UT4_Application Report - Uster Technologies

UT4_Application Report - Uster Technologies

UT4_Application Report - Uster Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

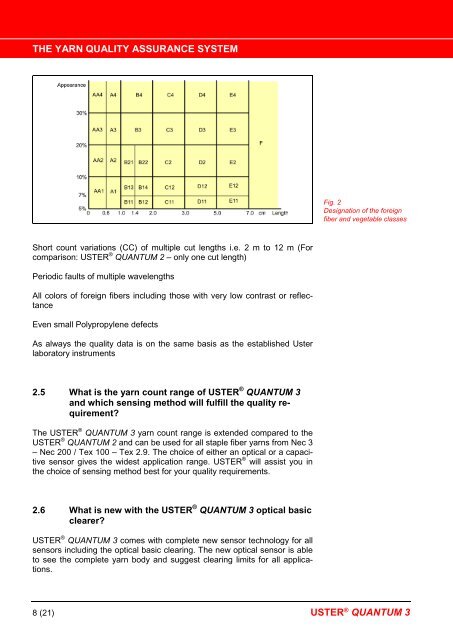

THE YARN QUALITY ASSURANCE SYSTEMFig. 2Designation of the foreignfiber and vegetable classesShort count variations (CC) of multiple cut lengths i.e. 2 m to 12 m (Forcomparison: USTER ® QUANTUM 2 – only one cut length)Periodic faults of multiple wavelengthsAll colors of foreign fibers including those with very low contrast or reflectanceEven small Polypropylene defectsAs always the quality data is on the same basis as the established <strong>Uster</strong>laboratory instruments2.5 What is the yarn count range of USTER ® QUANTUM 3and which sensing method will fulfill the quality requirement?The USTER ® QUANTUM 3 yarn count range is extended compared to theUSTER ® QUANTUM 2 and can be used for all staple fiber yarns from Nec 3– Nec 200 / Tex 100 – Tex 2.9. The choice of either an optical or a capacitivesensor gives the widest application range. USTER ® will assist you inthe choice of sensing method best for your quality requirements.2.6 What is new with the USTER ® QUANTUM 3 optical basicclearer?USTER ® QUANTUM 3 comes with complete new sensor technology for allsensors including the optical basic clearing. The new optical sensor is ableto see the complete yarn body and suggest clearing limits for all applications.8 (21) USTER ® QUANTUM 3