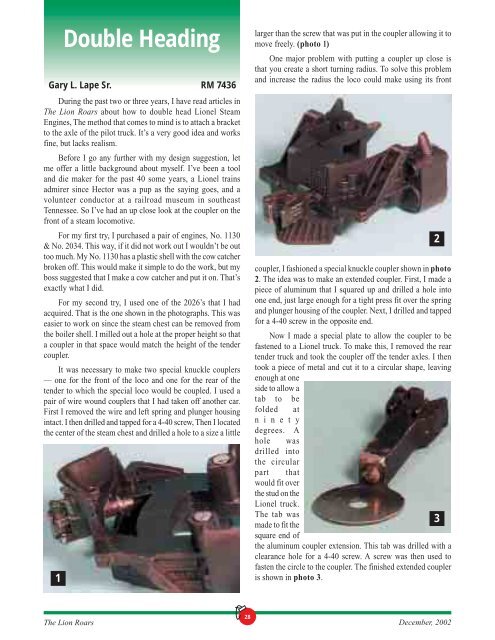

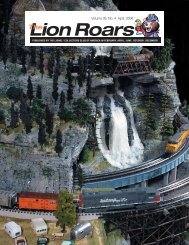

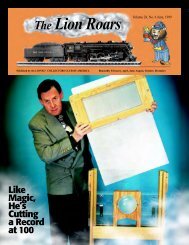

Double HeadingGary L. Lape Sr. RM 7436During the past two or three years, I have read articles inThe Lion Roars about how to double head <strong>Lionel</strong> SteamEngines, The method that comes to mind is to attach a bracketto the axle <strong>of</strong> the pilot truck. It’s a very good idea and worksfine, but lacks realism.Before I go any further with my design suggestion, letme <strong>of</strong>fer a little background about myself. I’ve been a tooland die maker for the past 40 some years, a <strong>Lionel</strong> trainsadmirer since Hector was a pup as the saying goes, and avolunteer conductor at a railroad museum in southeastTennessee. So I’ve had an up close look at the coupler on thefront <strong>of</strong> a steam locomotive.For my first try, I purchased a pair <strong>of</strong> engines, No. 1130& No. 2034. This way, if it did not work out I wouldn’t be outtoo much. My No. 1130 has a plastic shell with the cow catcherbroken <strong>of</strong>f. This would make it simple to do the work, but myboss suggested that I make a cow catcher and put it on. That’sexactly what I did.For my second try, I used one <strong>of</strong> the 2026’s that I hadacquired. That is the one shown in the photographs. This waseasier to work on since the steam chest can be removed fromthe boiler shell. I milled out a hole at the proper height so thata coupler in that space would match the height <strong>of</strong> the tendercoupler.It was necessary to make two special knuckle couplers— one for the front <strong>of</strong> the loco and one for the rear <strong>of</strong> thetender to which the special loco would be coupled. I used apair <strong>of</strong> wire wound couplers that I had taken <strong>of</strong>f another car.First I removed the wire and left spring and plunger housingintact. I then drilled and tapped for a 4-40 screw, Then I locatedthe center <strong>of</strong> the steam chest and drilled a hole to a size a little1larger than the screw that was put in the coupler allowing it tomove freely. (photo 1)One major problem with putting a coupler up close isthat you create a short turning radius. To solve this problemand increase the radius the loco could make using its frontcoupler, I fashioned a special knuckle coupler shown in photo2. The idea was to make an extended coupler. First, I made apiece <strong>of</strong> aluminum that I squared up and drilled a hole intoone end, just large enough for a tight press fit over the springand plunger housing <strong>of</strong> the coupler. Next, I drilled and tappedfor a 4-40 screw in the opposite end.Now I made a special plate to allow the coupler to befastened to a <strong>Lionel</strong> truck. To make this, I removed the reartender truck and took the coupler <strong>of</strong>f the tender axles. I thentook a piece <strong>of</strong> metal and cut it to a circular shape, leavingenough at oneside to allow atab to befolded atn i n e t ydegrees. Ahole wasdrilled intothe circularpart thatwould fit overthe stud on the<strong>Lionel</strong> truck.The tab wasmade to fit thesquare end <strong>of</strong>the aluminum coupler extension. This tab was drilled with aclearance hole for a 4-40 screw. A screw was then used t<strong>of</strong>asten the circle to the coupler. The finished extended coupleris shown in photo 3.2328The Lion Roars <strong>Dec</strong>ember, <strong>2002</strong>